Heater assembly for washing machine

a technology for heaters and washing machines, applied in the field of washing machines, can solve the problems of affecting the service life of the heater, and requiring a lot of time, so as to improve the stability/reliability and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. In describing the embodiments of the present invention, same parts will be given the same names and reference symbols, and iterative description of which will be omitted.

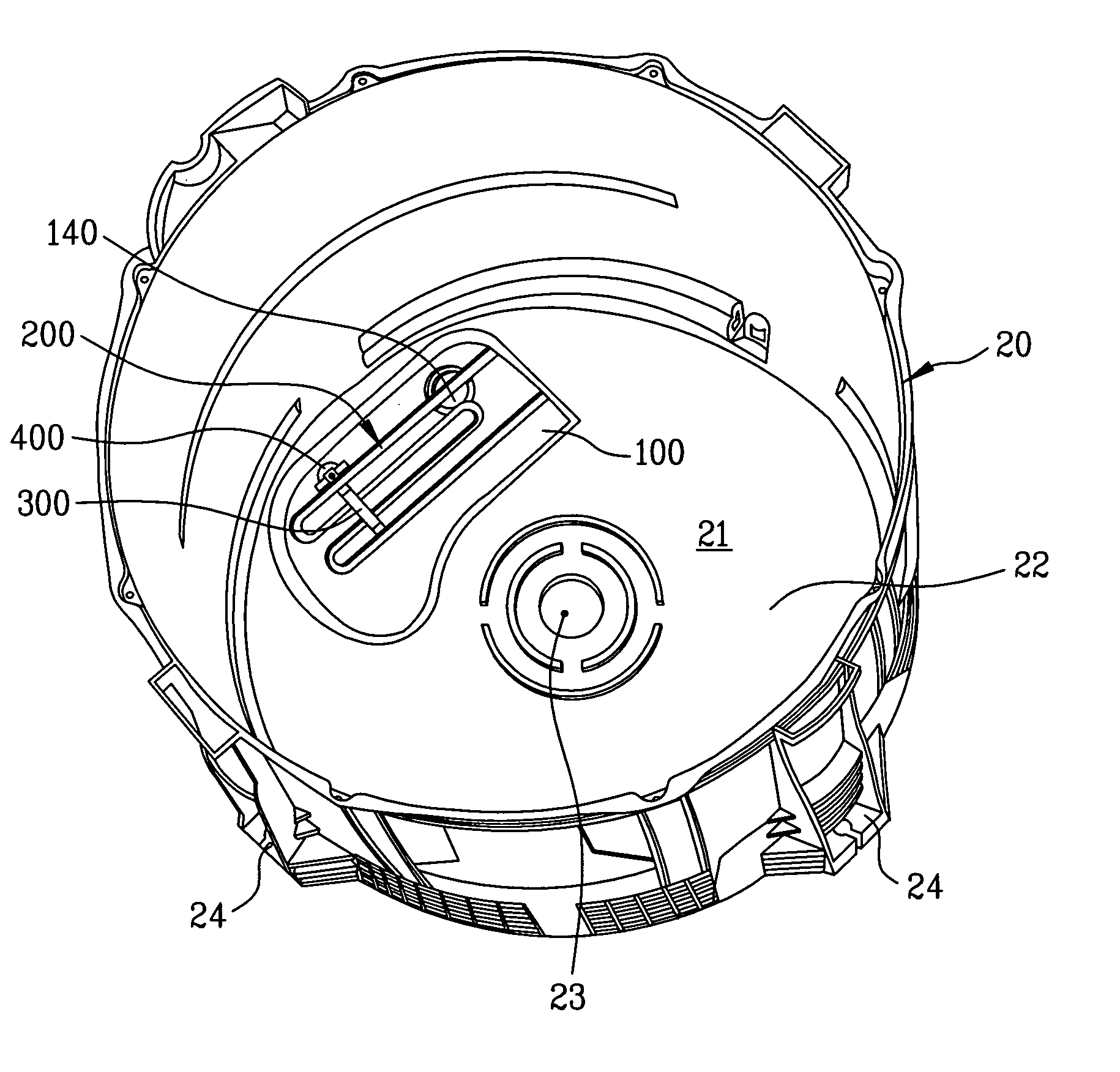

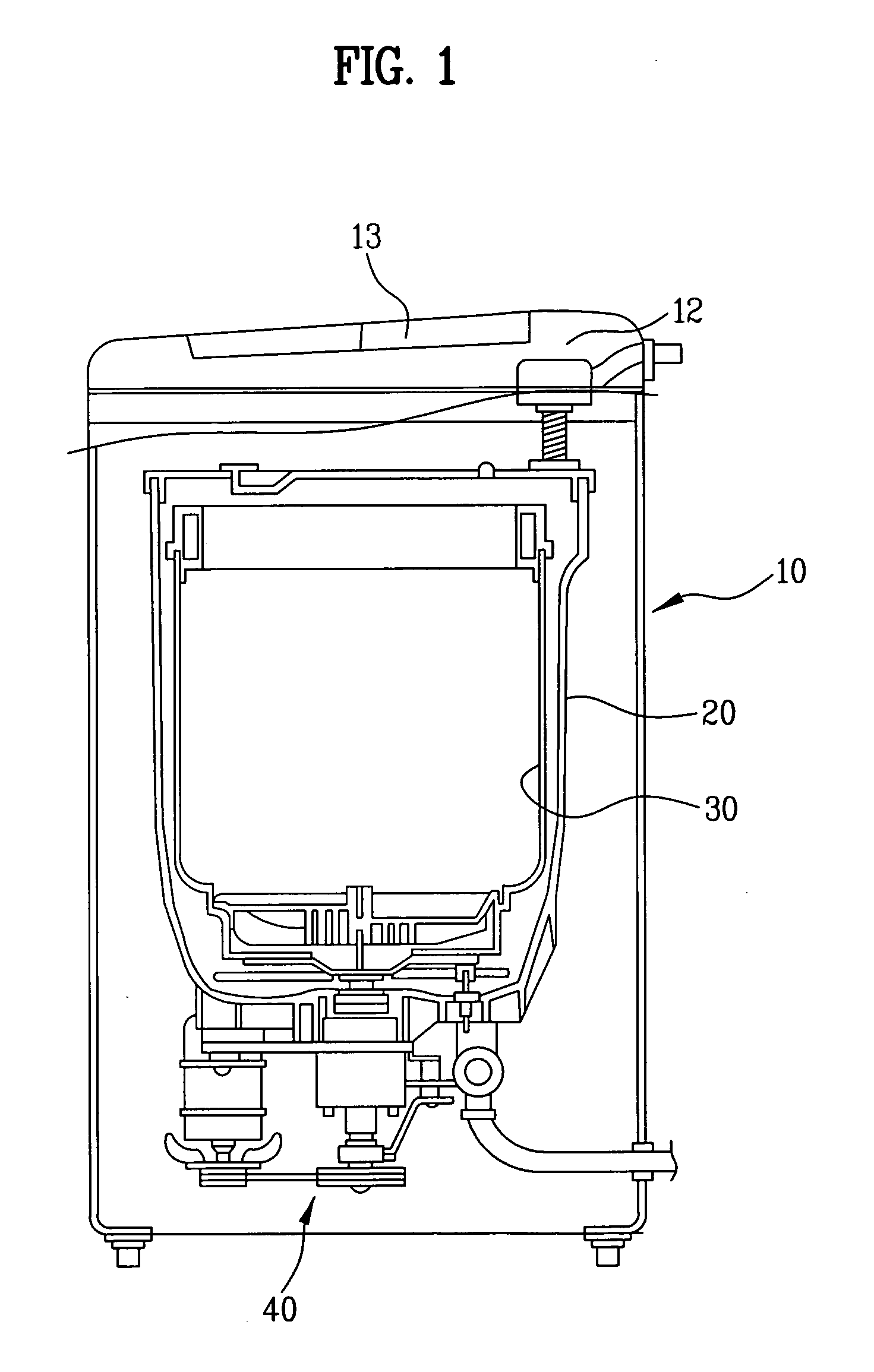

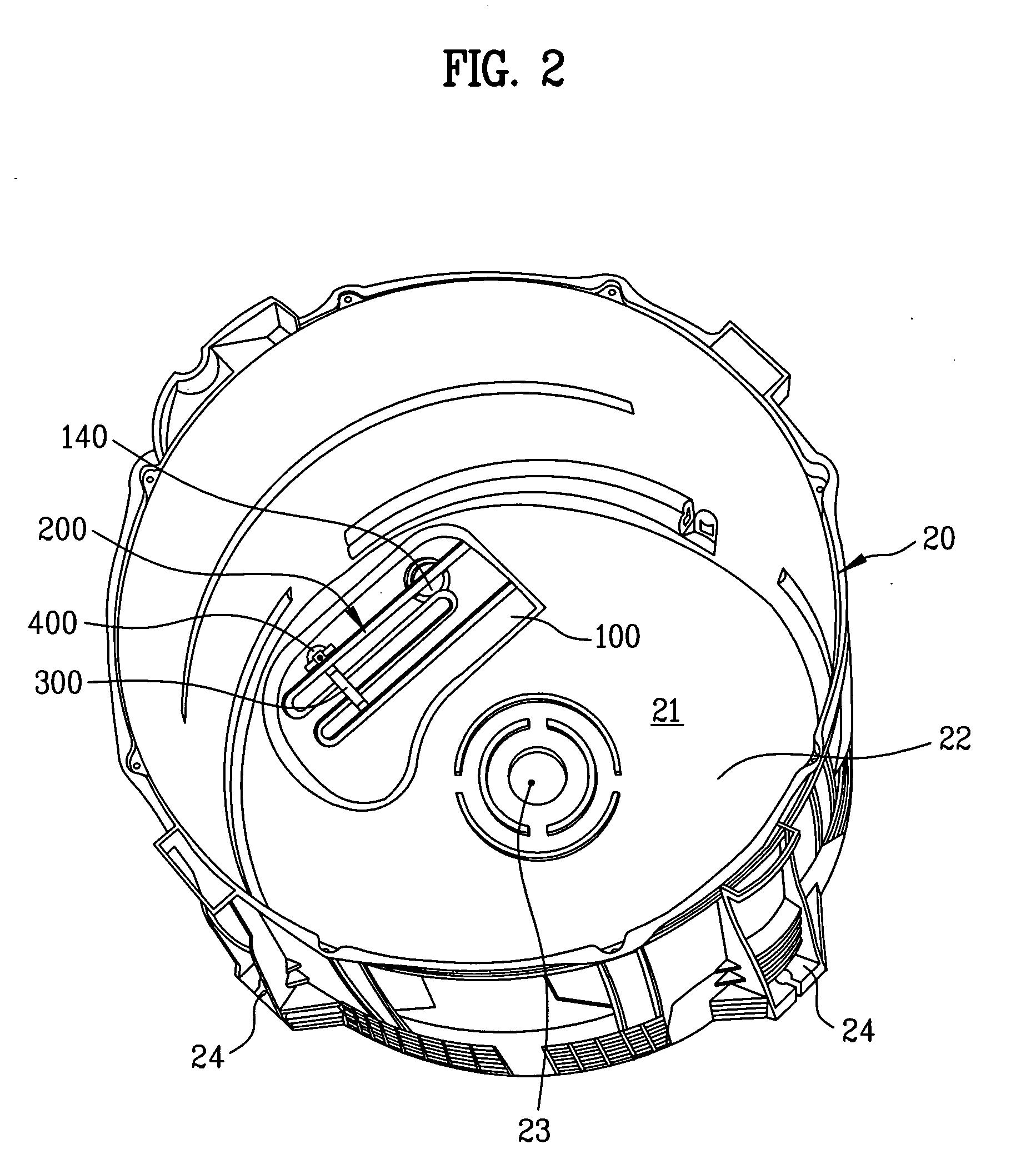

[0031]FIG. 1 is a sectional view showing a washing machine according to the present invention, and FIG. 2 is a perspective view showing a heater assembly according to the present invention together with an outer tub.

[0032] Referring to FIG. 1, the washing machine of the present invention comprises a housing 10, and an outer tub 20 and an inner tub 30 both installed inside the housing 10.

[0033] The housing 10 is configured to hold various components of the washing machine therein and to protect such components. The housing 10 includes a top cover 12 provided at a top portion of the washing machine and a door 13 provided at the top cover 2. The top cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com