Compressor and gas cylinder containment and cooling apparatus

a technology of compressor and gas cylinder, which is applied in the direction of positive displacement liquid engine, pump components, piston pumps, etc., can solve the problems of increased risk, increased risk, and severe bodily harm or injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

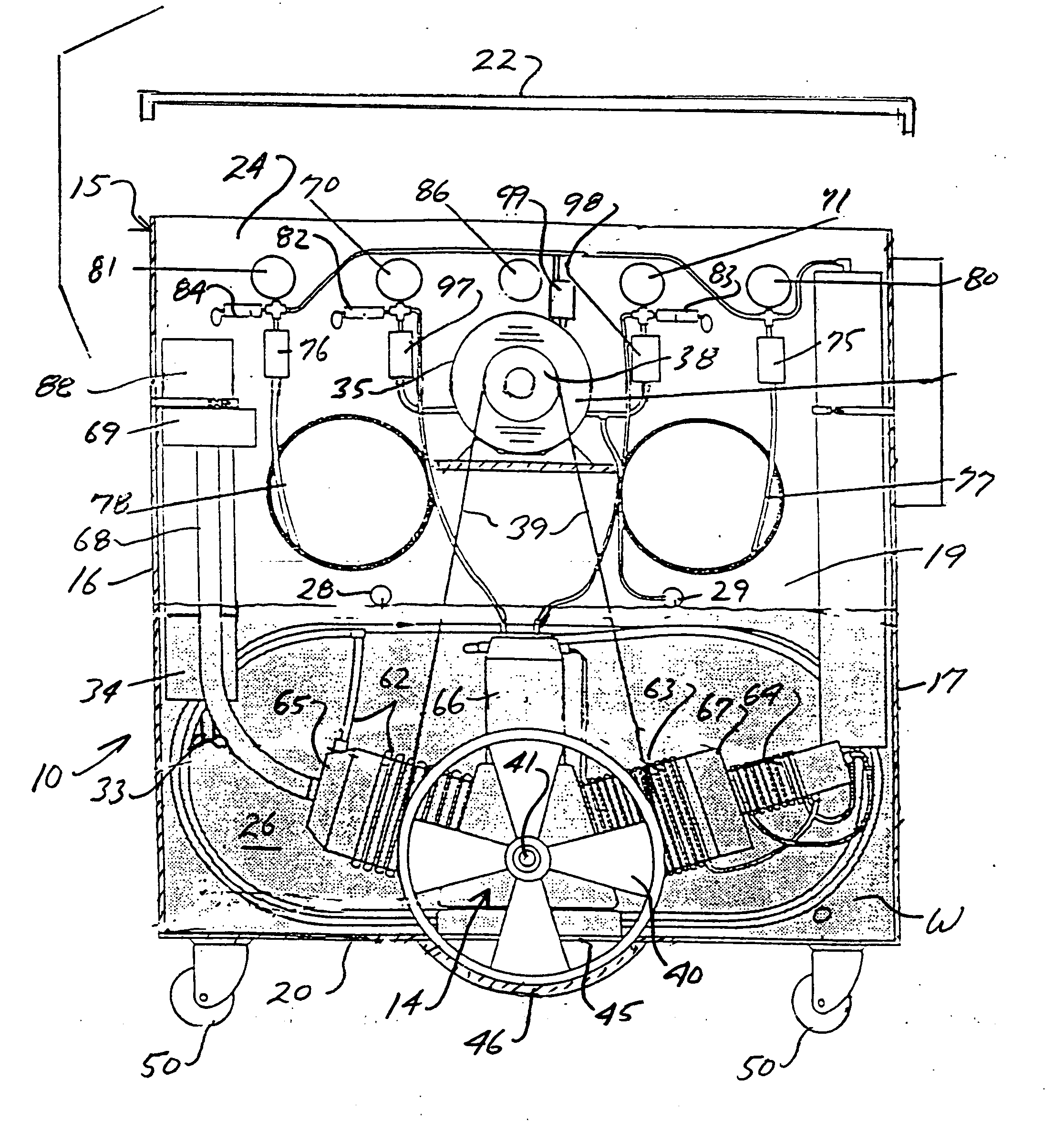

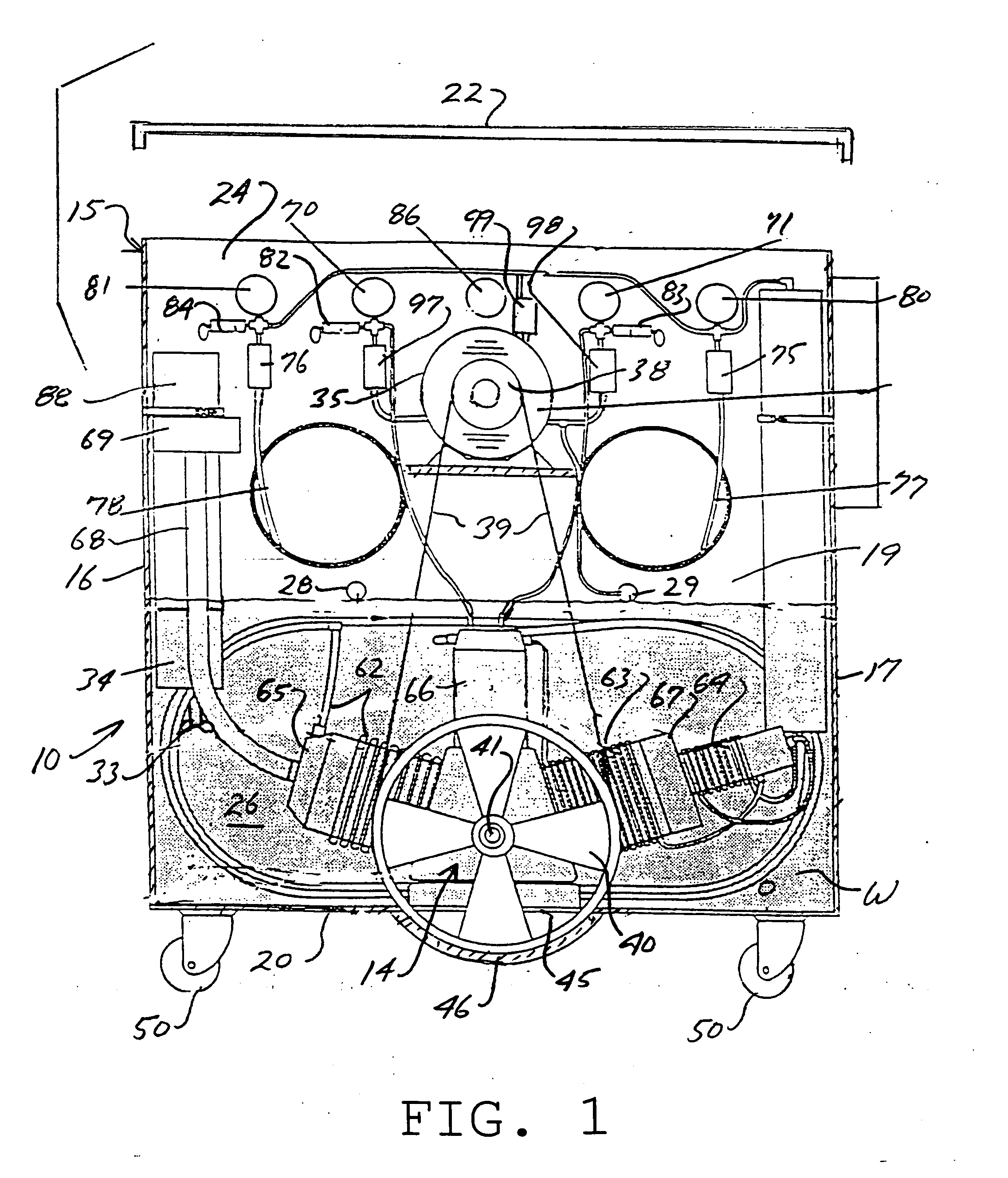

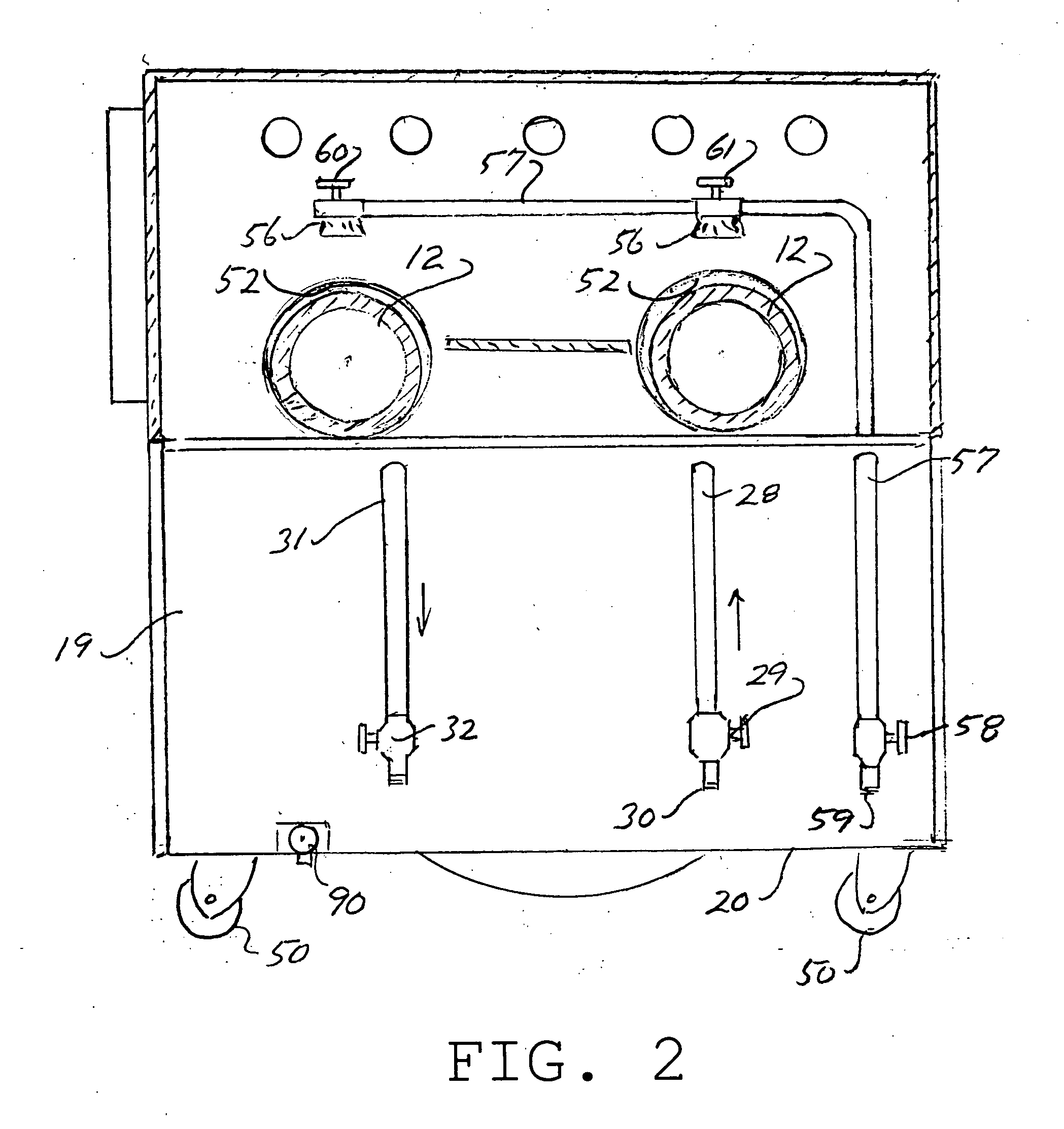

[0027] With continued reference to the drawings, a fragmentation containment unit 10 for charging or filling one or more gas bottles, cylinders or tanks 12, see FIG. 6., is shown. The cylinders may include the type used by scuba divers, fire fighters, rescue workers and the like that are of a size to be carried or worn during use. As previously described, such cylinders may be initially charge with gas pressures up to 4500 to 6000 psi using conventional air or gas compressors such as shown at 14.

[0028] The containment unit 10 includes a housing 15 constructed of at least three sixteenth of an inch thick steel plate and have opposite side walls 16 and 17, front and rear walls 18 and 19 and bottom wall 20. Preferably, the front and opposite side walls are formed of a single piece of material bent or formed into a u-shaped configuration that mates with an L-shaped piece that forms the rear and bottom walls. These two pieces are welded along their common joint areas such that the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com