Leak resistant tamper evident reclosable plastic bag

a plastic bag and leak-proof technology, applied in the field of containers, can solve the problems of bag use (potential contamination) and achieve the effect of reducing the risk of leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

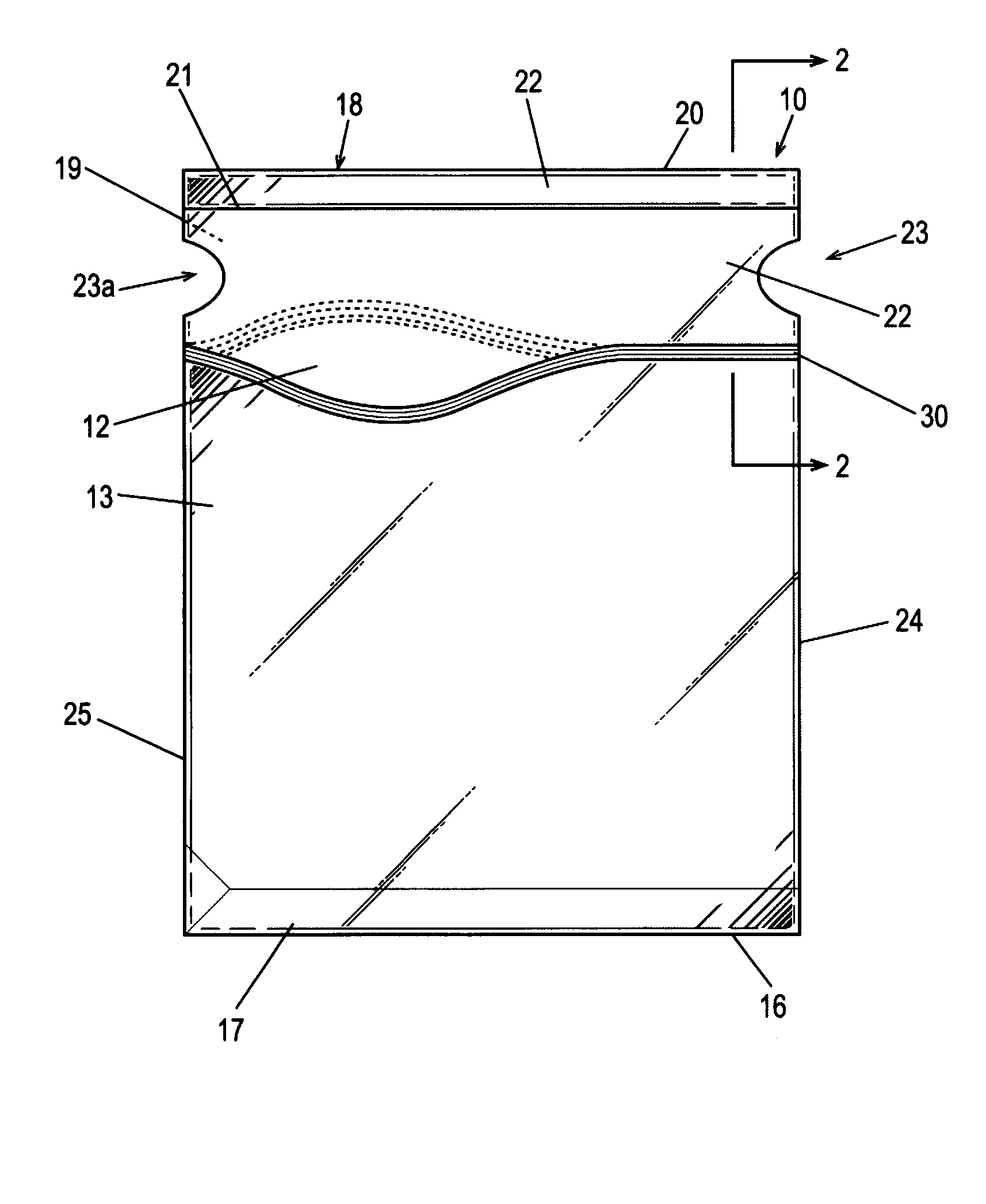

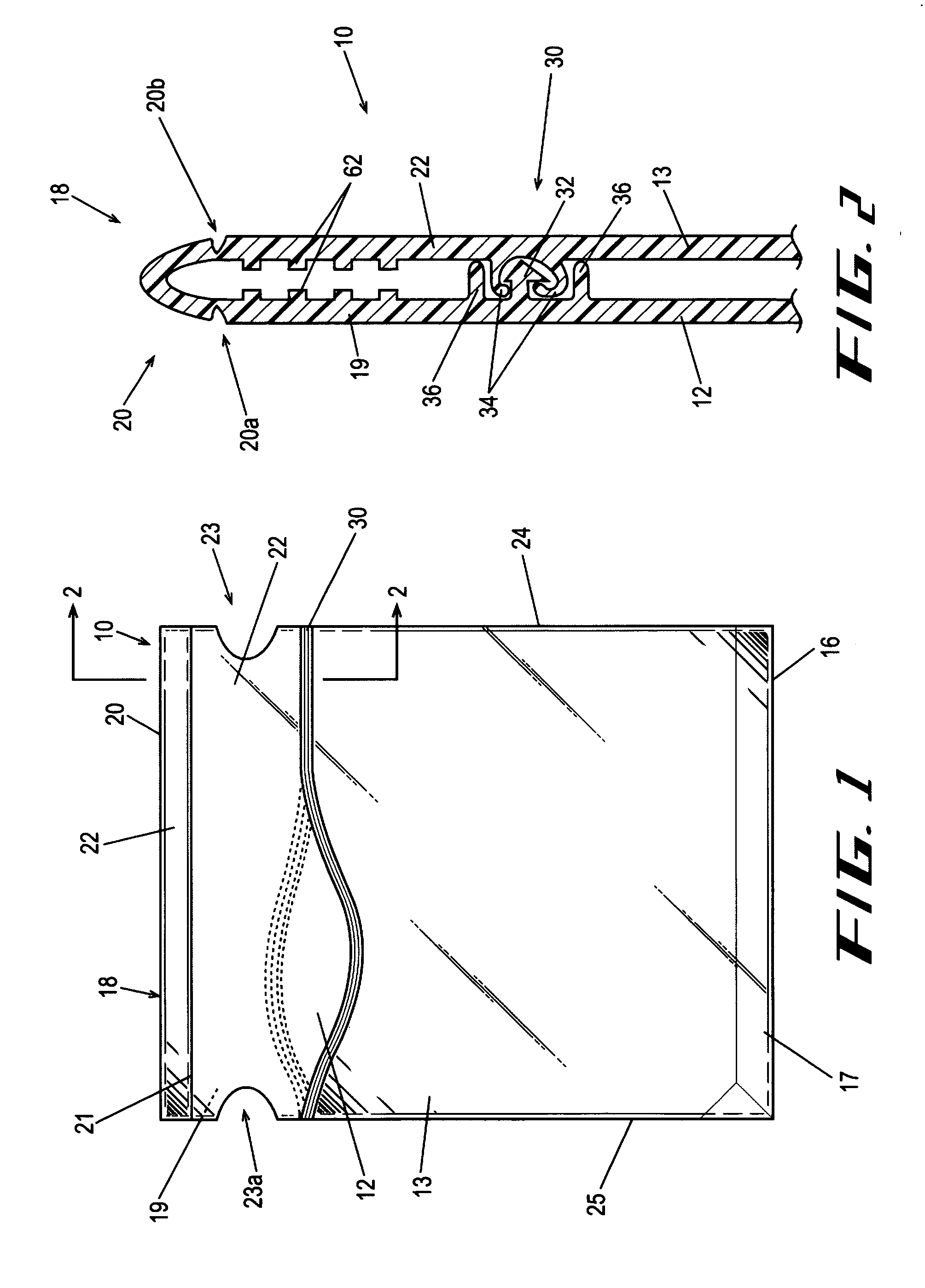

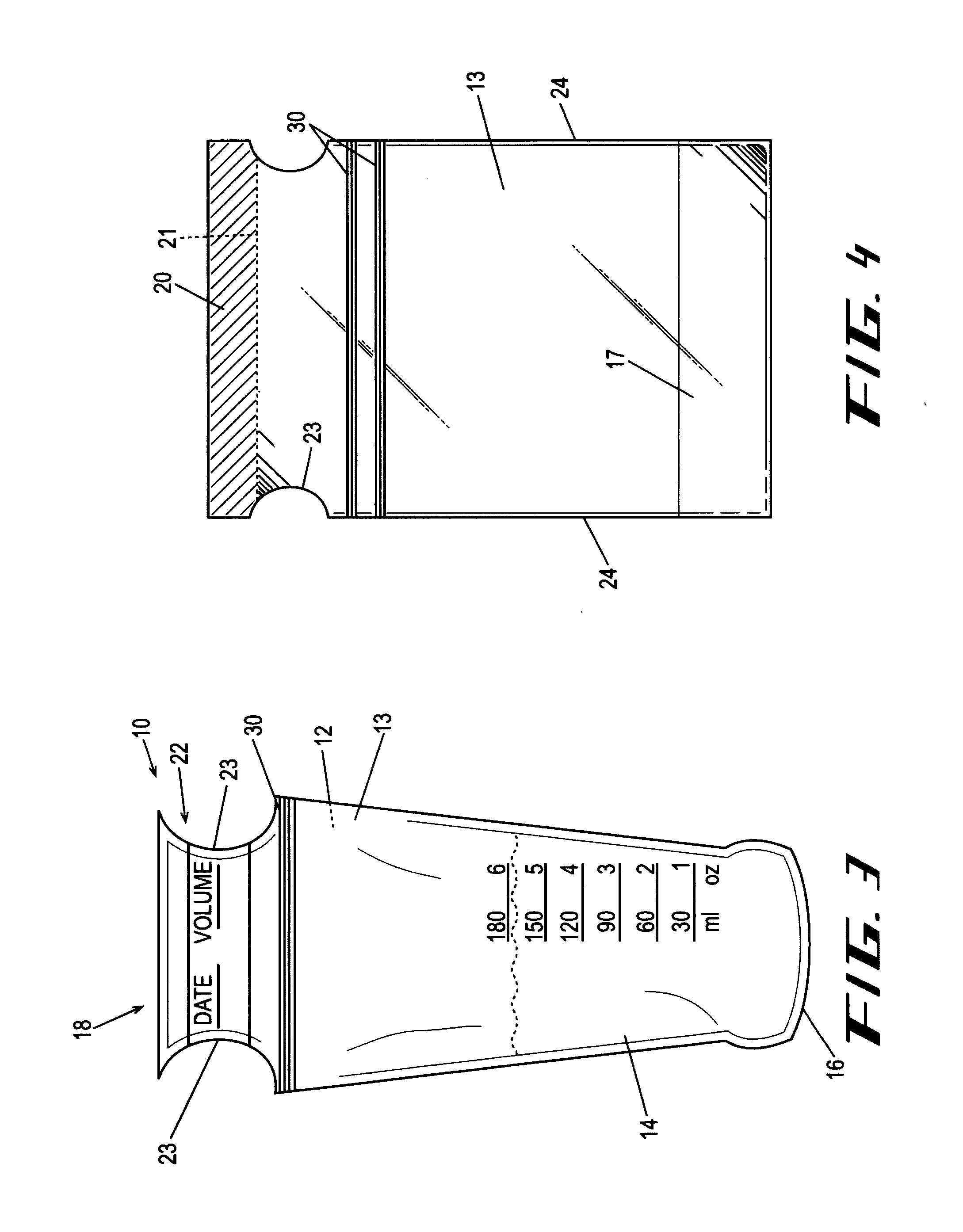

[0025] The present invention is directed to containers and in particular to novel reclosable plastic bags, tamper evident plastic bags, and closure profiles for reclosable bags. The general principles for making reclosable plastic bags are fairly well-known and are typified in numerous prior patents. Various developments in the reclosable plastic bag art, including methods of manufacture and various die assemblies used to manufacture such bags, are disclosed in U.S. Pat. No. 6,217,216 to Taheri (describes methods for forming bags), U.S. Pat. No. 4,755,248 to Geiser et al. (die assemblies), U.S. Pat. Nos. 4,101,355 (using adhesives to join a closure profile to a bag) and 3,338,284 (forming a bag film web using a single extrusion operation) to Ausnit, U.S. Pat. Nos. Re. 28,959, 29,208 and 28,969 to Naito, U.S. Pat. No. Re. 33,674 to Uramoto, and U.S. Pat. No. Re. 26,991 to Luca, (interlocking closure profiles), all of which are hereby incorporated by reference in their entireties for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com