Pump diaphram rupture detection

a diaphragm and pump technology, applied in the direction of engine diaphragms, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of wear and failure of each layer independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

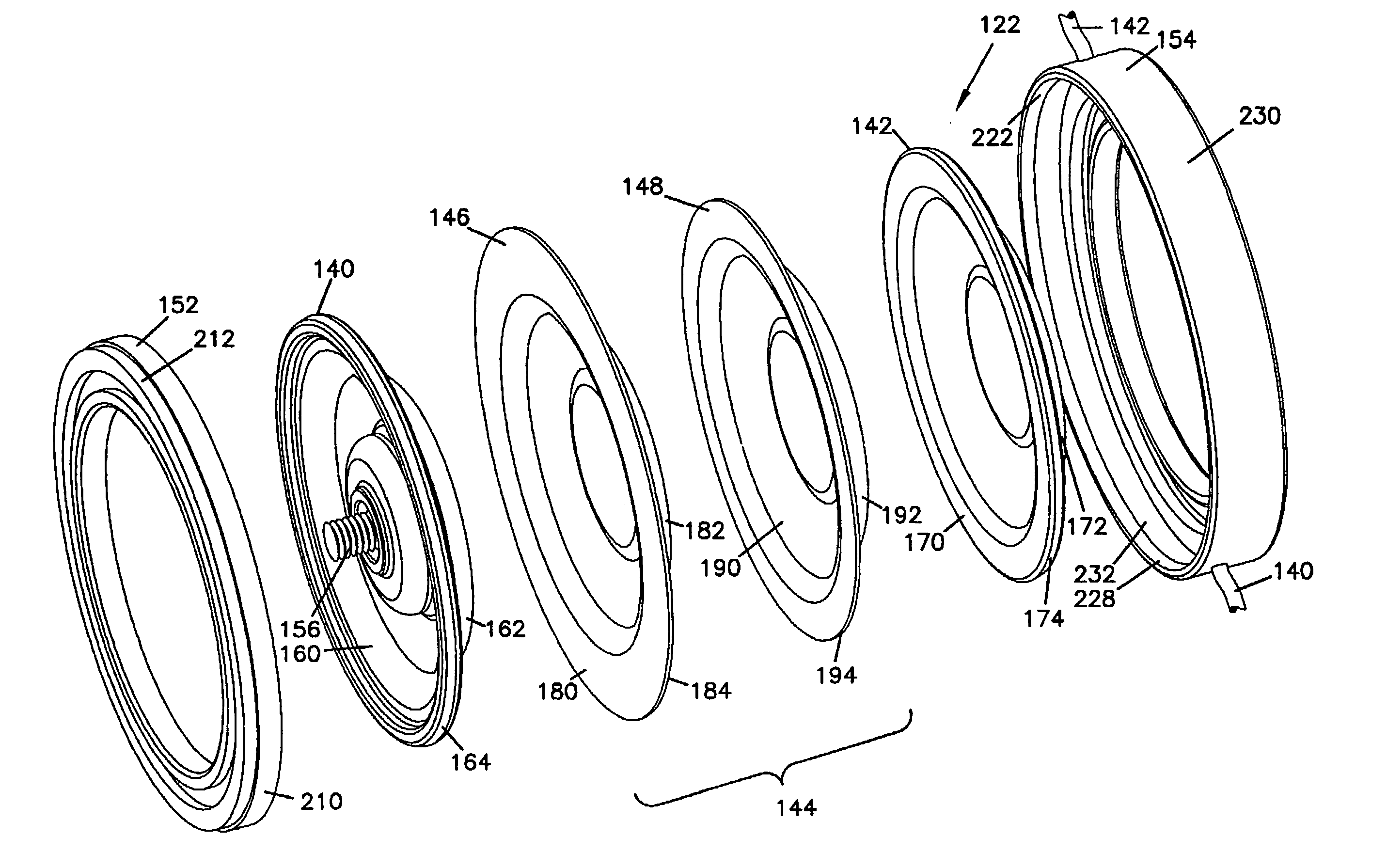

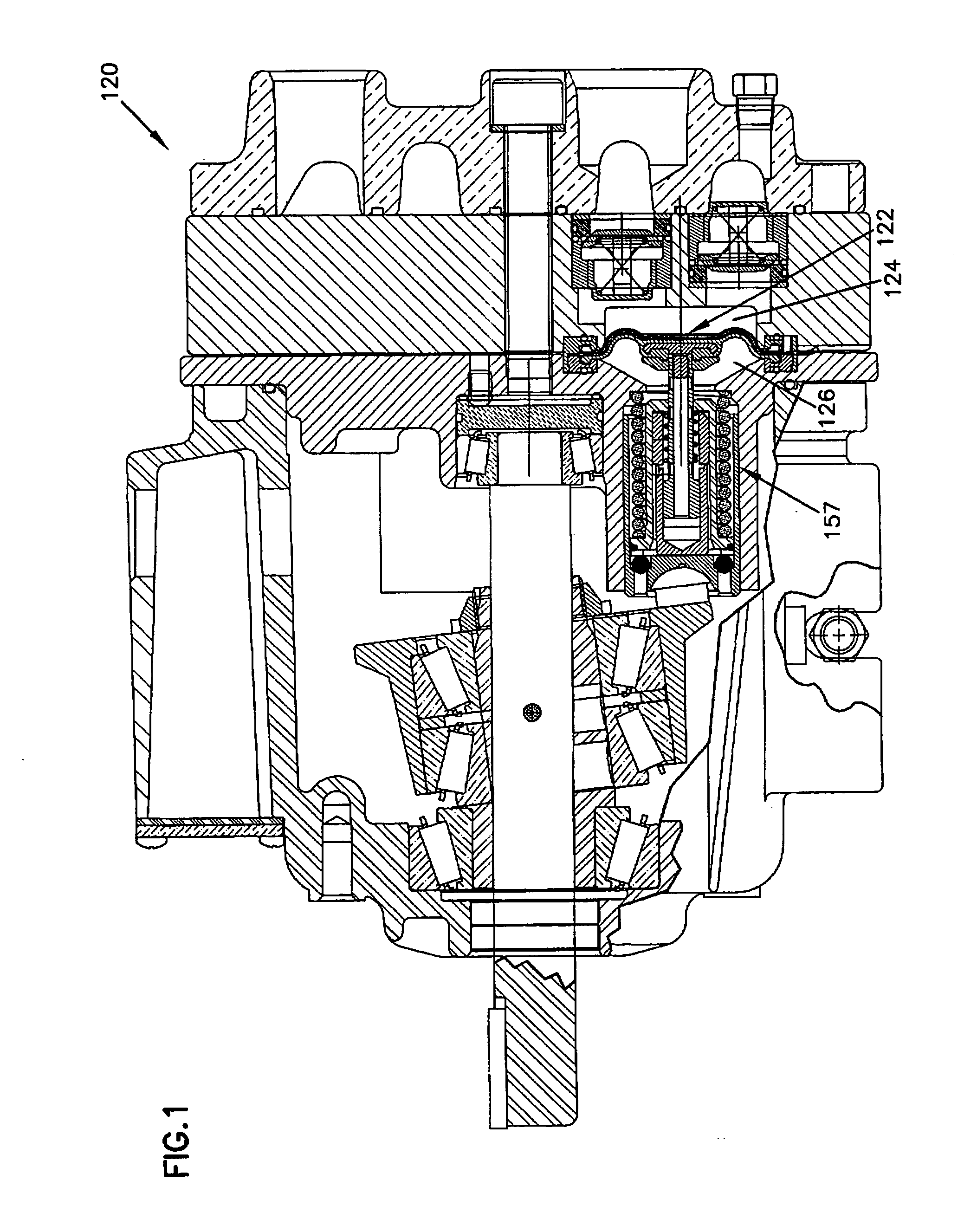

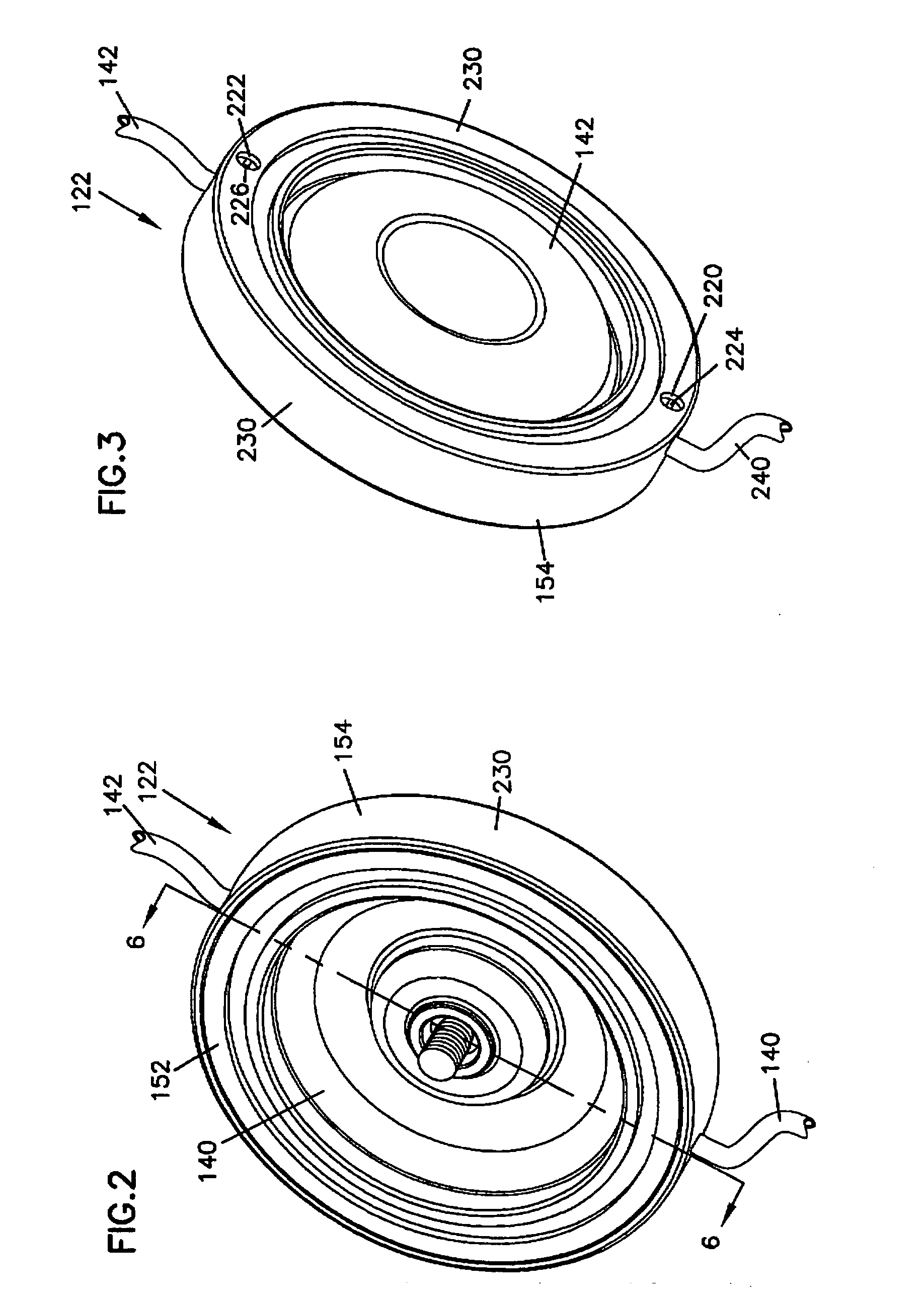

[0041] The present invention generally relates to a diaphragm for a hydraulically driven pump that is an improvement to the conventional diaphragms described above. Like parts are designated by like numerals. Improved parts are distinguished and described. The invention generally relates to hydraulically driven pumps, and more specifically relates to diaphragms for hydraulically driven pumps and the detection of failure in such diaphragms. The diaphragm includes at least three elastomeric layers made of high strain resistant materials. The layer positioned between the other two layers includes a conductive trace embedded therein. Changes in the conductive trace resistance is monitored while the diaphragm is in use. When the resistance values reach a certain predetermined level that indicates failure in one or more of the diaphragm layers, or the possibility of a failure occurring, a failure signal is generated. A rupture of the middle layer will also be detected since a break in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com