In-line roller skate with internal support and external ankle cuff

a technology of internal support and external support, which is applied in the direction of ski bindings, footwear, skiing, etc., can solve the problems of difficult sideward or lateral balance, difficult to flex forward and rearward, hot, uncomfortable, etc., and achieve superior lateral and medial support and great aesthetic appeal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

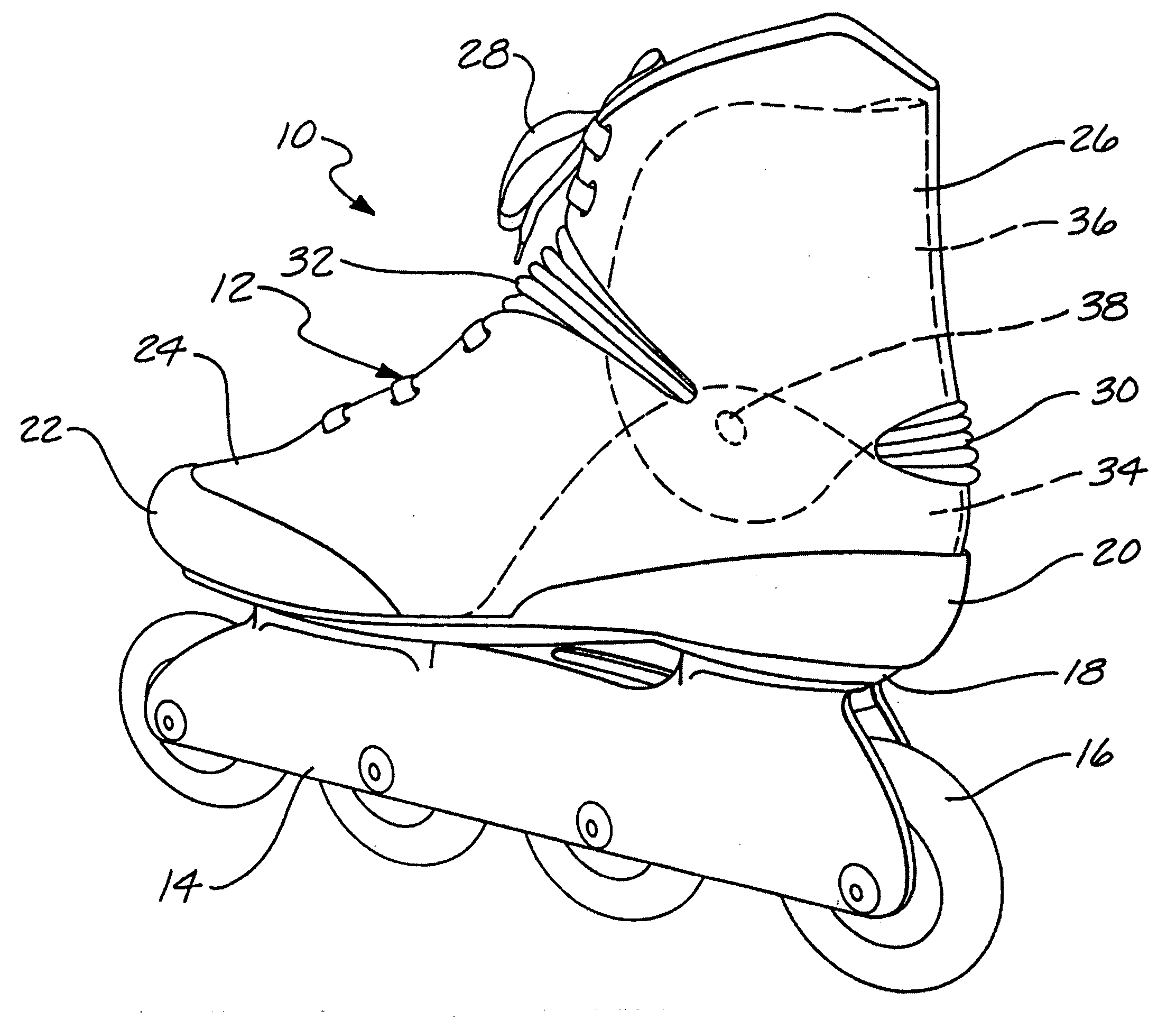

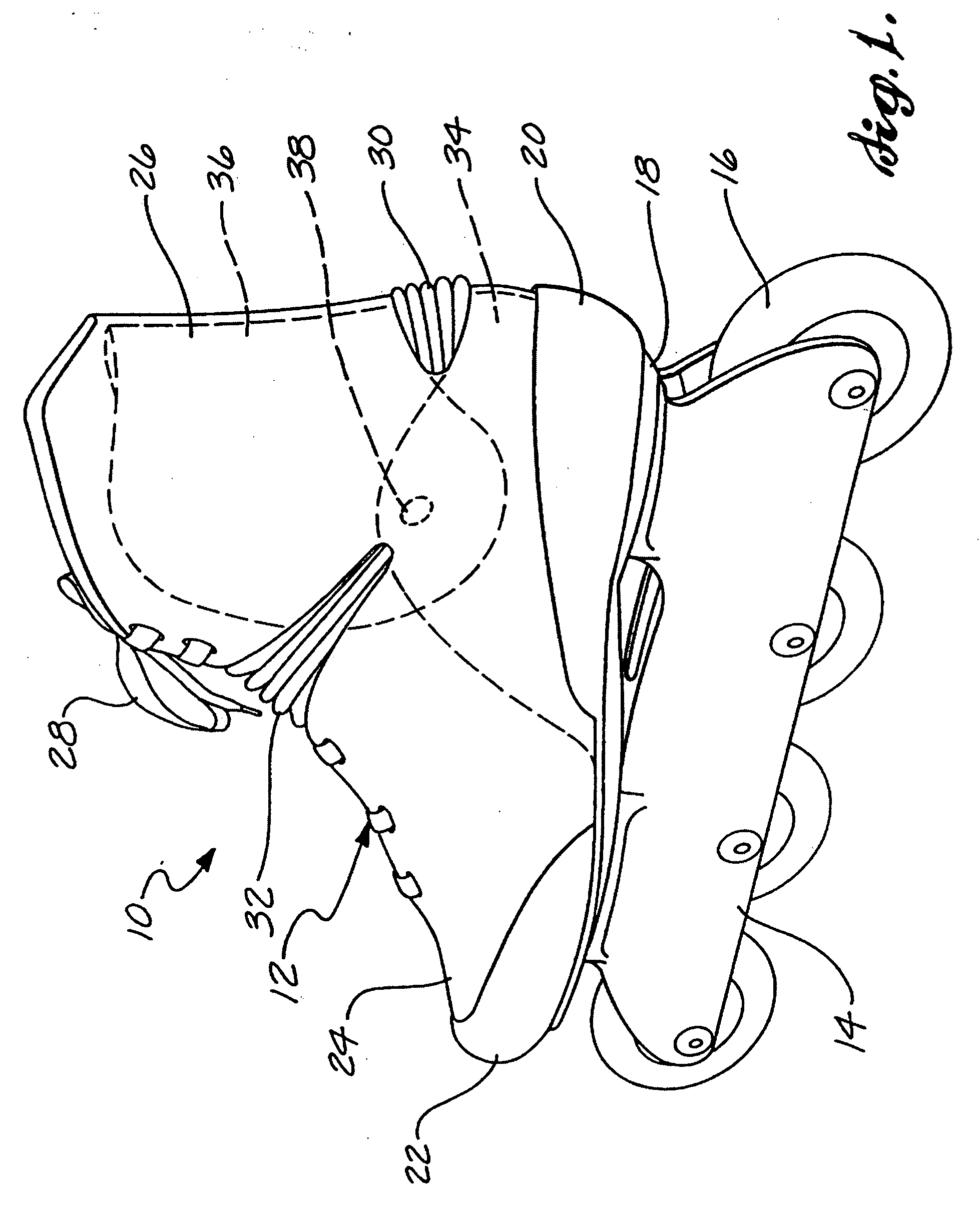

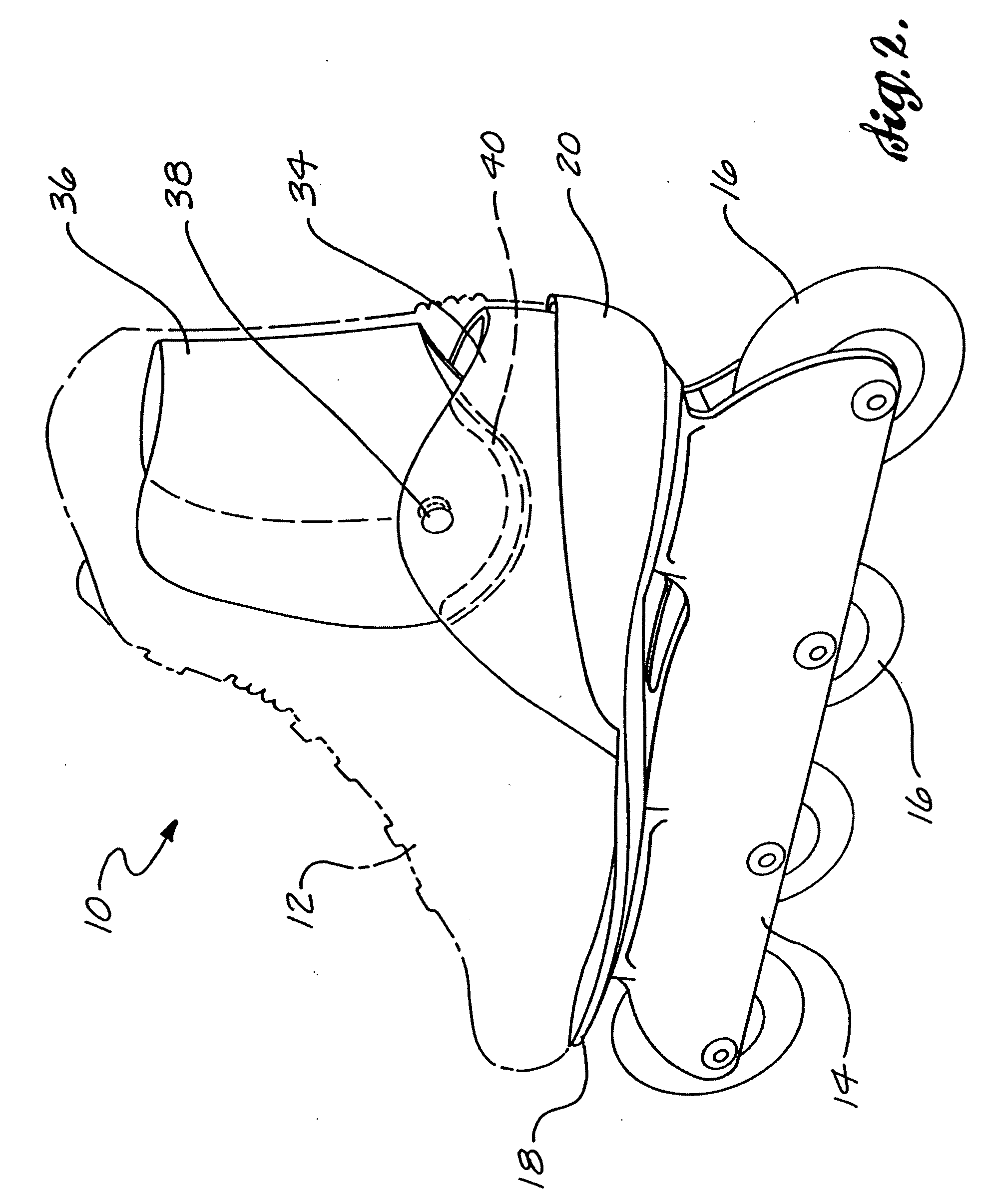

[0042] Referring to FIG. 1, an in-line roller skate 10 made according to the present invention is disclosed. In-line skate 10 includes an upper 12 connected to a frame 14 that secures wheels 16. Upper 12 includes a rigid base 18 for interconnection to frame 14. Preferably, rigid base 18 extends beneath upper 12 substantially from heel to toe. An external heel counter 20 is preferably integrally formed with base 18. Alternatively, external heel counter 20 could be omitted or formed separately, unattached to base 18. A toe cap 22 is also separately formed and attached to base 18 to protect the toe end of the skate from scuffs and wear. A toe cap 22 also protects the skater's foot from impacts with hard surfaces.

[0043] Most of the rest of upper 12 is constructed of soft, breathable, pliable material of the type commonly used in shoes or hiking boots. Thus, synthetic or natural leathers and meshes or other fabrics may be used to construct the soft portions of upper 12. These portions i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com