System and method for outsource supplier management

a supplier management and supplier technology, applied in the field of inventory control systems, can solve the problems of increasing inventory carrying costs, prohibitive costs of carrying large amounts of inventory, and increasing costs of inventory facilities, so as to facilitate changes, facilitate efficient order processing, and facilitate improved order communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

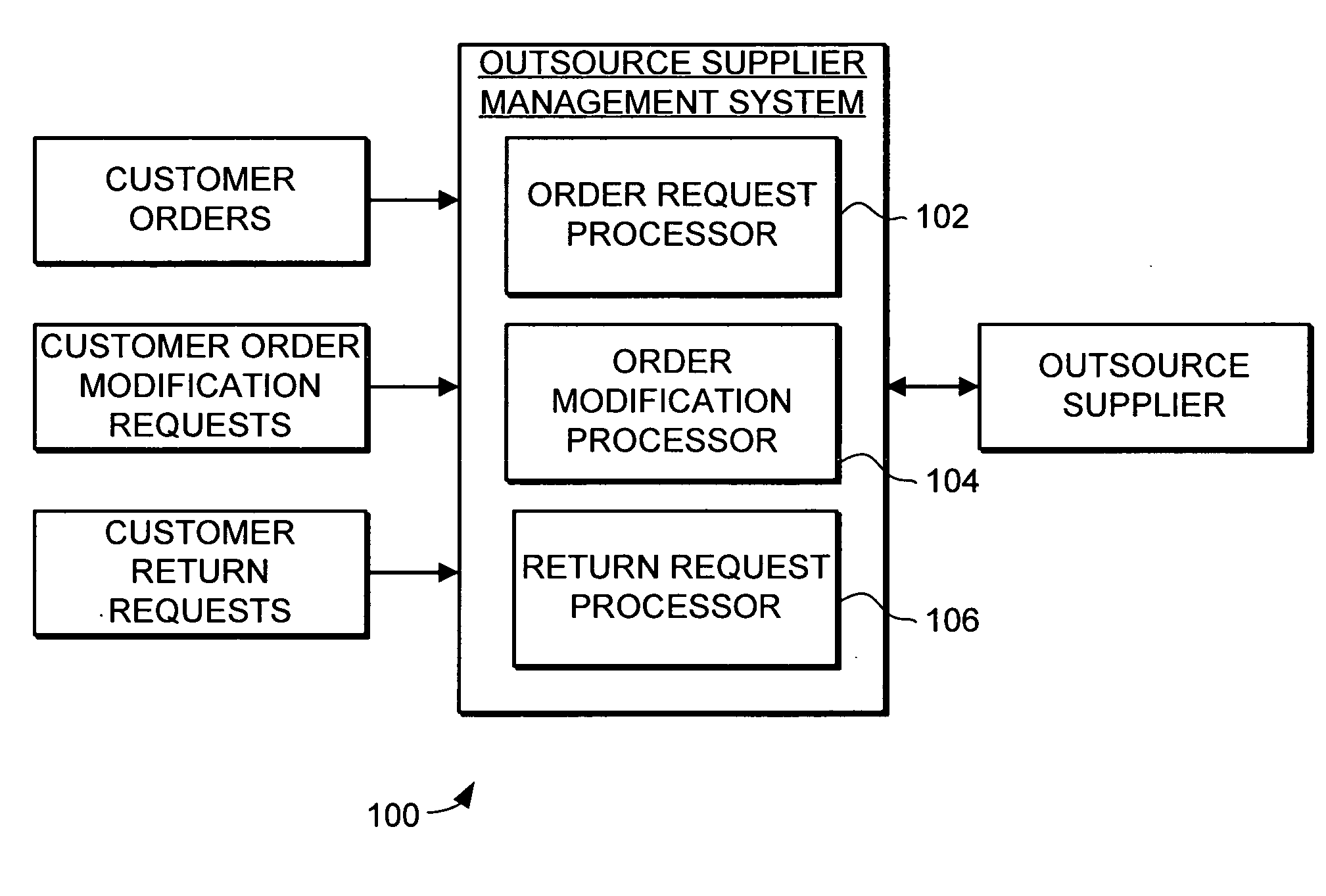

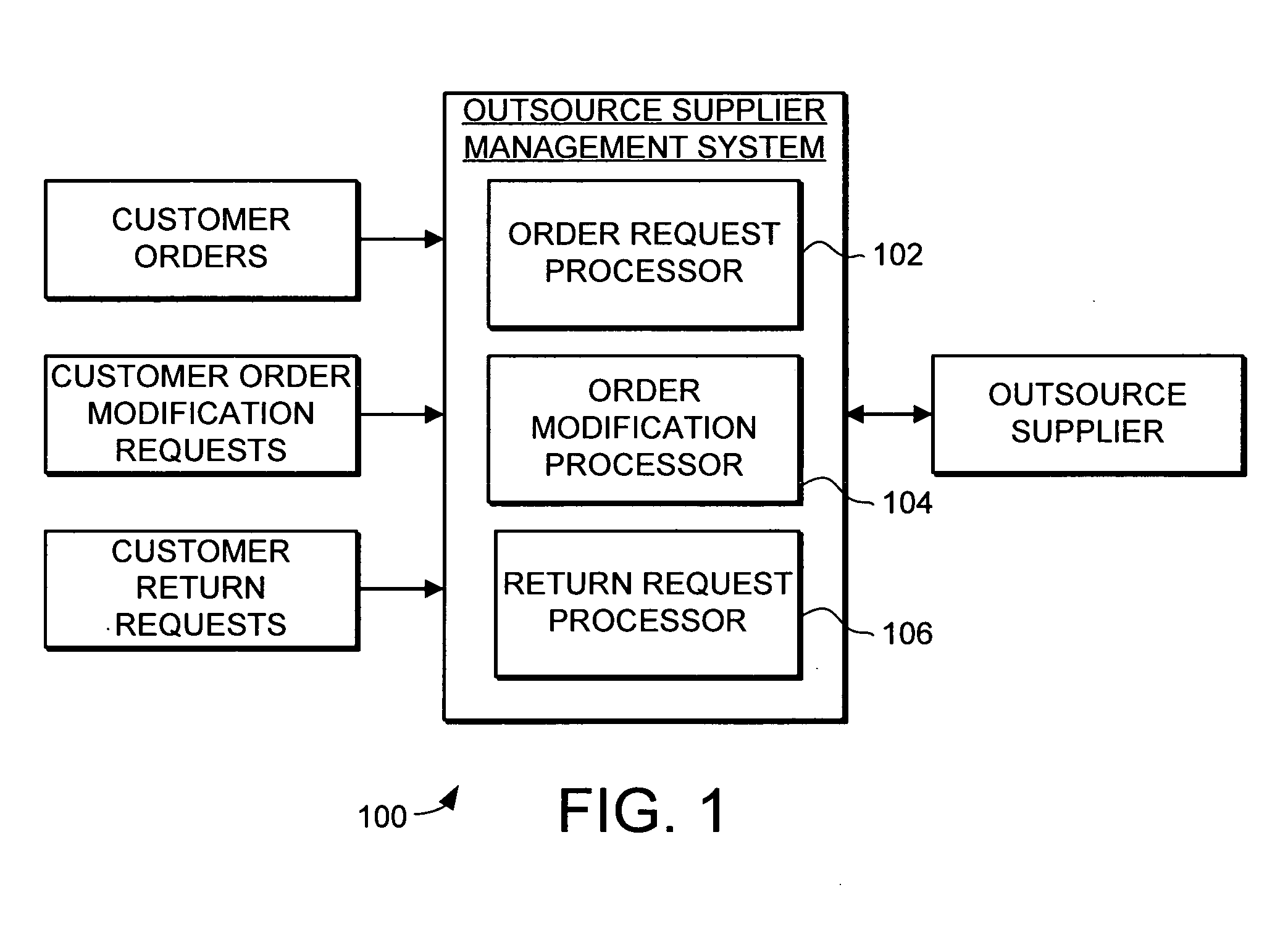

[0017] The present invention provides a system and method for outsource supplier management. The system and method facilitates improved order communication between customers, sellers and outsource suppliers. Turning now to FIG. 1, an outsource supplier management system 100 is illustrated schematically. The outsource supplier management system 100 includes an order request processor 102, and order modification processor 104, and a return request processor 106. The outsource supplier management system 100 receives customer orders, customer order modification requests, and customer return requests. The outsource supplier management system 100 processes the orders and requests, communicating with the outsource supplier and the customer as needed to facilitate outsource order processing.

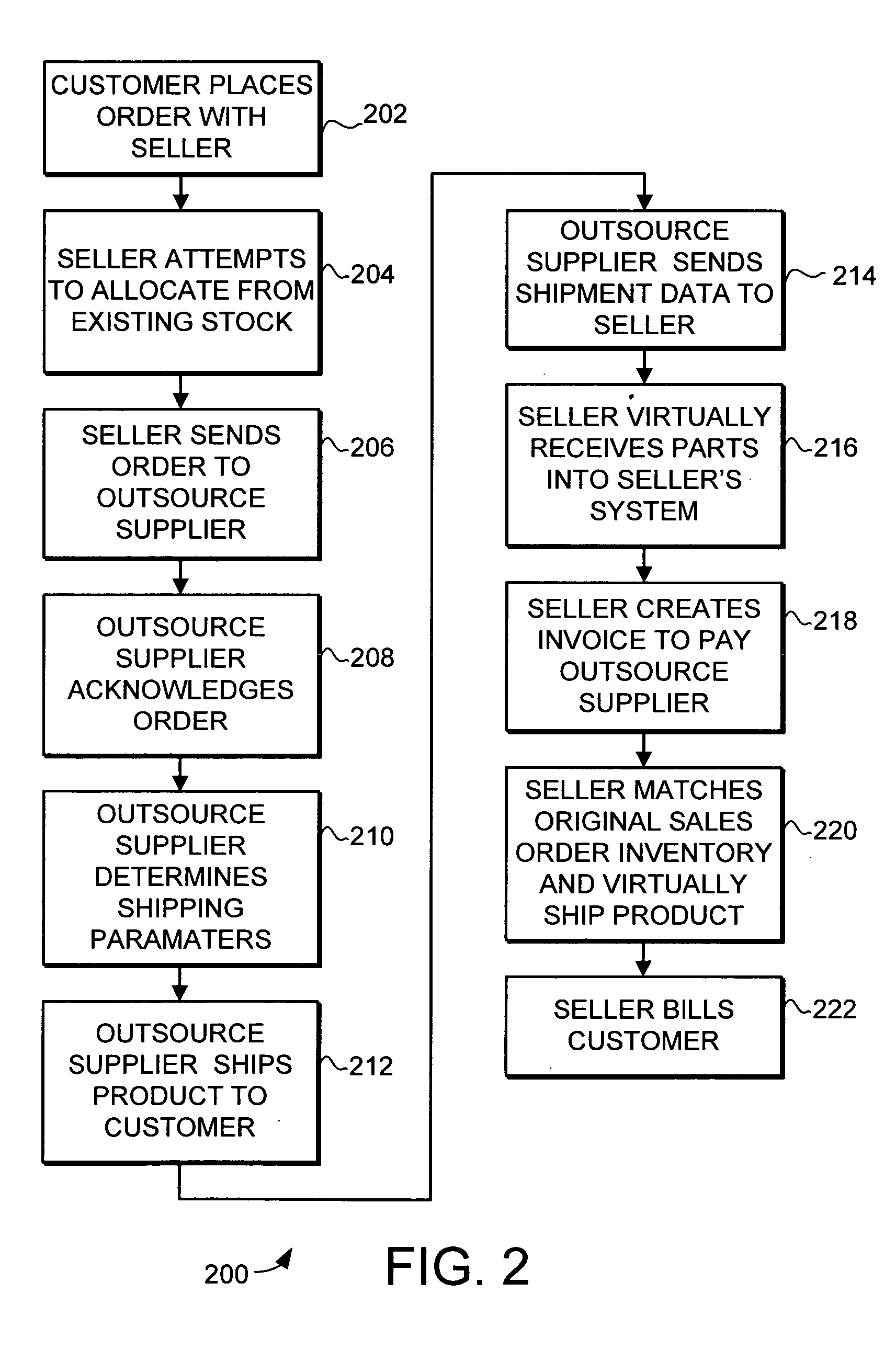

[0018] Specifically, during order processing the outsource supplier management system 100 automatically receives the order from the customer and passes the order to the outsource supplier along with ord...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap