Side plate with reduced warp for heat exchanger and heat exchanger using the same

a technology of side plate and heat exchanger, which is applied in the direction of indirect heat exchanger, lighting and heating apparatus, stationary conduit assembly, etc., can solve the problems of unbalanced material stress state, side plate brought into unbalanced stress state, and it is difficult to assemble the end of the side plate in the lengthwise direction, and achieves the effect of simple pressing form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

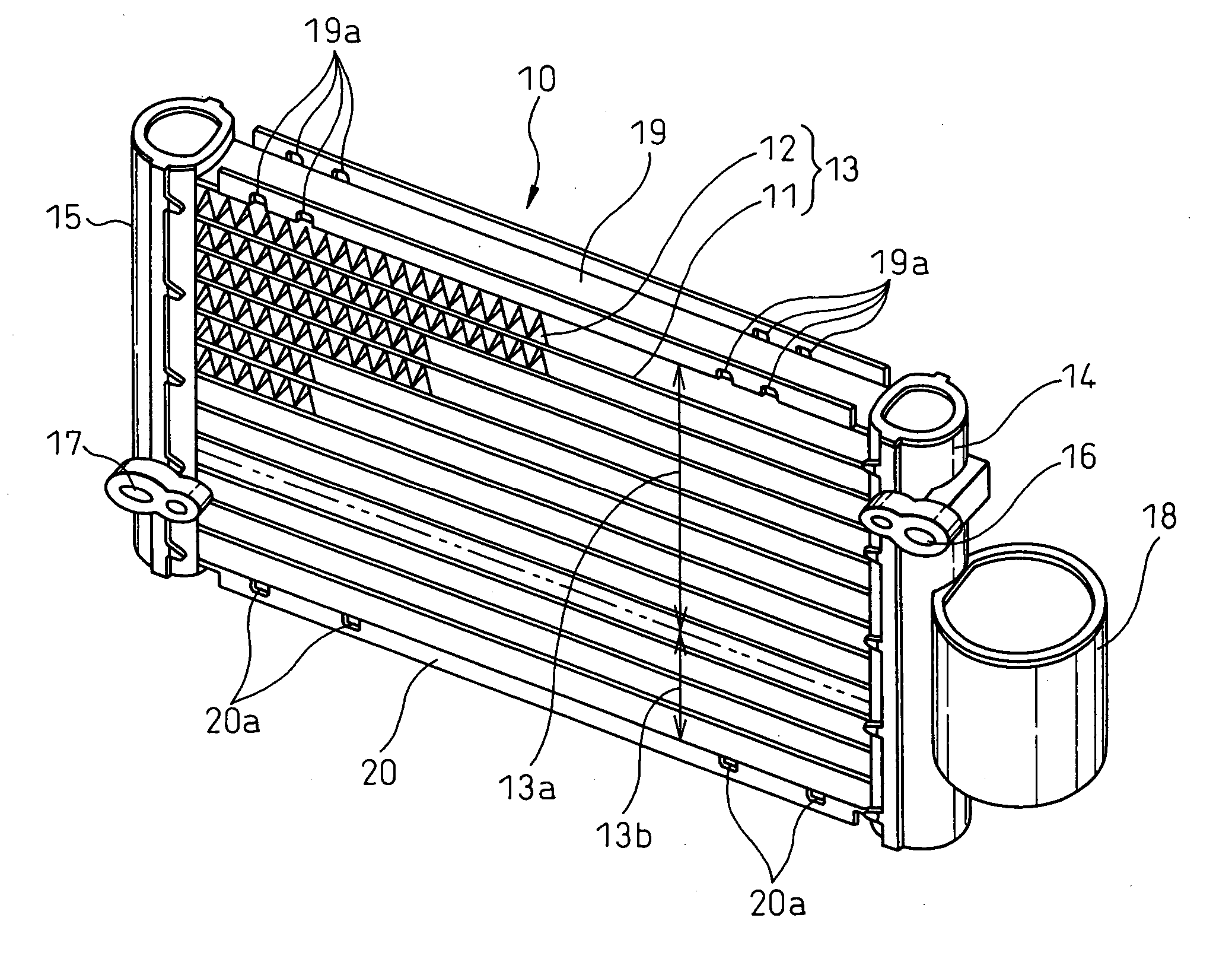

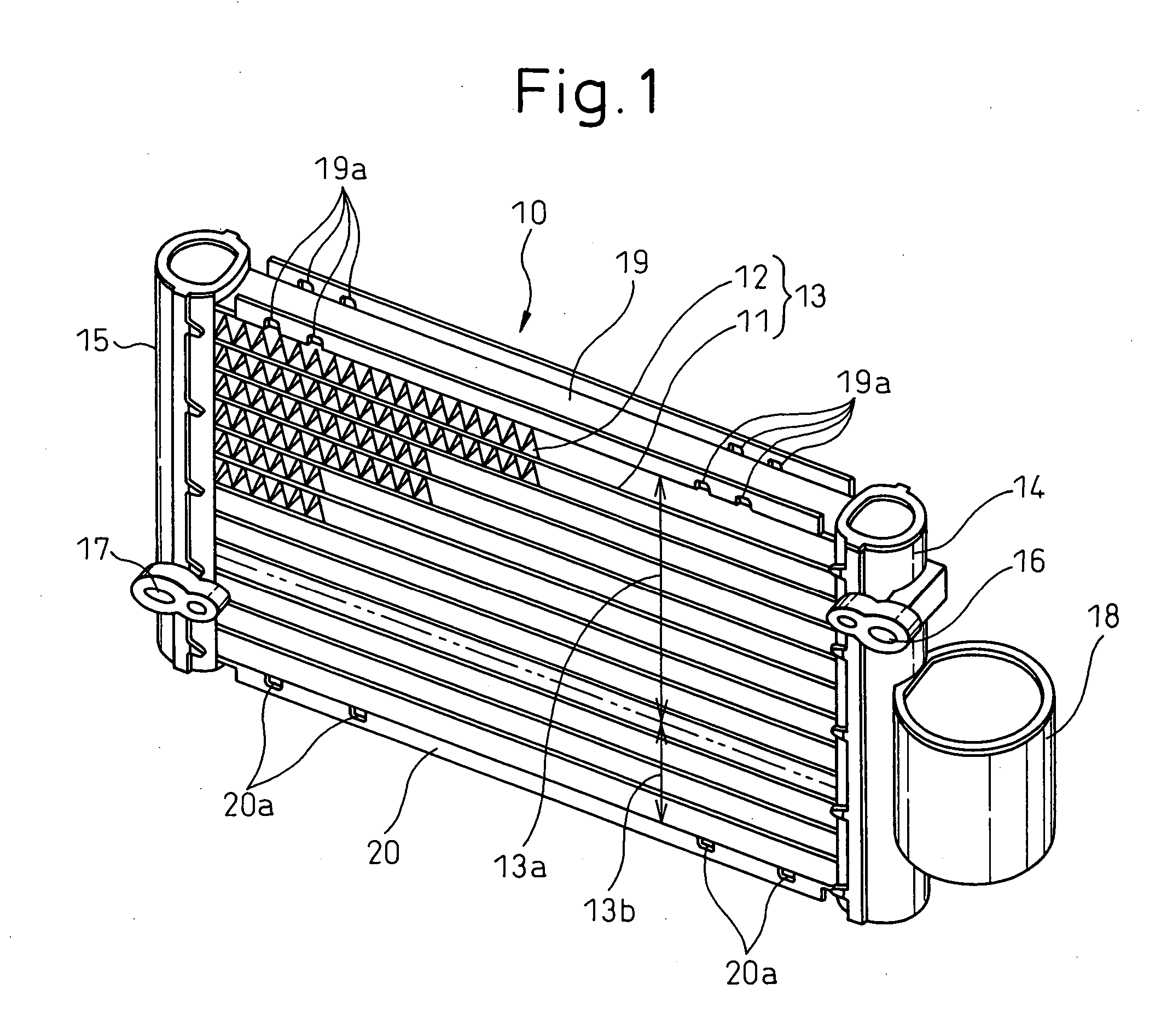

[0037] The present embodiment relates to a condenser for vehicle air conditioning and, first of all, an outline of the condenser for vehicle air conditioning is explained by referring to FIG. 1. As is widely known, a condenser 10 is connected to the discharge side of a refrigerant of a compressor in a refrigerating cycle and cools and condenses the gas refrigerant discharged from the compressor with the outside air.

[0038] The condenser 10 has a core section 13 comprising a plurality of flat tubes 11 extending in the horizontal direction and a plurality of corrugated fins 12, and on both the right end and the left end of the core section 13, header tanks 14 and 15 having a substantially cylindrical shape and extending in the vertical direction are arranged, and both ends of the flat tubes 11 are communicated with the inside of the header tanks 14 and 15.

[0039] At the upper part of the header tank 14 on one side, an inlet join 16 through which a discharged gas refrigerant, from a co...

second embodiment

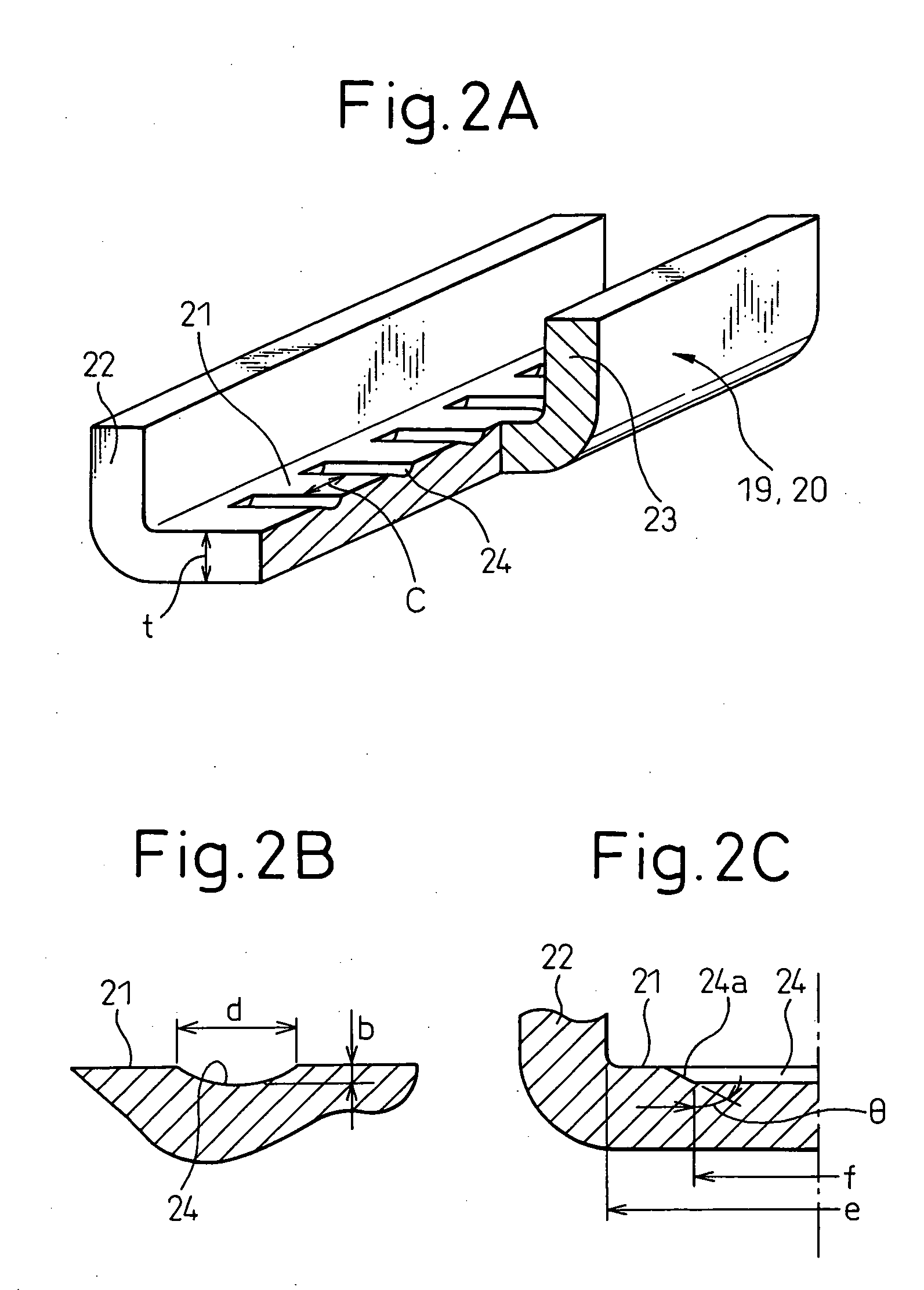

[0063] Although the recesses 24 are formed on the inner surface of the bottom section 21 of the side plates 19 and 20 having a U shaped section in the first embodiment, the recesses 24 are formed on the outer surface of the bottom section 21 in the second embodiment as shown in FIG. 4.

[0064] It has been confirmed that even if the recesses 24 are formed on the outer surface of the bottom section 21 as described above, the warp a can be reduced as in the first embodiment.

[0065] However, as is seen from FIG. 1, the corrugated fin 12 is joined by brazing to the outer surface of the bottom section 21 of the side plates 19 and 20 and, therefore, the formation of the recesses 24 on the outer surface deteriorates the joinability (brazing properties) between the side plates 19 and 20 and the corrugated fin 12. Therefore, from the viewpoint of the joinability, the first embodiment is preferable to the second embodiment.

Other Embodiments

[0066] In the above mentioned embodiments, although t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap