Rapid measuring device of width of tobacco shred

A measuring device and leaf wire technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor test result stability, large number of measuring leaf wires, high labor intensity, etc., and achieves enhanced quality assurance capability and compact structure. Reliable, effort-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

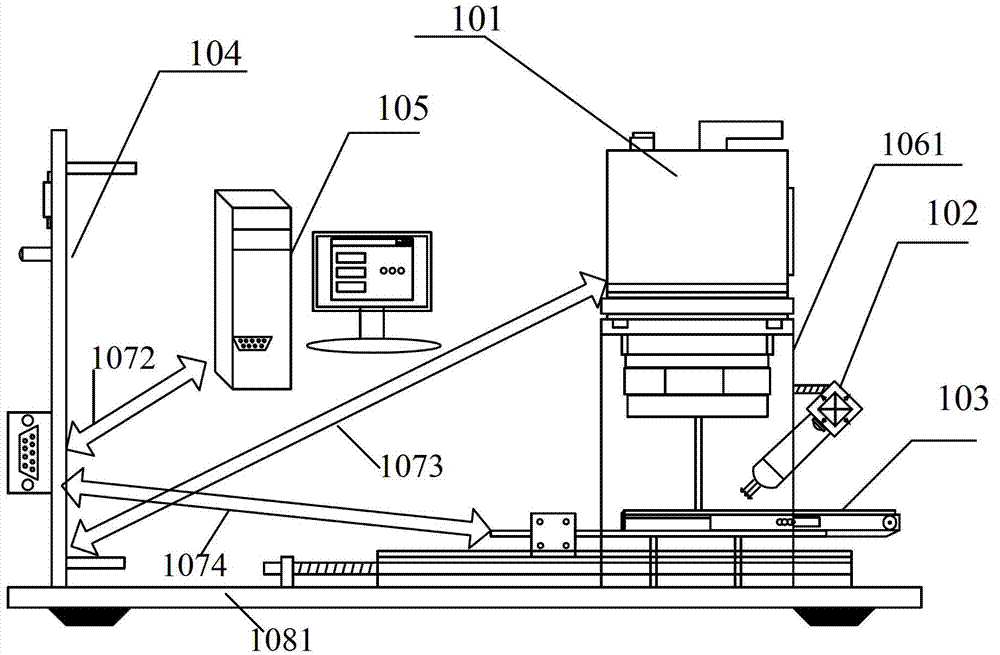

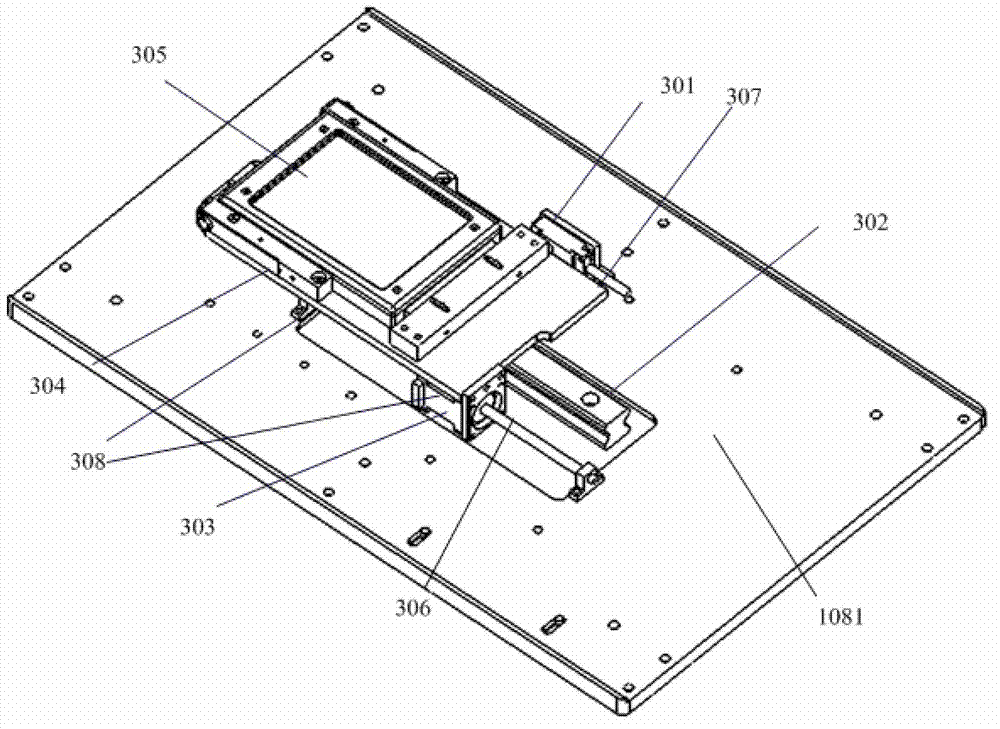

[0030] Such as figure 1 As shown, the filament width measuring device of the present invention includes five parts: an imaging system 101 , an illumination system 102 , a workpiece platform system 103 , a control system 104 and a computer 105 . The lighting system 102 projects the line light source on the filament carrying box 305 of the workpiece platform system 103, and the filament carrying box 305 is driven to reciprocate by the transmission motor 303 on the workpiece platform system 103. At this time, the imaging system 101 collects images with a certain step The shredded leaf image will be merged into a two-dimensional shredded leaf image after scanning. The acquisition of the entire image is completed by the communication between the computer 105 and the control system 104 , and the finally acquired image is calculated by the computer 105 to obtain the result.

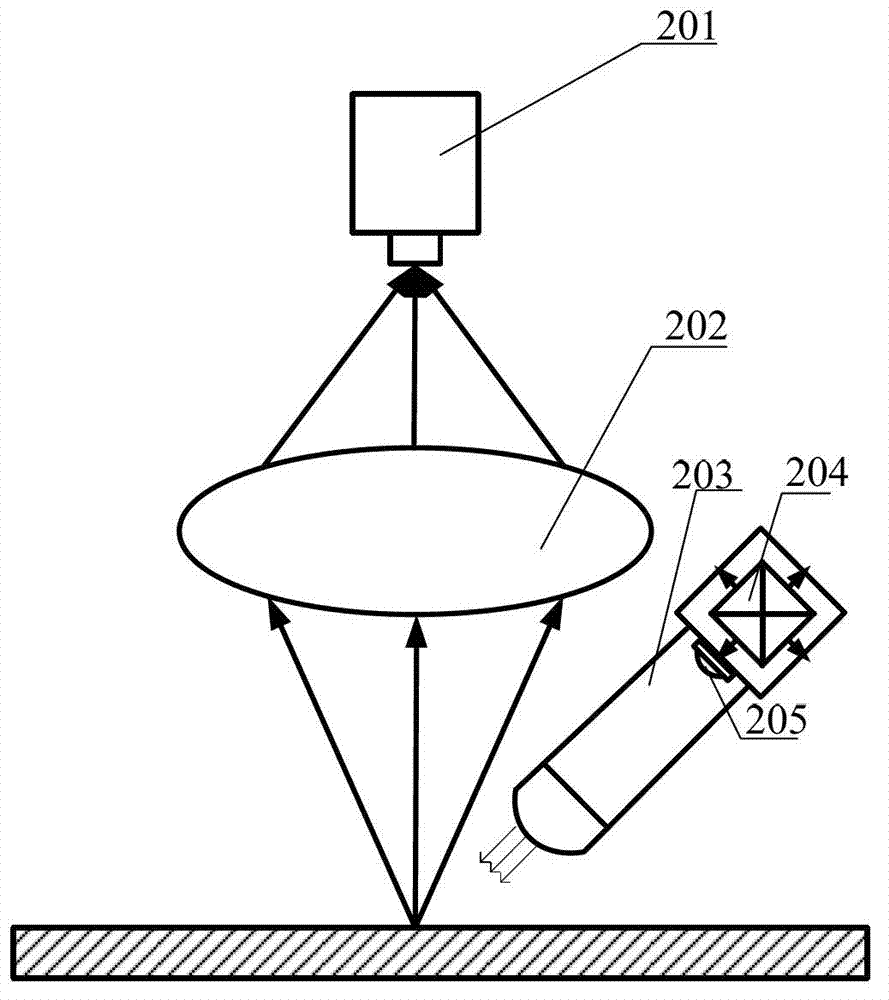

[0031] The imaging system 101 includes a linear array CCD camera 201 and a CCD lens 202; wherein the pixel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com