Golf bag cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

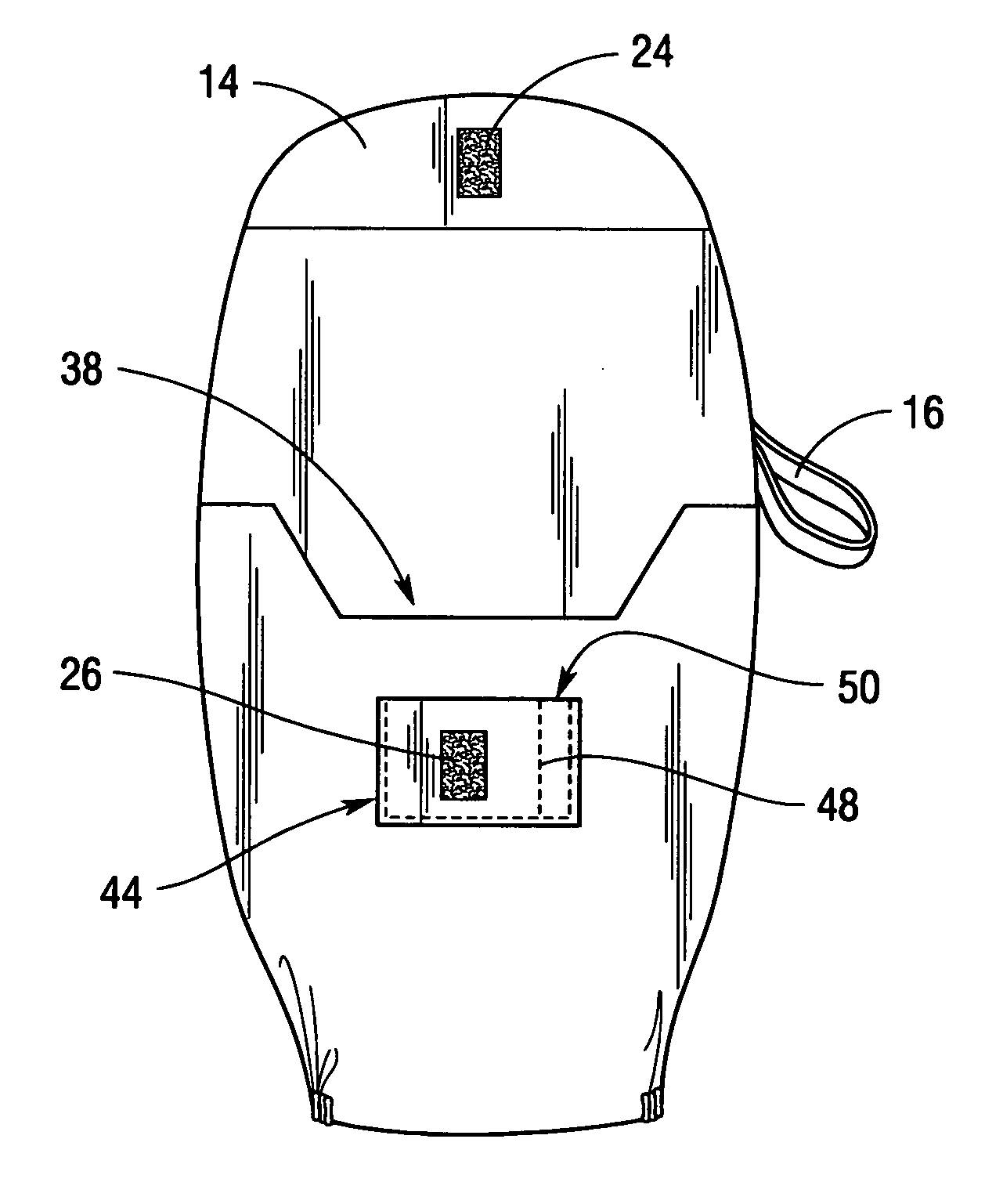

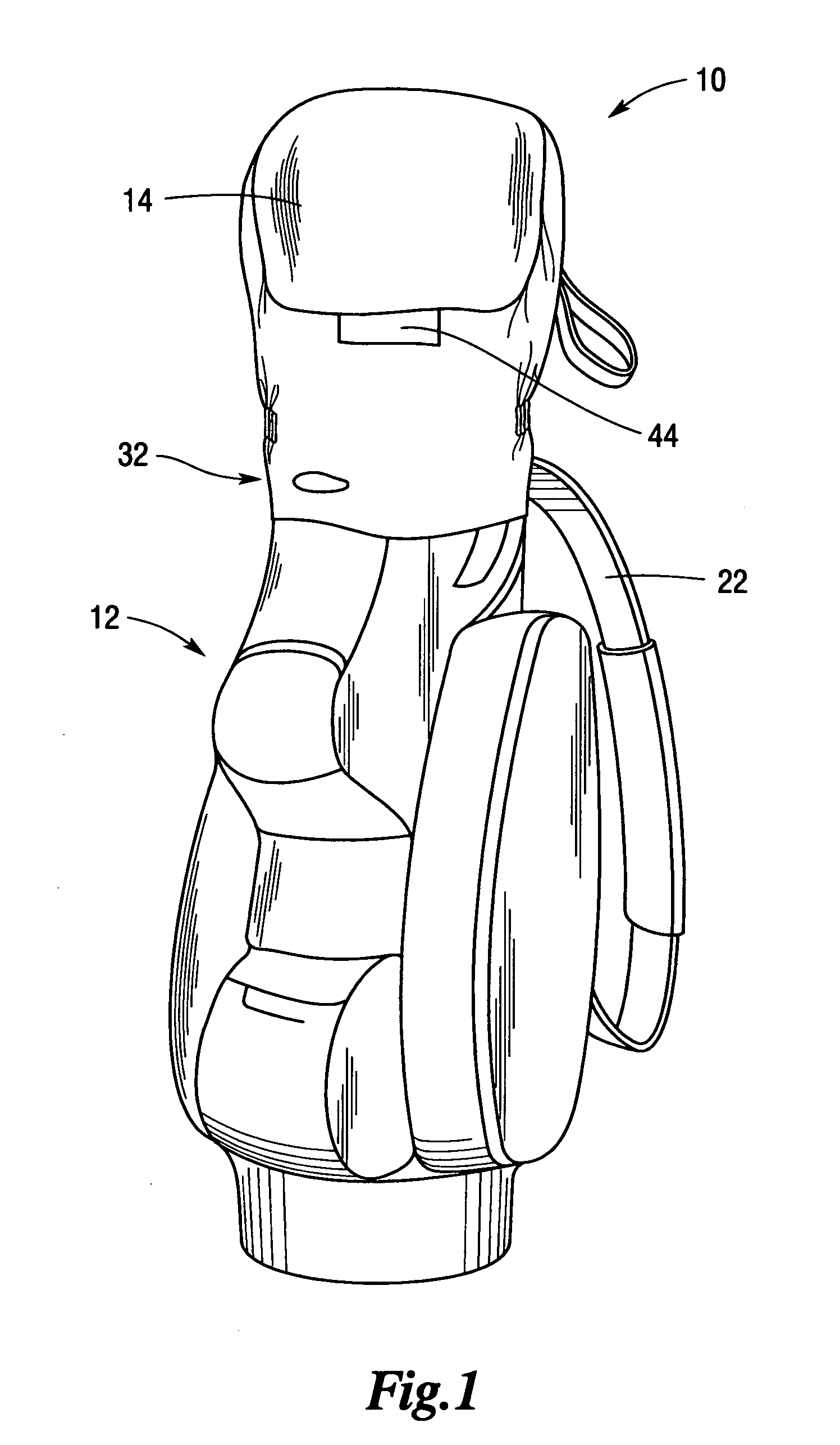

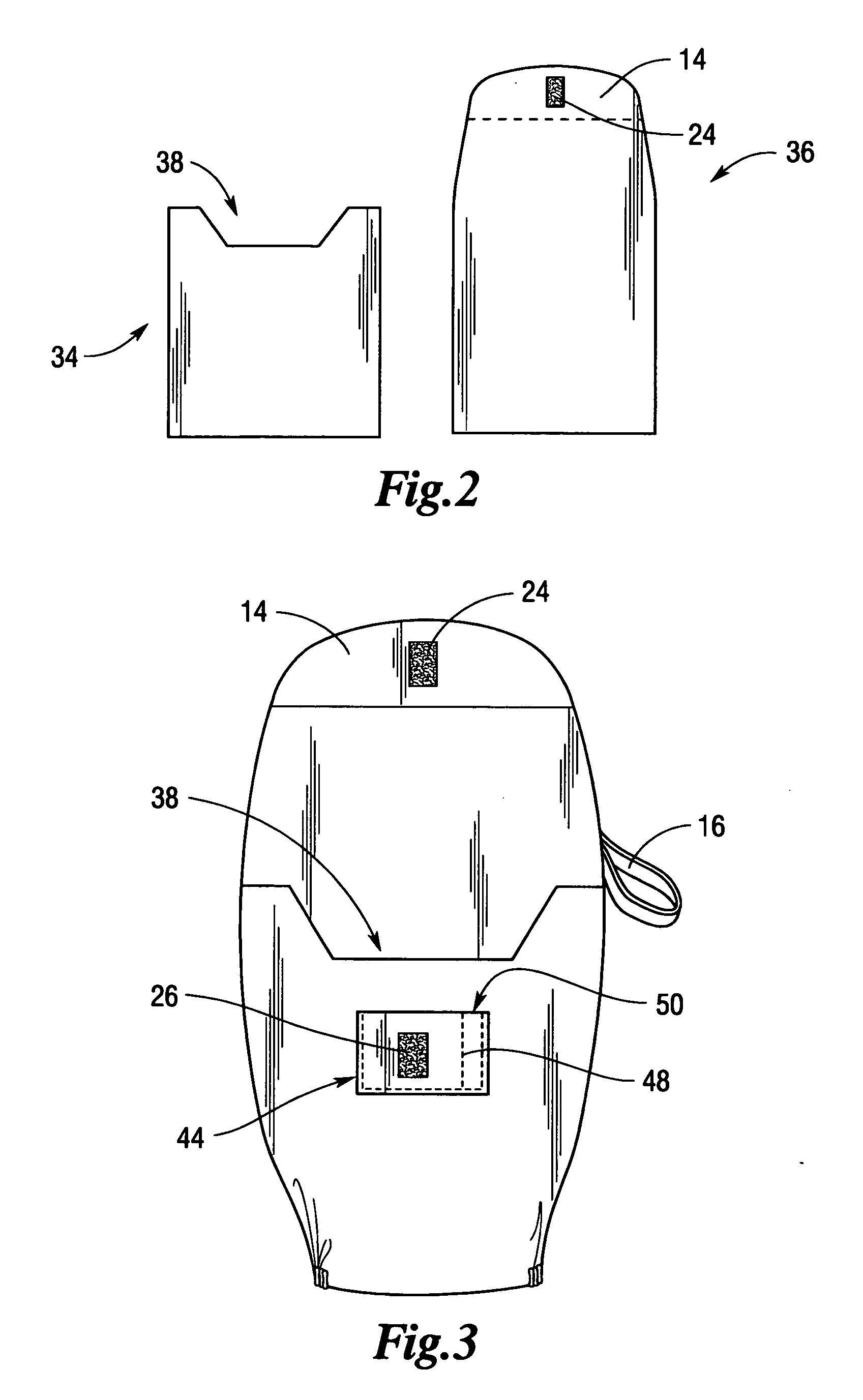

[0018] Referring now to FIG. 1, the invention provides a flexible golf bag cover 10 of fabric for protecting the interior and contents of a golf bag 12 from dust, contaminants and precipitation. The golf bag cover 10 includes an openable top (closure) flap 14 that is in parallel alignment with an opening in a golf bag 12, and a cuff with elastic 16 and strap assemblies 18, 20 to accommodate golf bags and strap handles 22 of varying configurations. Velcro 24 strap closure means and associated flap 28, 30 arrangements allow access to specific sections of a golf bag 2 and accommodation of all bag types. A golf bag 2 is shown as a common type with an open top surrounded by a peripheral rim 32 and a carrying strap 22 extending approximately laterally from the rim 32.

[0019] As shown in FIG. 2, the main portion of the golf bag cover 10 according to the invention is manufactured from two substantially rectangular sections of fabric 34 and 36, which are affixed to each other along the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com