Waste disposal device including rotating cartridge coupled to hinged lid

a technology of a rotating cartridge and a hinged lid, which is applied in the field of waste disposal devices, can solve the problems of affecting the appearance of the waste package, the knotting of the tubing, and the inconvenience of the diaper genie diaper pail, and achieves the effect of convenient removal from the hamper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

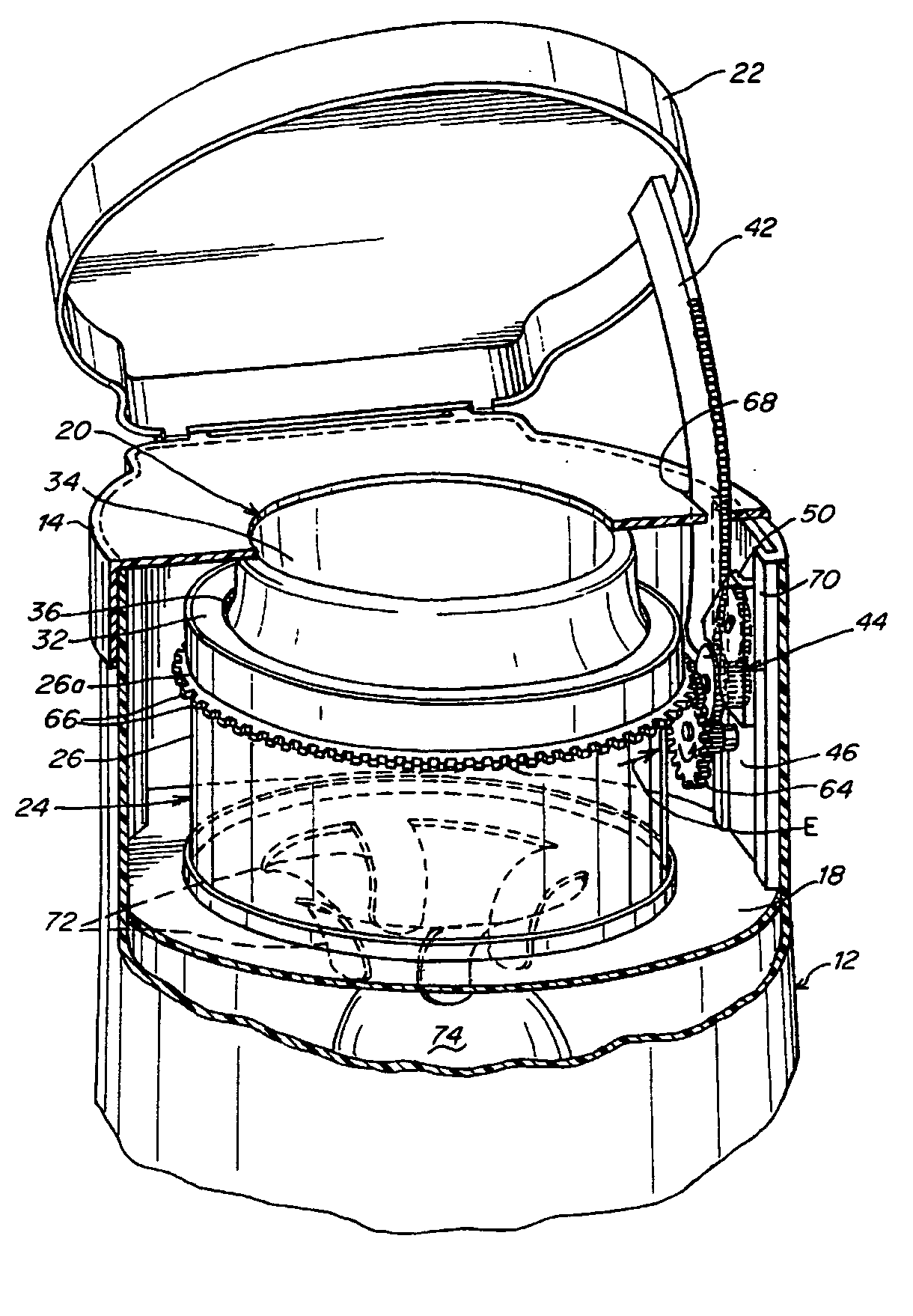

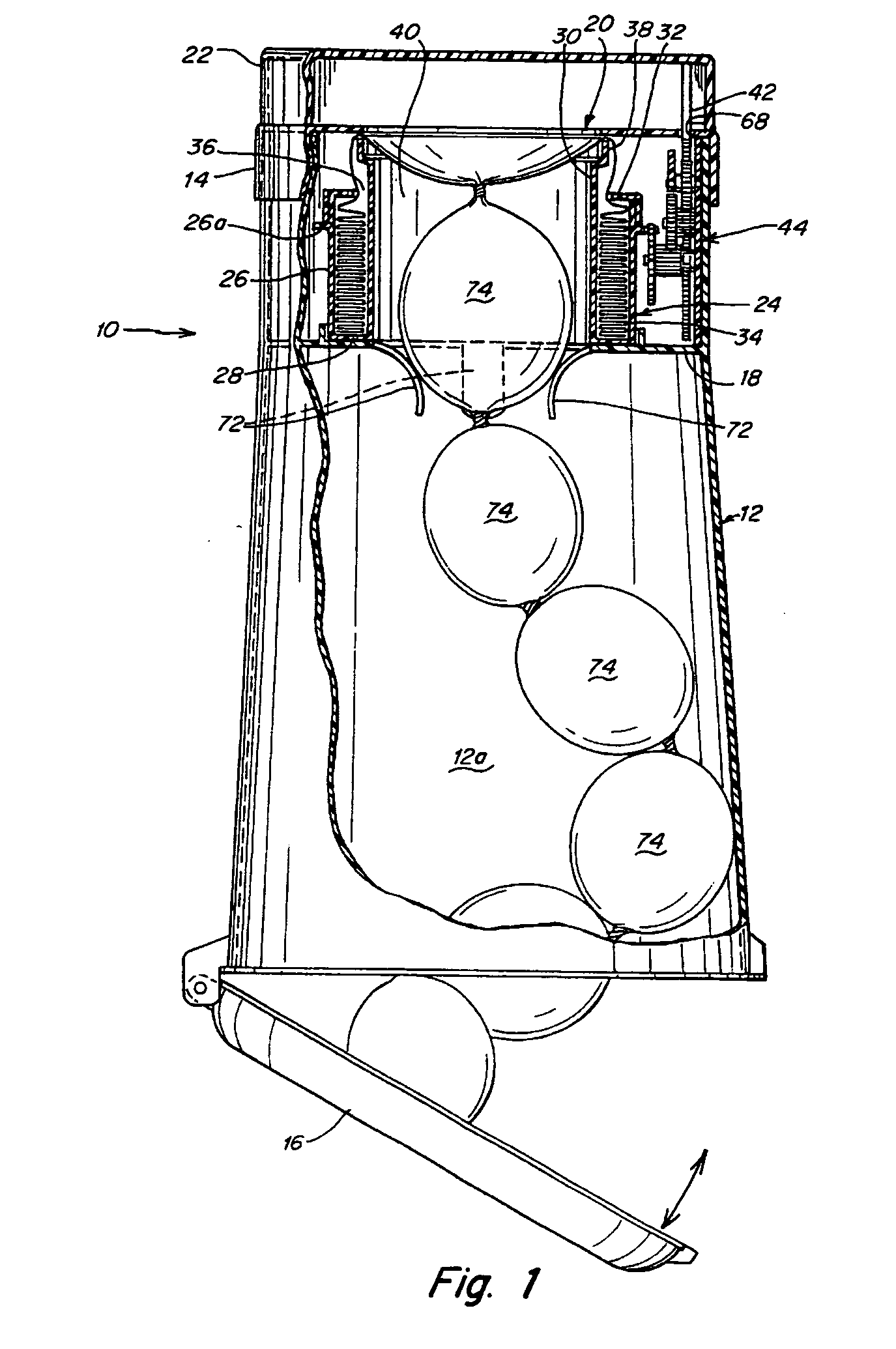

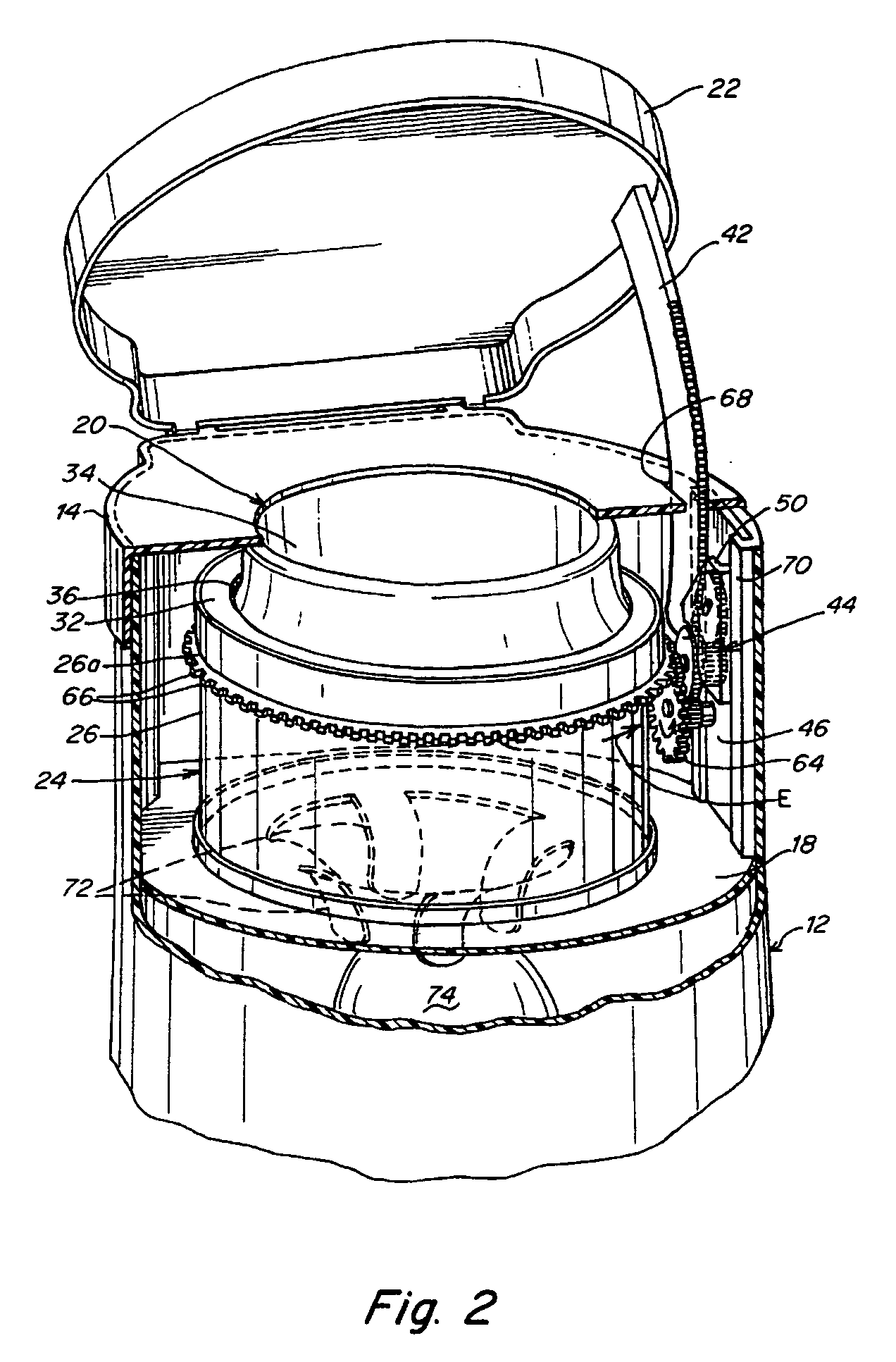

[0129] such a waste disposal device is shown in FIGS. 7-9 and it incorporates a rotation mechanism for rotating the waste package relative to the cartridge. The waste disposal device 80 includes a substantially cylindrical container 82 having an outer wall 84, and a base 86 arranged at a lower end of the outer wall 84. A removable hamper 88 is provided and has a wall 88a which also constitutes a part of the outer wall 84 of the container 82. The waste packages accumulate in the hamper 88 and the hamper 88 is removed from the container 82 and emptied when full. Since the hamper 88 comes into direct contact with the waste packages and is liable to become dirty, it is advantageous that it is detachable from the container 82 so that it can be easily cleaned, possibly by placing it in a dishwasher.

[0130] A lid 22 is pivotally connected to the outer wall 84 so as to be movable between an open position in which a waste insertion opening 20 is exposed to enable insertion of a waste package ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com