Method and apparatus for reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The use of the terms first, second, etc. do not denote any order or importance, but rather the terms first, second, etc. are used to distinguish one element from another, and the terms “a” and “an” herein do not denote a limitation of quantity, but rather denote the presence of at least one of the referenced item. It is noted that this application is described in relation to use in relation to an exhaust stream. This exhaust stream can be any exhaust stream, e.g., a vehicle exhaust stream (such as an automobile, passenger vehicle, truck, or the like), a cogenerator exhaust stream, or the like.

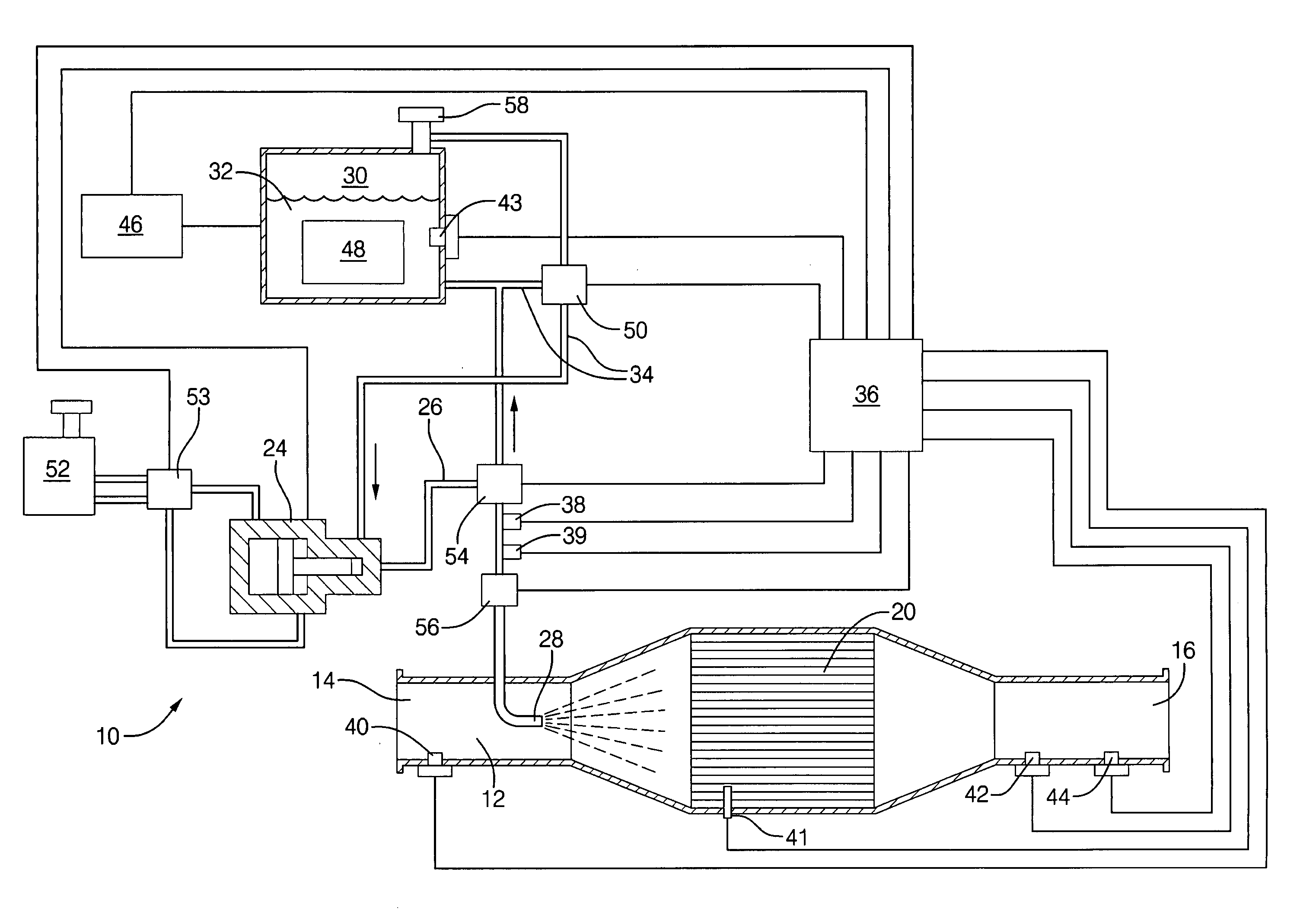

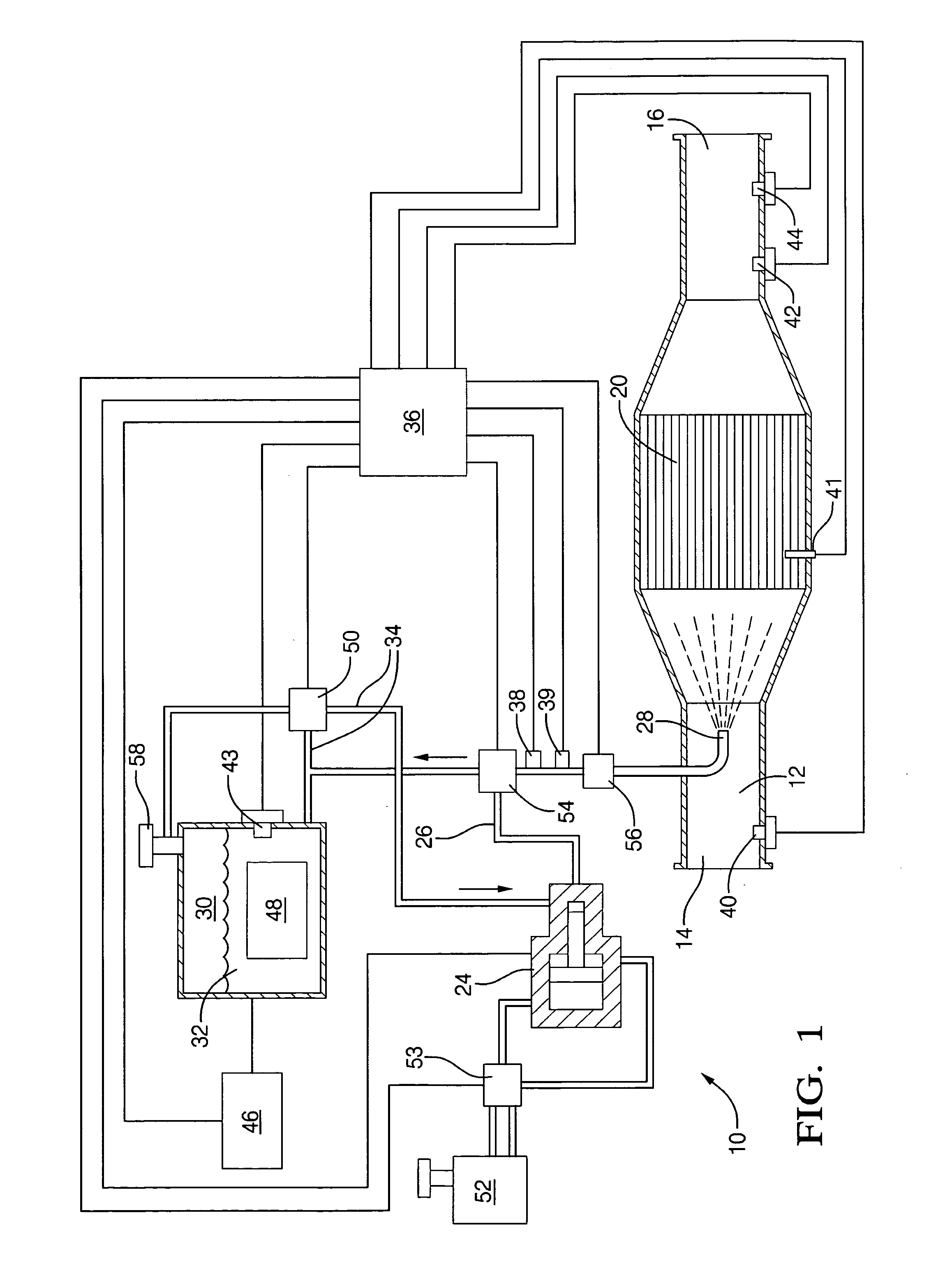

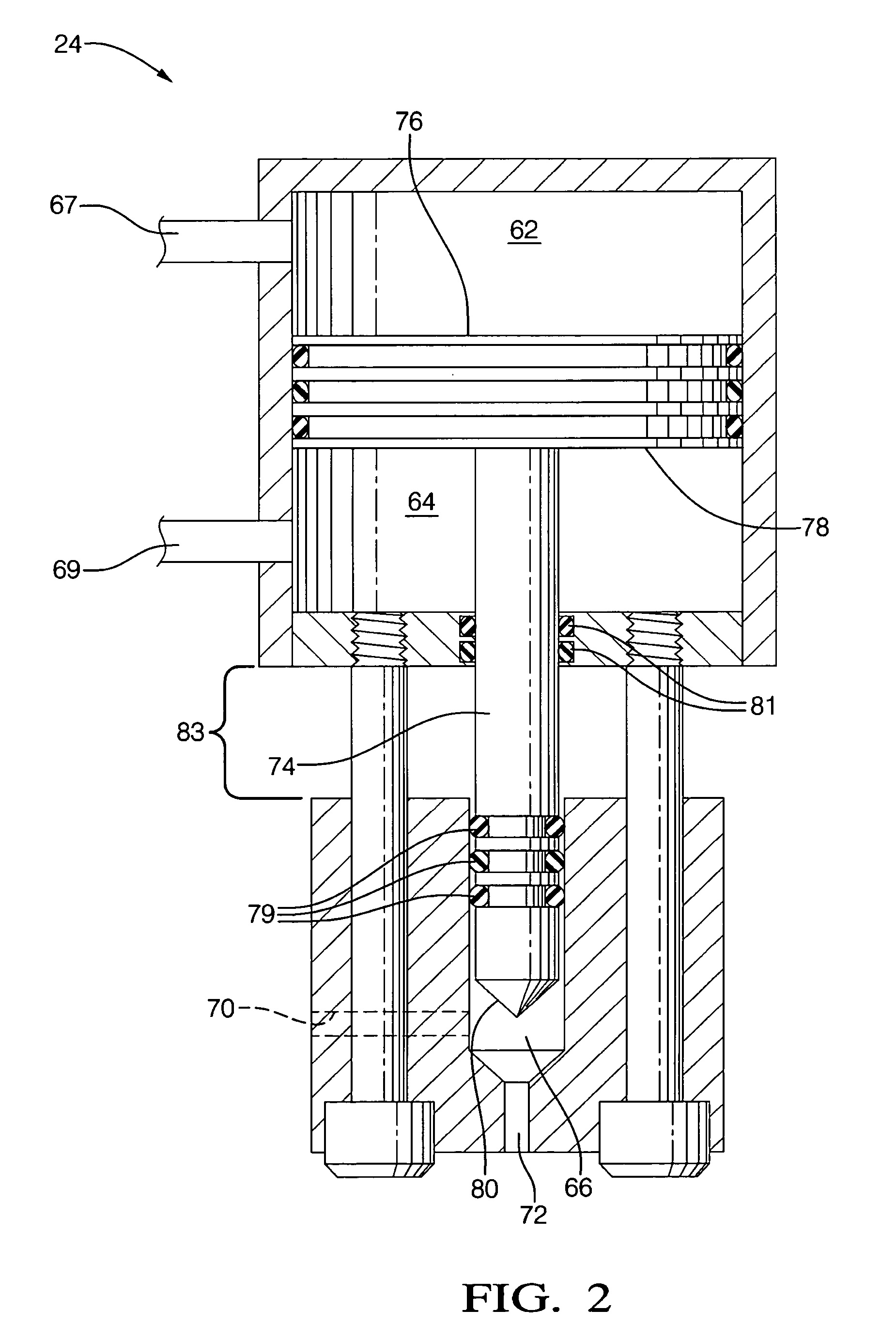

[0019] Disclosed herein is a reductant system, e.g., for injecting reductant (e.g., urea, ammonia, hydrocarbons, or the like) upstream of or into an exhaust treatment device, such as for the removal of NOx from an exhaust stream. Referring now to FIG. 1, a schematic illustration of a system 10 is shown. The system 10 can include an exhaust system of a vehicle as well as parts of other v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com