Rotary coke drum un-heading valve

a technology of unheading system and coke drum, which is applied in the direction of sliding valve, coke oven, mechanical equipment, etc., can solve the problems of high risk, high risk, and high risk of workers being exposed to hazardous materials and fumes, and achieve the effect of compact and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

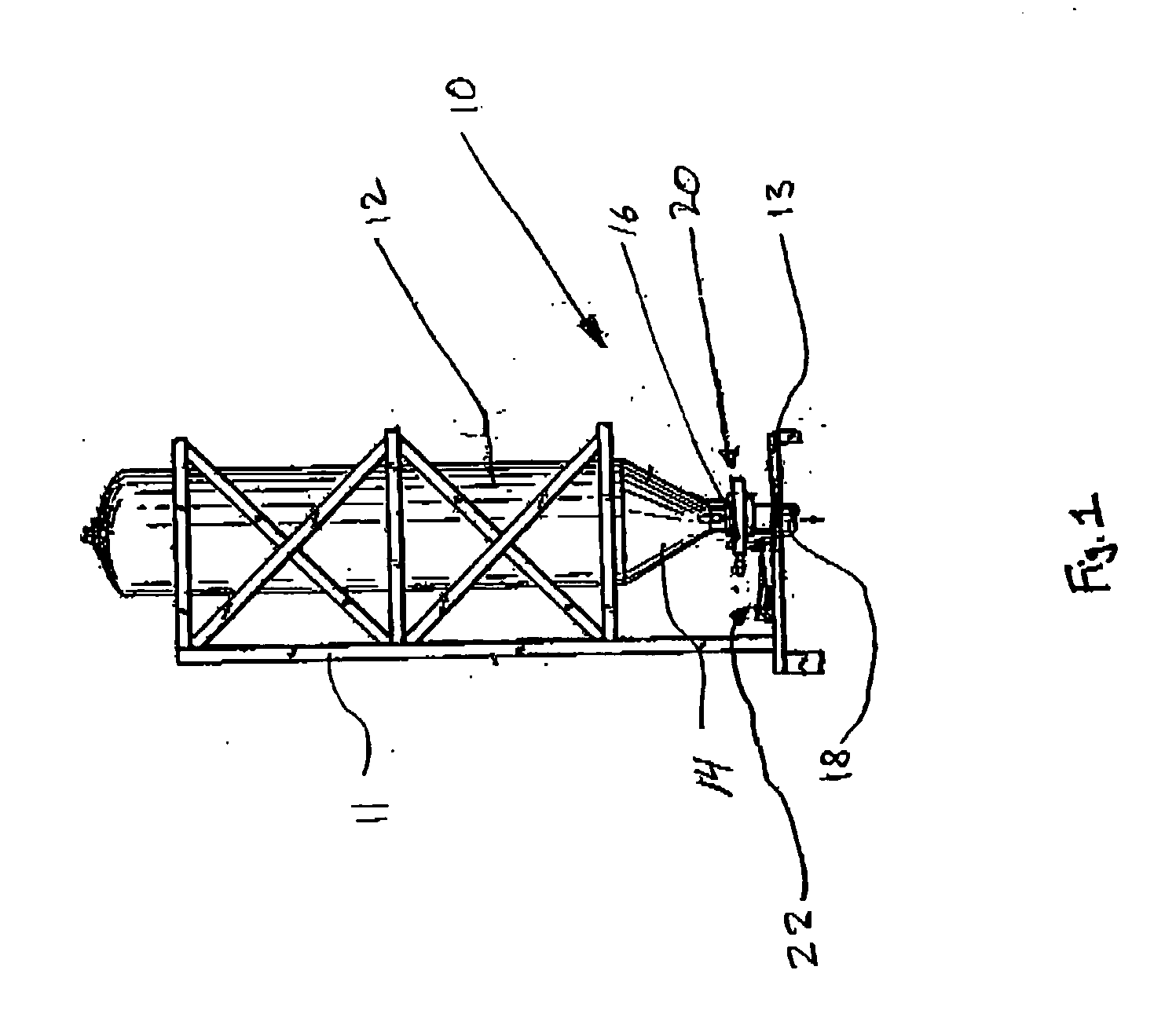

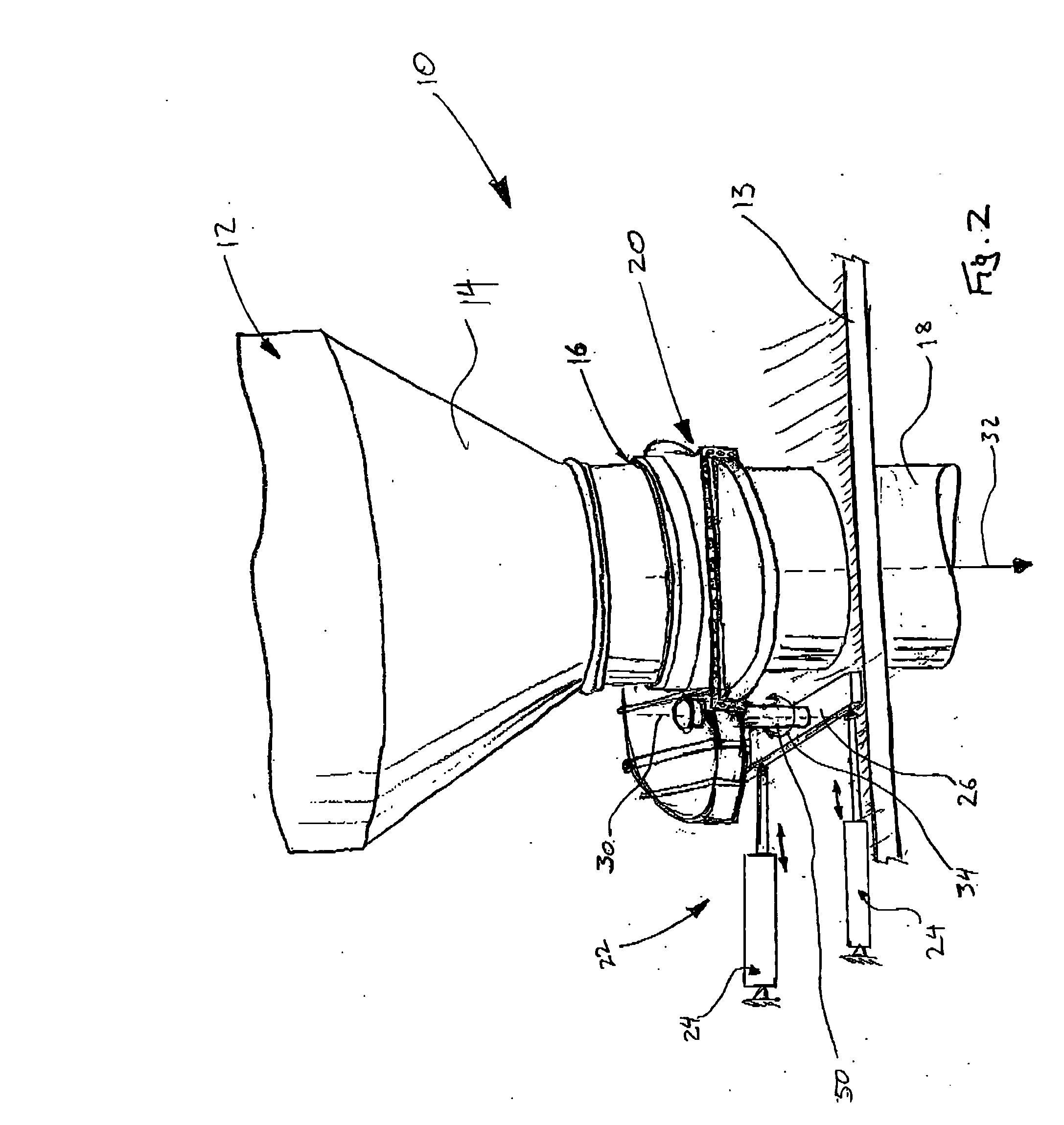

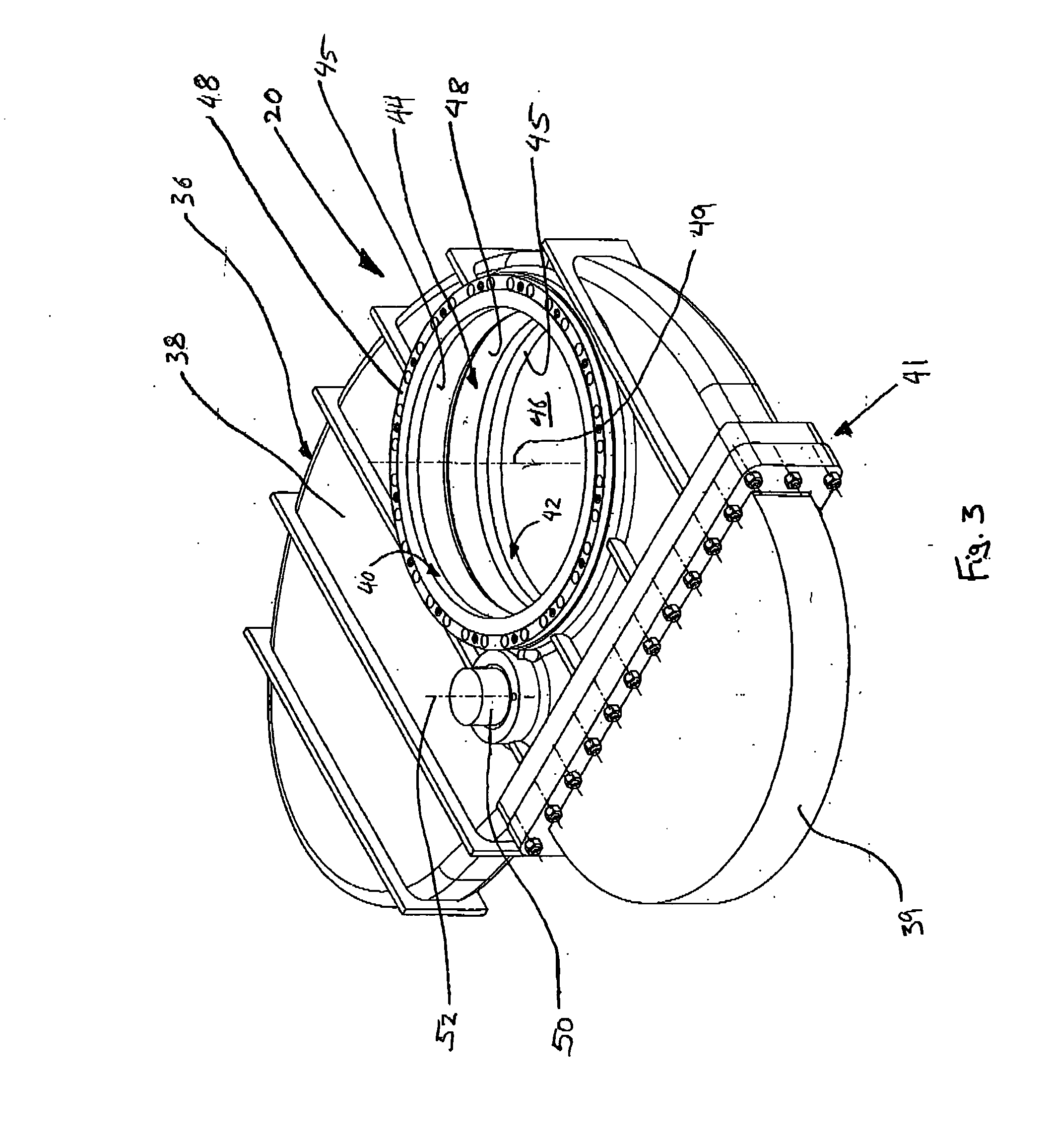

[0028] As schematically shown in FIG. 1, a vertically oriented pressure vessel, such as a coke drum 12 as employed in the delayed coking process of a petroleum refinery, is supported by an adjacent support structure 11 mounted on a lower platform 13 below the coke drum 12. Such delayed coking drums typically have a diameter between about 20 and 30 feet and stand about 75 to 100 feet tall. The lower portion 14 of the coke drum 12 may have a conical shape and terminates in a lower flange 16 which may be in the range of 5 to 10 feet in diameter and which defines a bottom orifice of the coke drum 12 through which the contents of the drum may be evacuated during the decoking cycle. A coke drum un-heading valve 20 is fastened to said lower flange 16 in fluid flow communication with the orifice defined in the base of the coke drum. The un-heading valve 20 is selectively operable to seal the orifice while the coke drum is being filled and open the drum orifice such that mass flow out of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap