Reversible rotatable cutting and ironing board combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

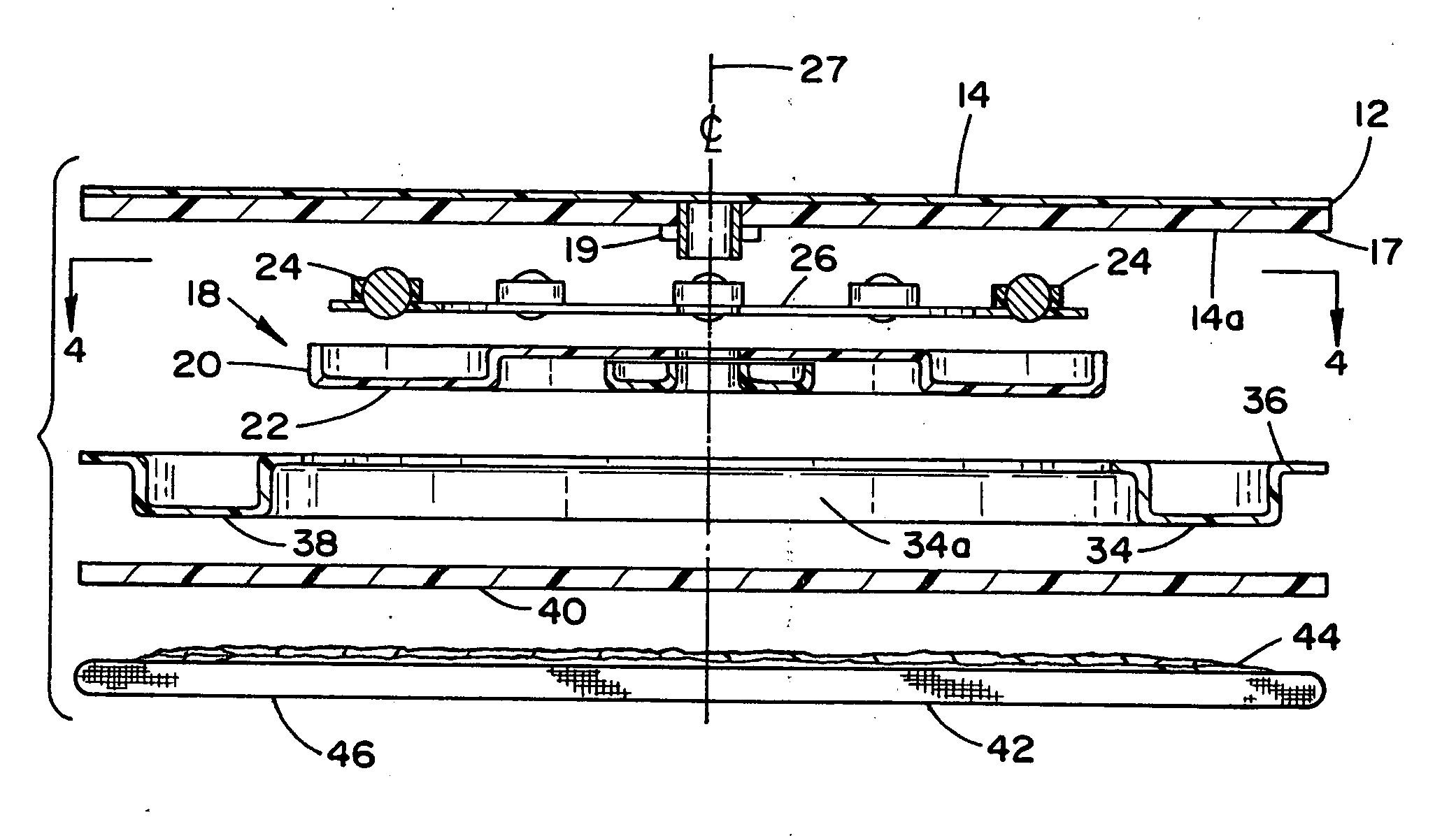

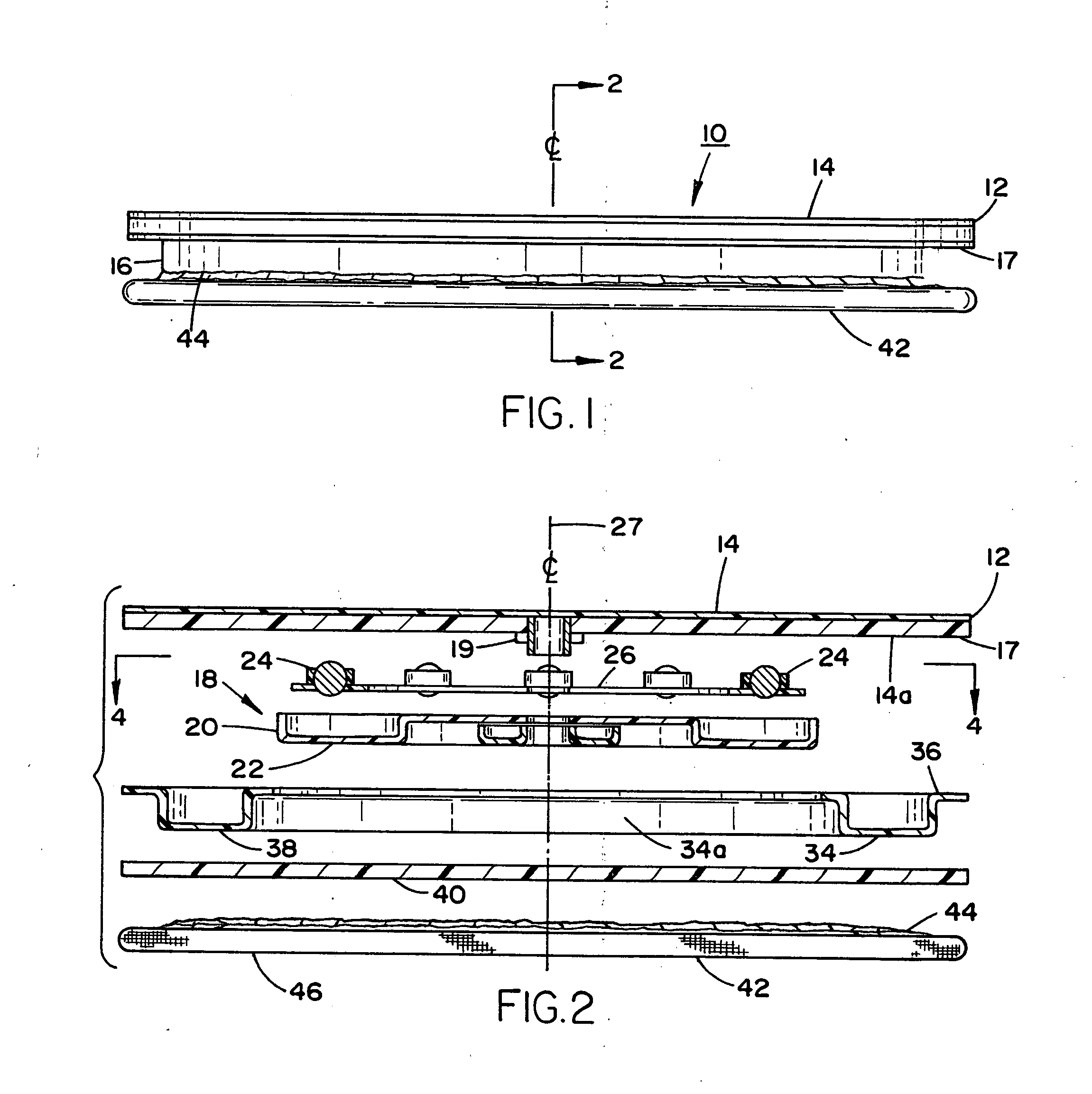

[0024] Referring in detail to the drawings, particularly FIG. 1, there is illustrated a turntable assembly 10 constituted of a circular disk member 12 having a cutting surface 14 as also shown in FIG. 3 of the drawings, and which is constituted of a die cut and hot stamp decorated top cutting board of a rigid plastic material. The cutting surface 14 may be of a so-called “self-healing nature” when subjected to cutting action.

[0025] Laminated thereto is a stock race assembly 16 comprising a disk-shaped plate member 17 of rigid plastic, which is attached to the opposite surface 14a of member 12 by gluing as is well known in the art, and which on the opposite side thereof has a grommet and sleeve member 19 rotatably connected to a stock race unit 18 constituted of plastic material. As shown in FIG. 2, in the exploded transverse sectional view thereof, taken along line 2-2 in FIG. 2, the stock race includes a first member 20 of a molded plastic ring-shaped configuration, having an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com