Multi-hedral rotary wing

a rotary wing and multi-hedral technology, applied in the field of aerodynamic structures, can solve the problems of increasing the stress in the blade structure, reducing the degree of anhedral, and affecting the performance of the forward flight performance of the rotor blade, so as to reduce the influence of the tip vortex, improve the hover performance, and improve the effect of hover performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

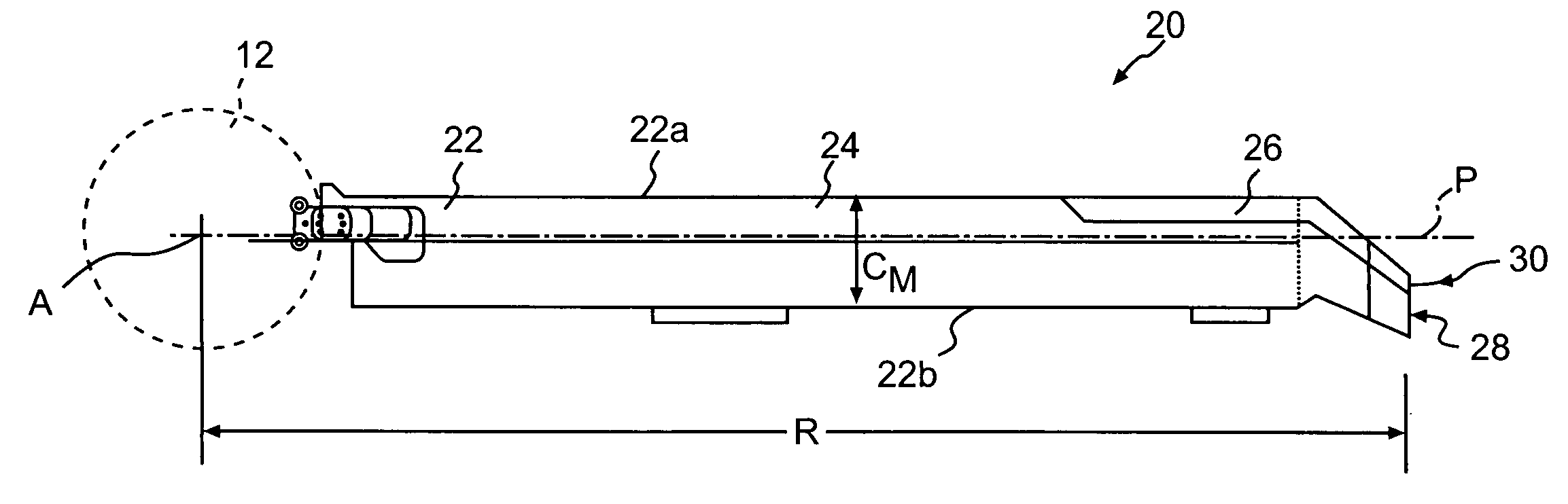

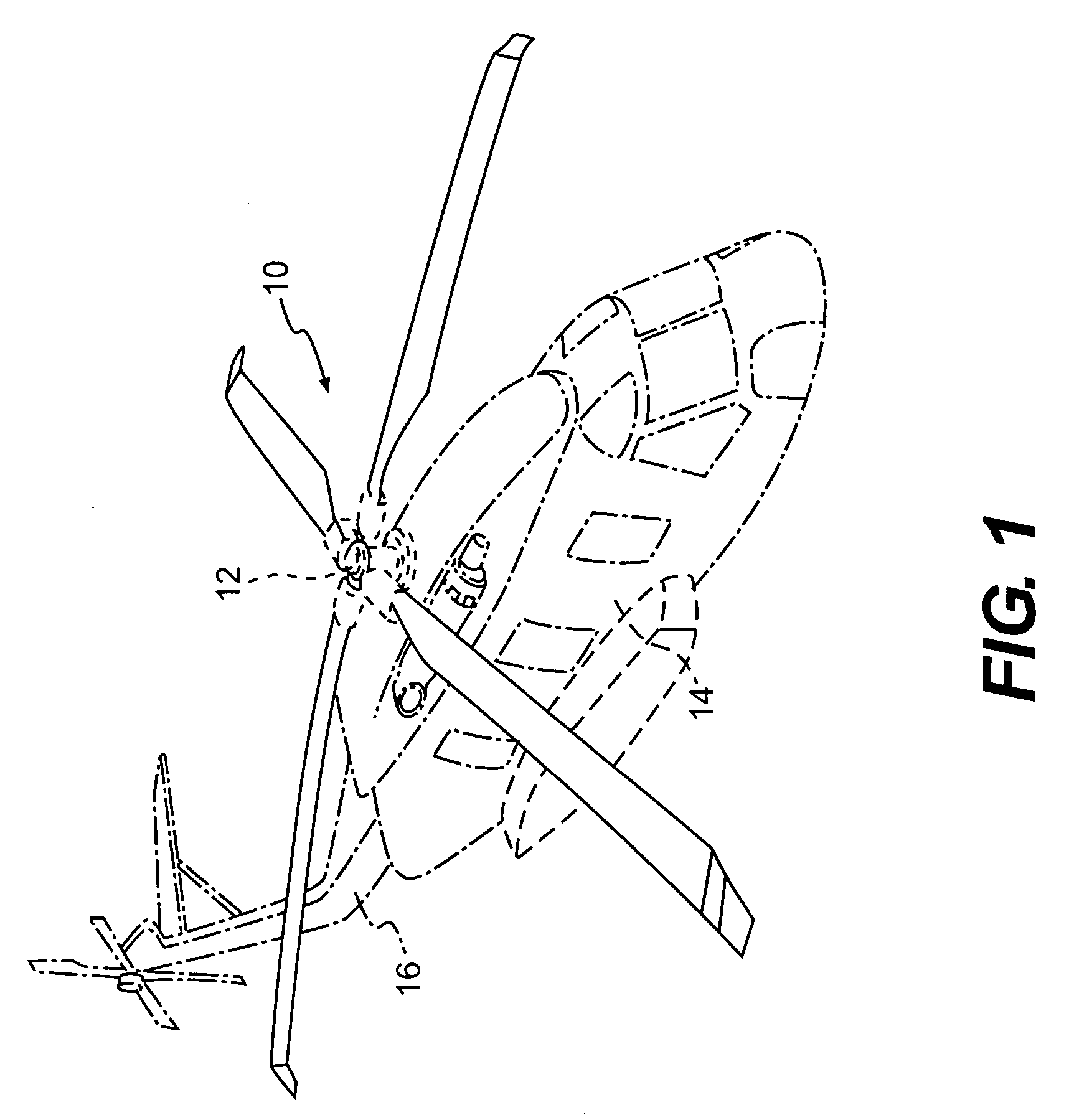

[0020]FIG. 1 schematically illustrates a rotary-wing aircraft 10 having a main rotor assembly 12. The aircraft 10 includes an airframe 14 having an extending tail 16 which mounts an anti-torque rotor 18. Although a particular helicopter configuration is illustrated in the disclosed embodiment, other machines such as turbo-props, tilt-rotor and tilt-wing aircraft will also benefit from the present invention.

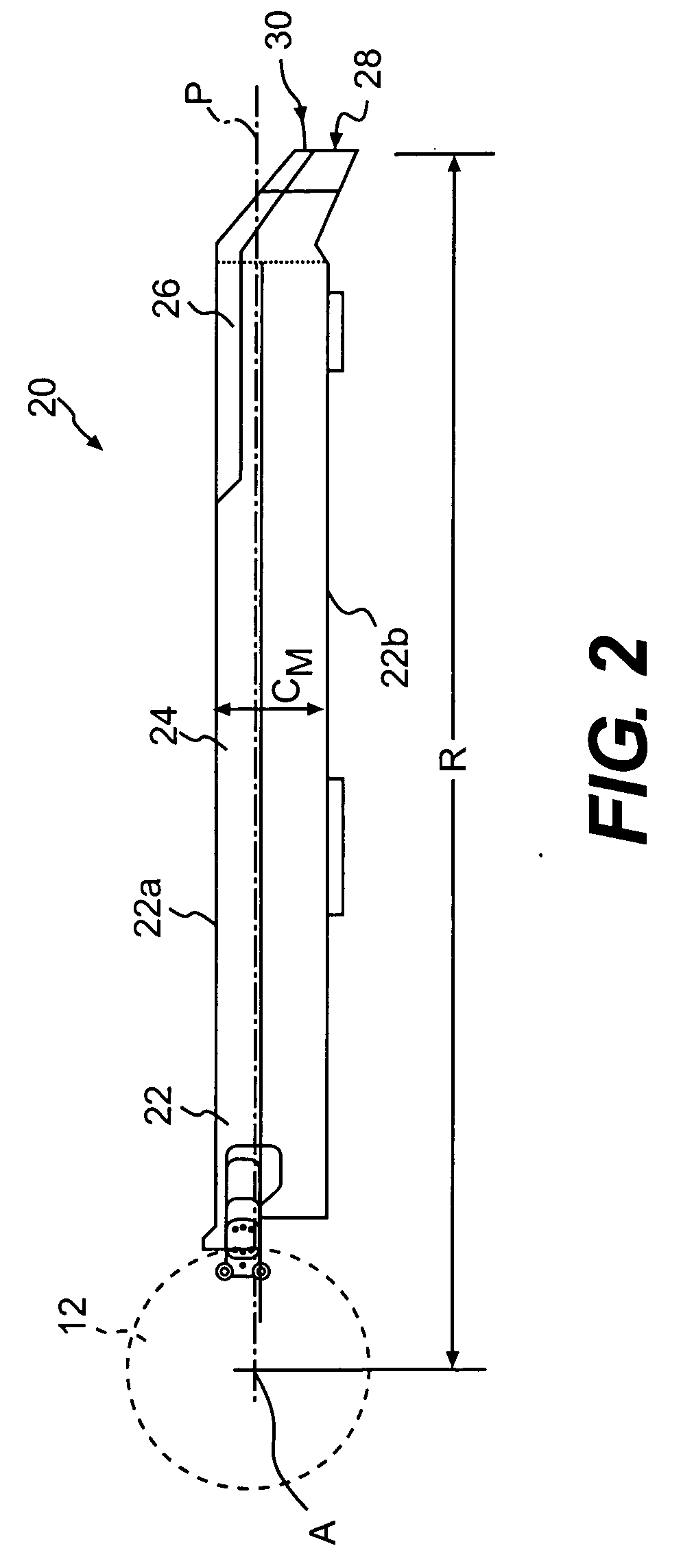

[0021] Referring to FIG. 2, a rotor blade 20 (only one illustrated) of the rotor assembly 12 includes an inboard section 22, an intermediate section 24, and an outboard section 26. The inboard, intermediate, and outboard sections 22, 24, 26 define the span of the main rotor blade 20. The rotor blade sections 22, 24, 26 define a blade radius R between the axis of rotation A and a distal end 30 of a blade tip section 28.

[0022] The blade root portion 22 is attached to the rotor assembly 12 for rotating the rotor blade 20 about the axis of rotation A and for pitching about a longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com