Upper frame for a vertical venetian blind

a vertical venetian blind and upper frame technology, applied in the field of upper frame for vertical venetian blinds, can solve the problems of occupying a lot of space and costing a lot and achieve the effects of less space, practical value in the industry, and low cost in packing, storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

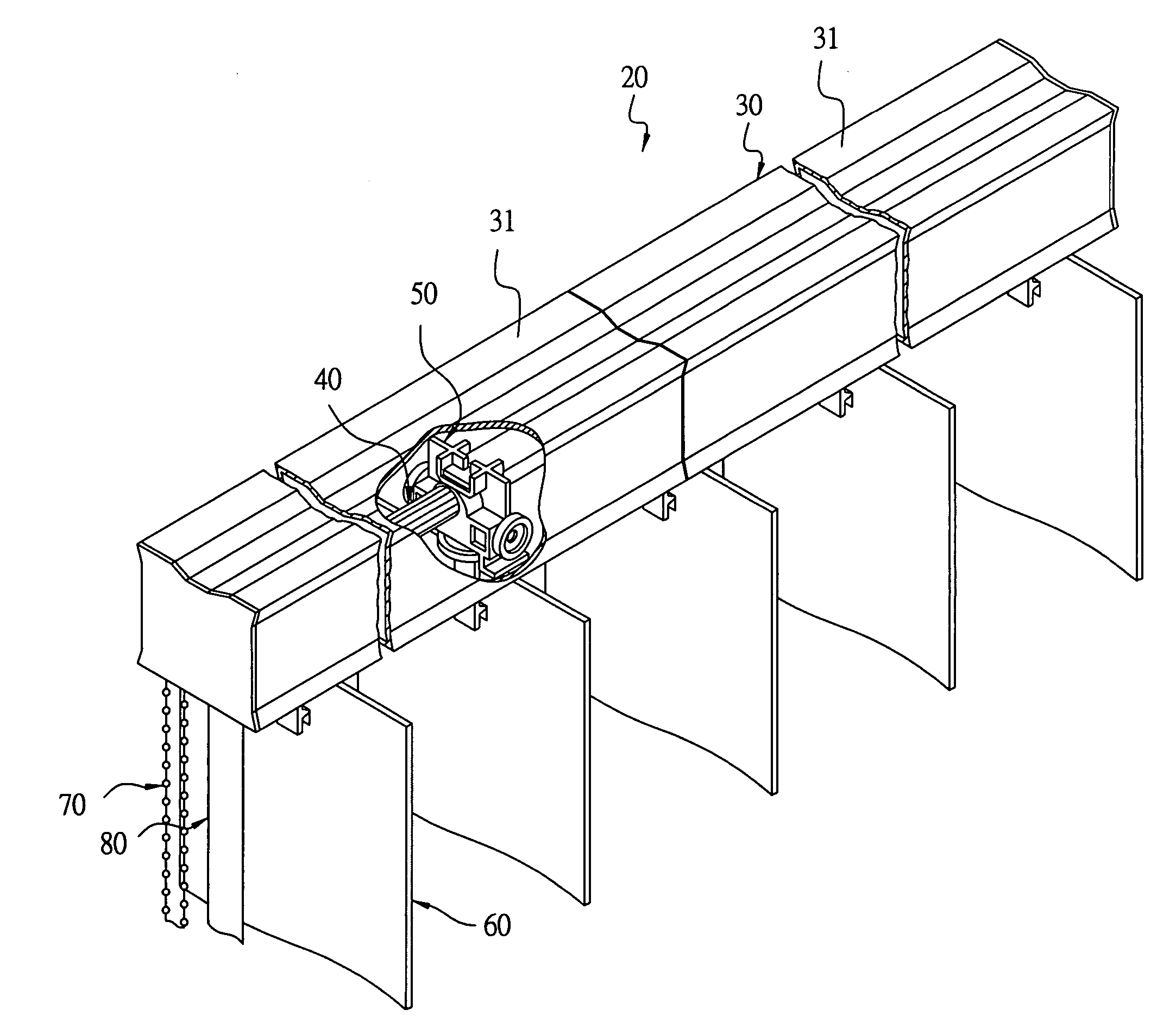

[0019] A first preferred embodiment of an upper frame 20 for a vertical Venetian blind in the present invention, as shown in FIG. 2, includes a horizontal rod 30 of an inverted U-shape and a slide rail 40 as main components combined together. The slide rail 40 is positioned inside the horizontal rod 30 and provided thereon with plural slide blocks 50 preset in number respectively for connecting a screen 60. The horizontal rod 30 is provided with a control cord 70 and a control rod 80 at one end for respectively controlling the screens 60 to be expand, collapse or deflect.

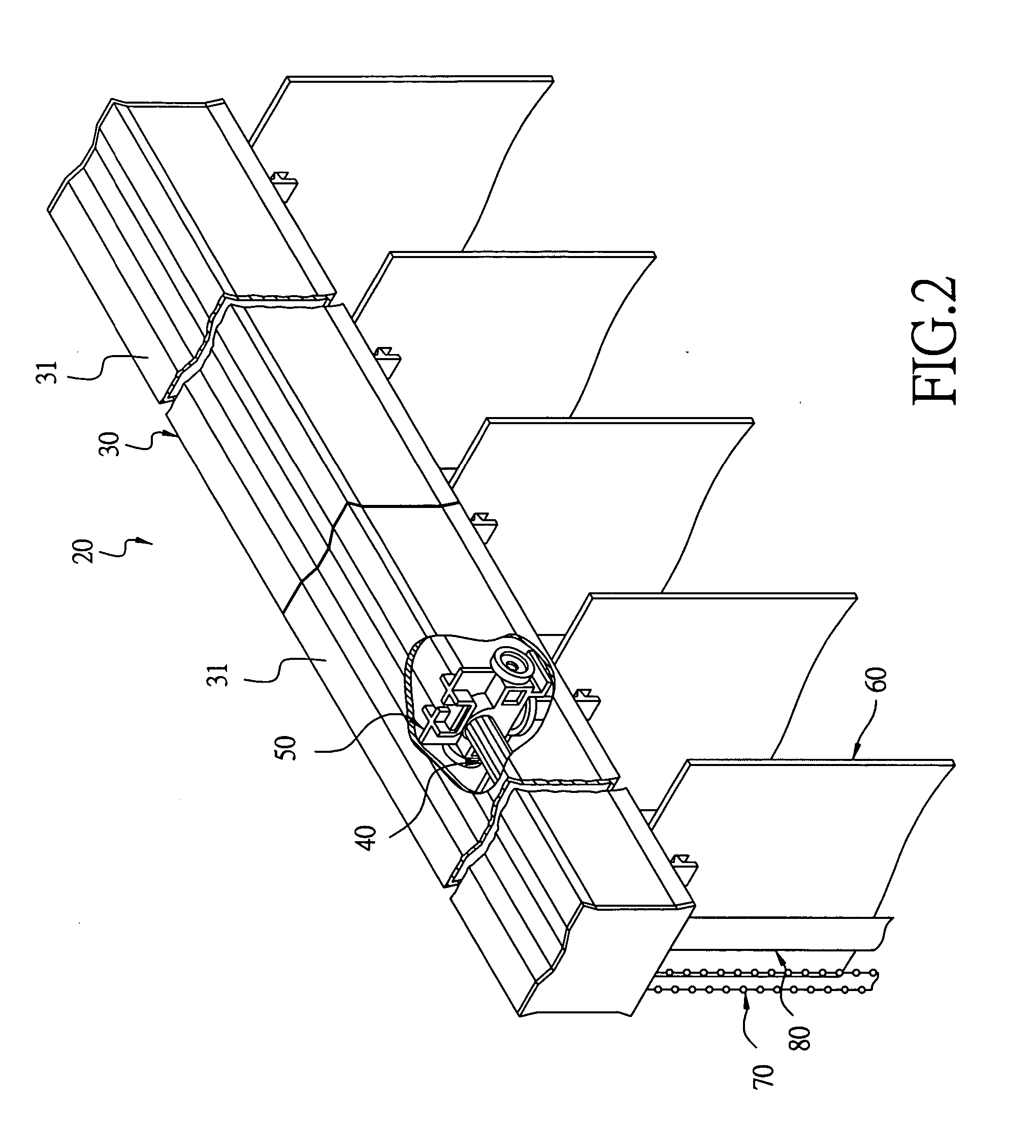

[0020] The horizontal rod 30, as shown in FIGS. 3 and 4, consists axially of two rod portions 31. One of the two rod portions 31 has one of two connecting ends formed with two insert grooves 311, while the other of the two rod portions 31 has one of two connecting ends formed with two projections 312 matching with the two insert grooves 311. The two rod portions 31 can easily be connected together to make up the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com