Nail file and shine block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

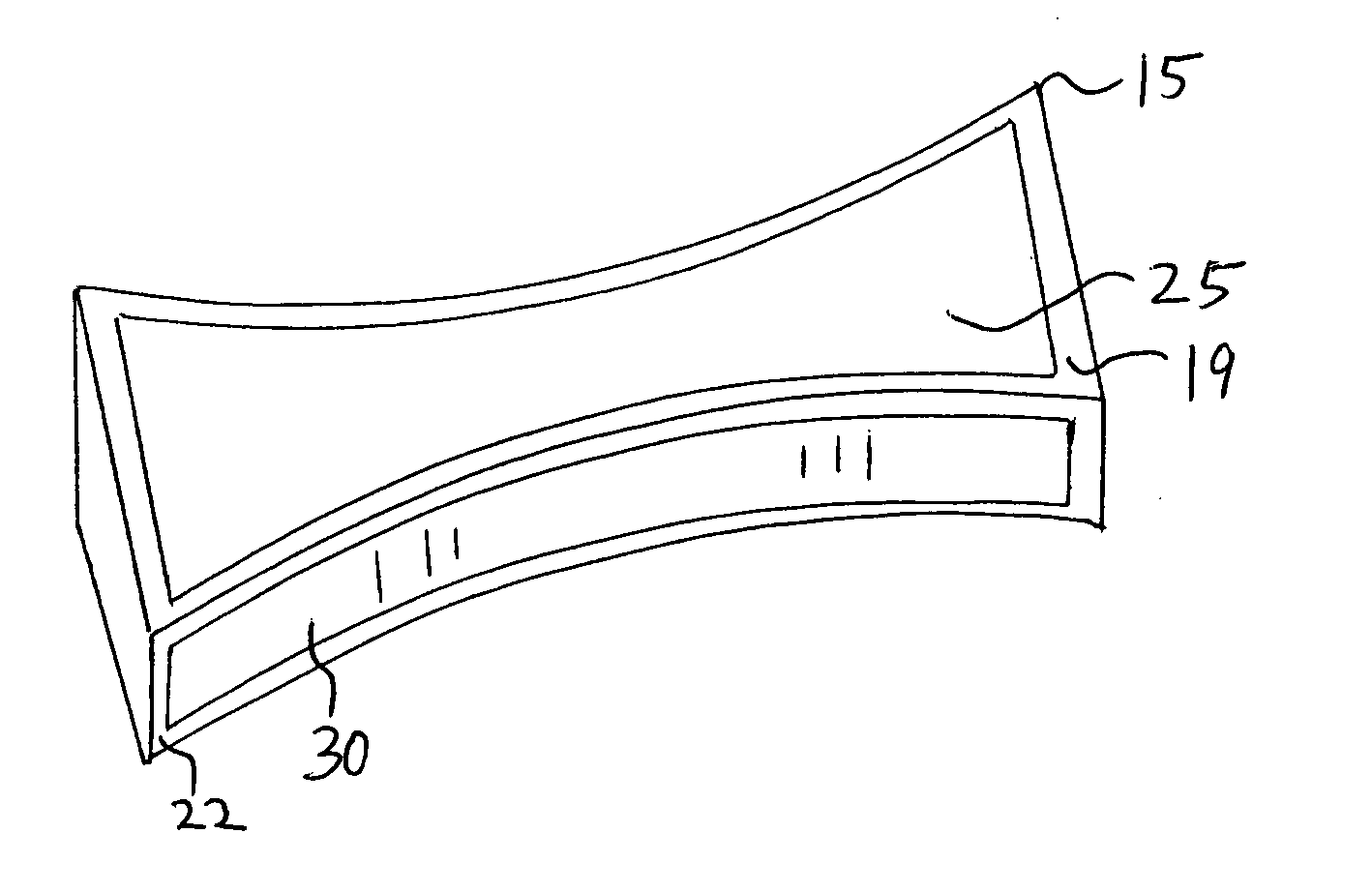

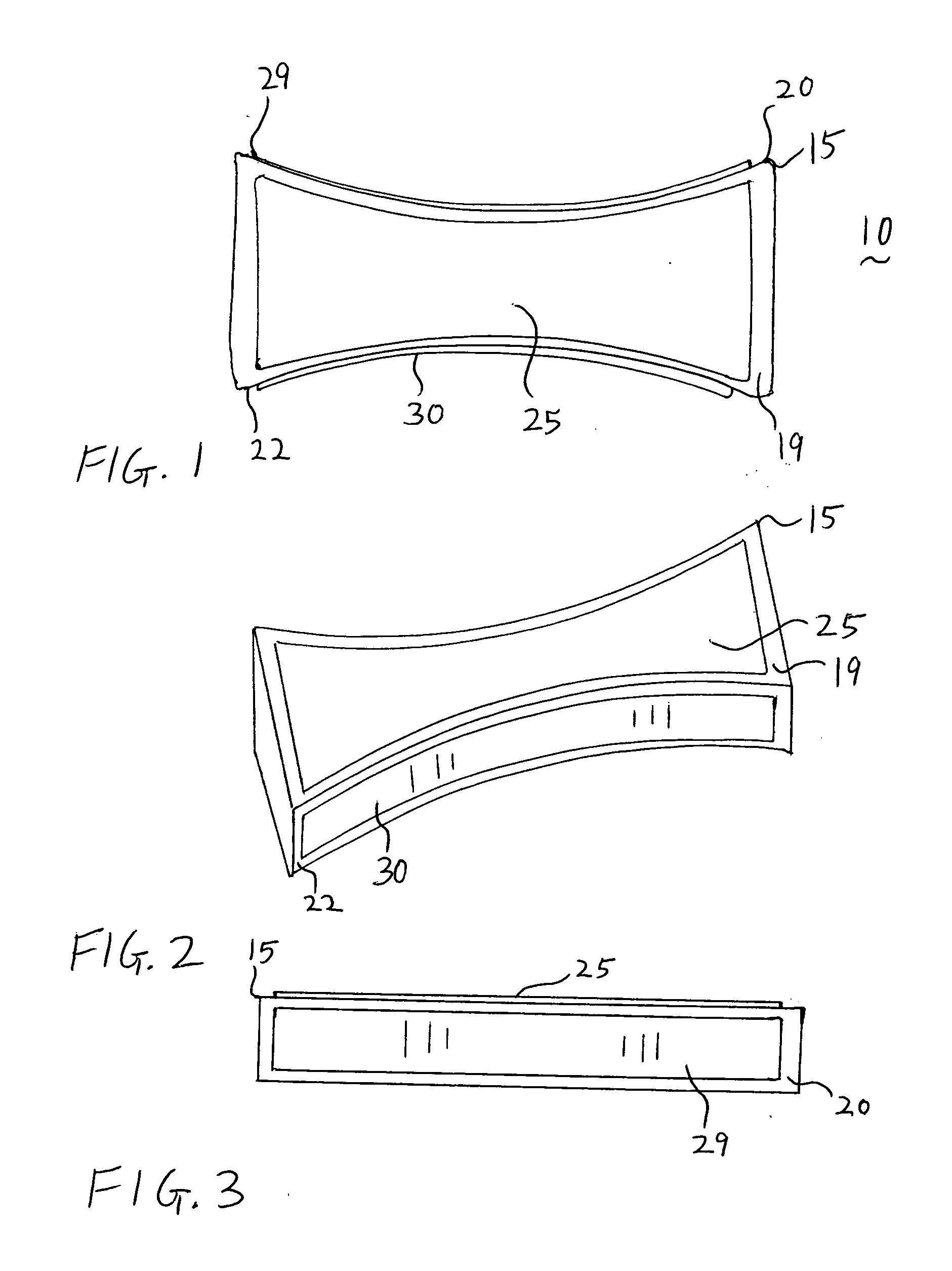

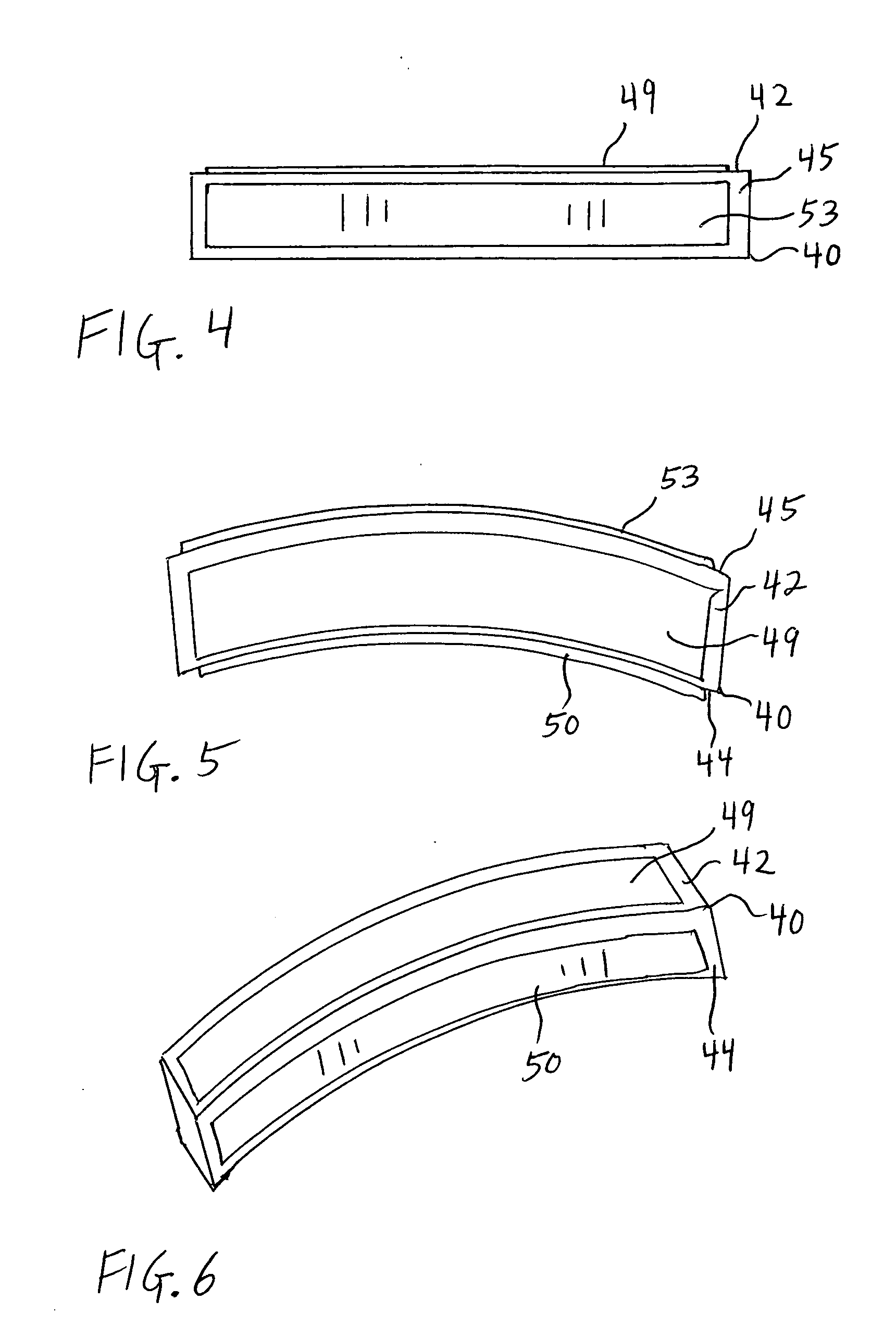

[0021] In the present invention as shown in FIGS. 4 to 6, the device 10 for sculpting the fingernail of a user comprises a block 40 of a predetermined material having a front surface 42, a first side surface 44, and a second side surface 45 opposed to the first side surface 44. The block 40 shown in this embodiment is also made of a lightweight foam material. The first side surface 44 is curved inward to form a concave arch, and the second side surface 45 is curved outward from the block to form a convex arch as shown in FIGS. 5 and 6. The front surface 42 has a layer of abrasive material 49 placed thereon, which in this embodiment shown is a sheet of sandpaper made of sand or another abrasive material. The first side surface 44 has a layer of second abrasive 50 material placed thereon, and the second side surface 45 has a layer of third abrasive material 53 placed thereon. Each of the first, second, and third abrasive material has a different grit size. The first abrasive material ...

third embodiment

[0022] In the present invention as shown in FIGS. 7 to 9, the device 10 for sculpting the fingernail of a user comprises a block 60 of a predetermined material having a front surface 63, a first side surface 65, and a second side surface 66 opposed to the first side surface. The block shown in this embodiment is also made of a lightweight foam material. The first side surface 65 is curved inward to form a concave arch. The front surface 63 has a layer of abrasive material 69 placed thereon, which in this embodiment shown is a sheet of sandpaper made of sand or another abrasive material. The first side surface 65 has a layer of second abrasive 70 material placed thereon, and the second side surface 66 has a layer of third abrasive material 73 placed thereon. Each of the first, second, and third abrasive material has a different grit size. The first abrasive material 69 has the most coarse grit size and should be sufficient for filing the outer edges of the fingernail. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com