Compression cooling system and method for evaluating operation thereof

a cooling system and compression technology, applied in the field of compression conditioning systems, can solve the problems of affecting the seal nature of the system and affecting the cooling effect of the system, and achieve the effect of reducing the risk of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

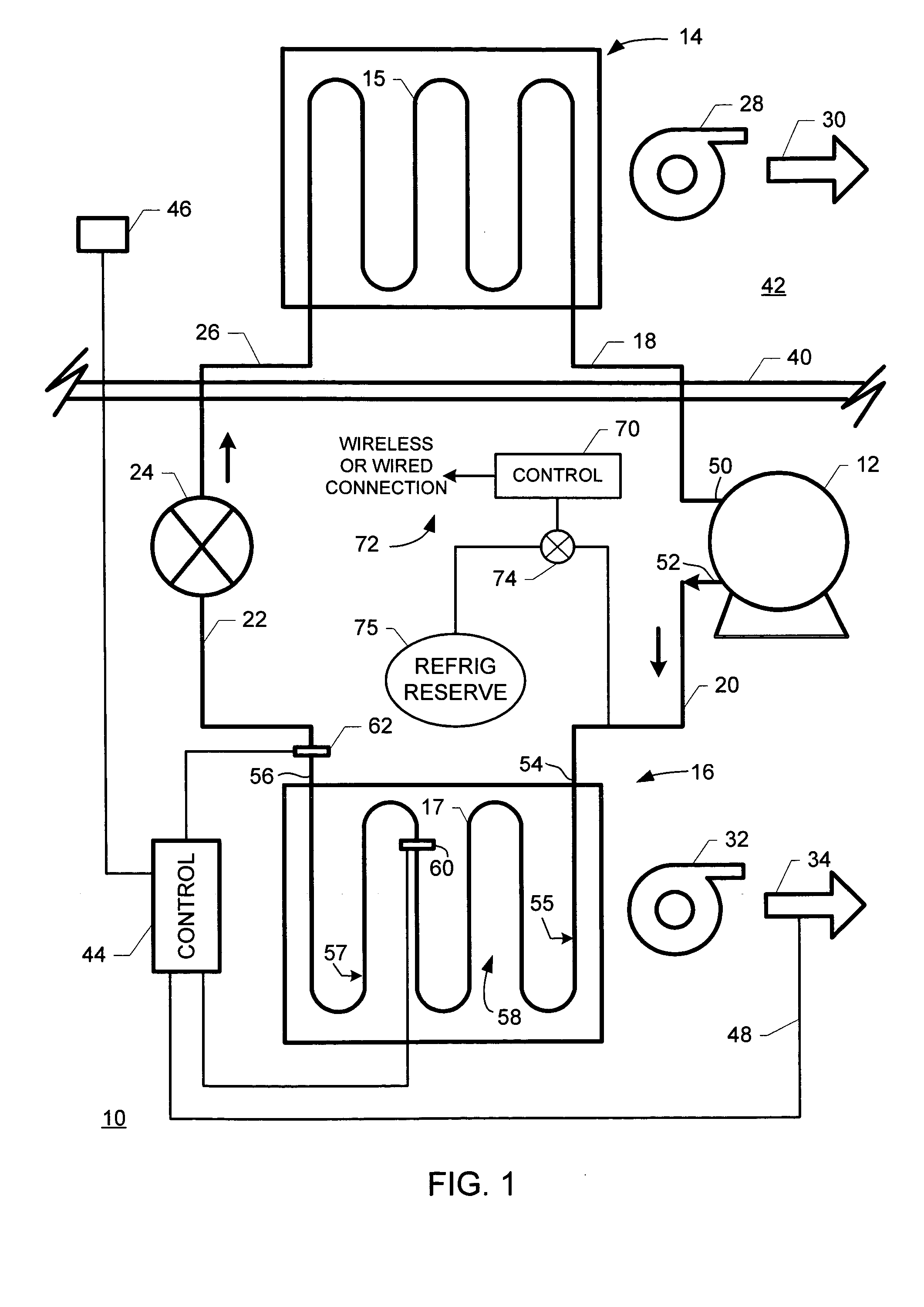

[0021]FIG. 1 is a schematic diagram illustrating a compression cooling system configured according to the present invention. In FIG. 1, a cooling system 10 includes a compressor 12, an evaporator 14 and a condenser 16. A fluid line 18 fluidly couples evaporator 14 with compressor 12. A fluid line 20 fluidly couples compressor 12 with condenser 16. A fluid line 22 fluidly couples condenser 16 with an expansion valve 24. A fluid line 26 fluidly couples expansion valve 24 with evaporator 14. By “fluidly couples” it is meant that fluid flows substantially freely within fluid lines 18, 20, 22, 26 to transport refrigerant (not shown separately in FIG. 1) among evaporator 14, condenser 112, condenser 16 and expansion valve 24. A blower fan 28 draws air across evaporator 14 generally in the direction indicated by arrow 30. A blower fan 32 draws air across condenser 16 generally in the direction indicated by arrow 34.

[0022] A building wall 40 bounds a building interior space 42 that is cool...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap