Low profile bathtub assembly

a bathtub and low-profile technology, applied in the field of low-profile bathtub assembly, can solve the problems of time-consuming and expensive processes, and achieve the effect of low profile and convenient draining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

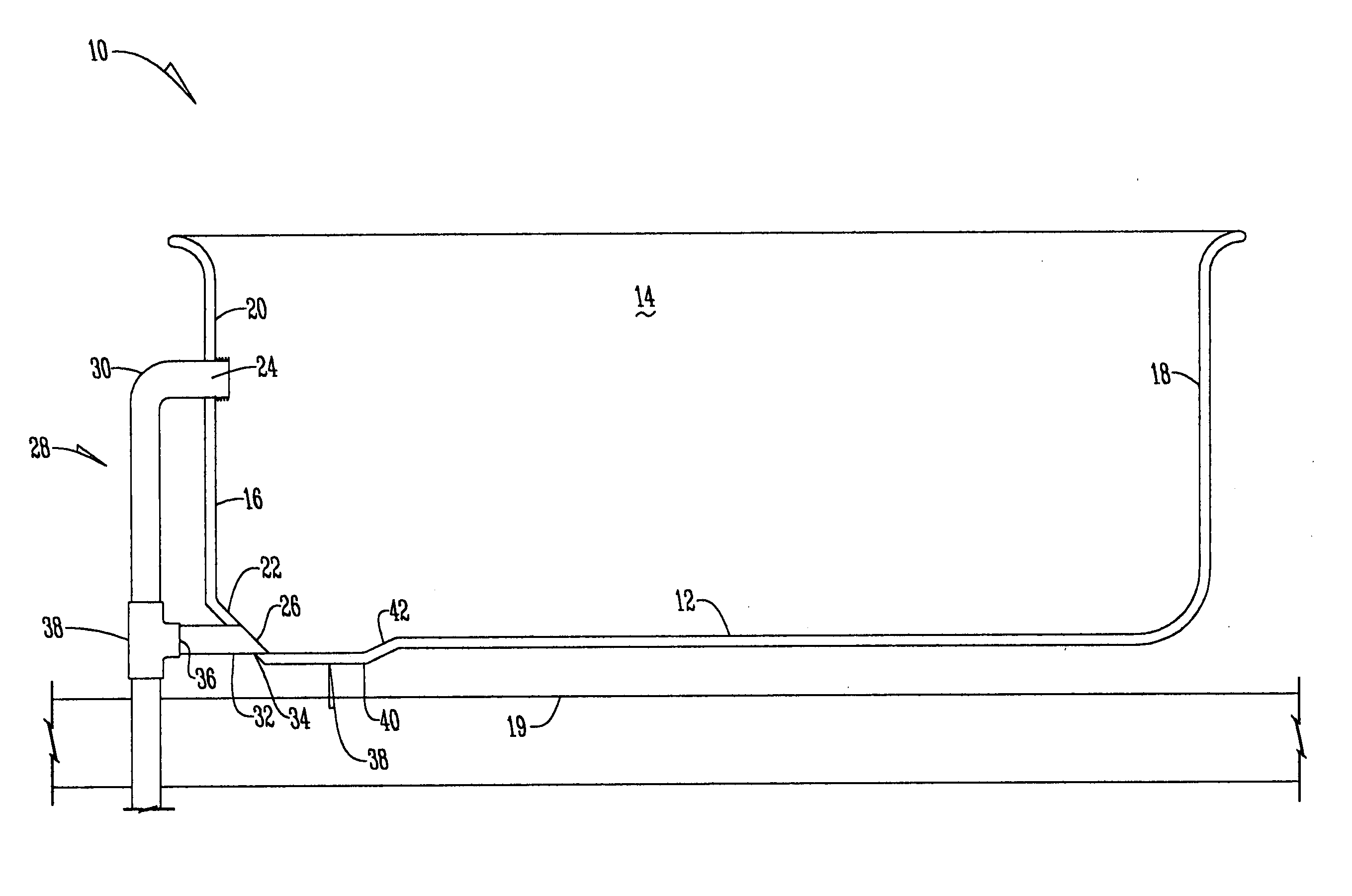

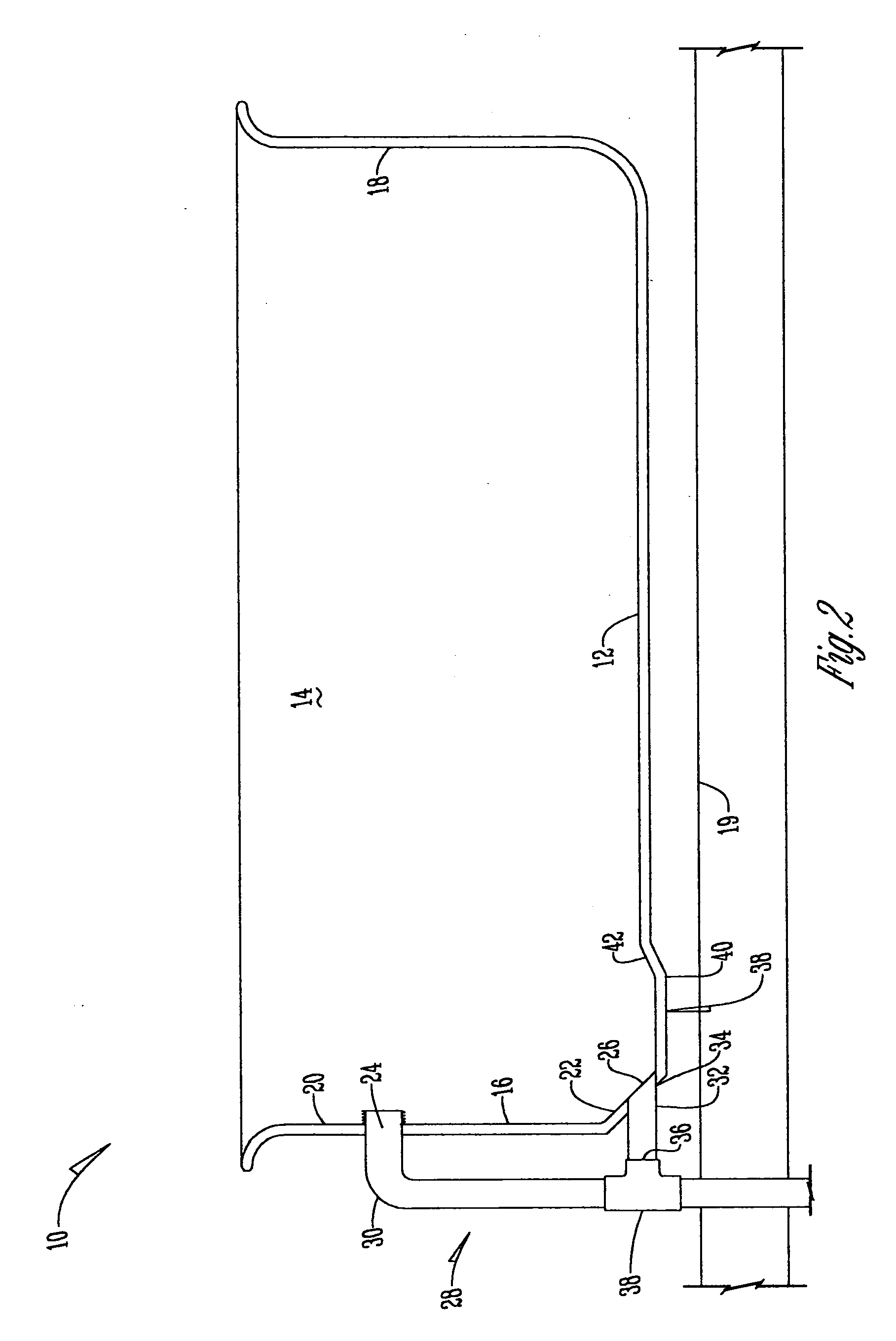

[0010] Referring to FIG. 2, the bathtub 10 of the present invention has a bottom 12, sidewalls 14, and end walls 16 and 18. The end wall 16 has a generally vertical portion 20 and a tapered or angled portion 22 that terminates in the bottom 12. Positioned within the vertical portion 20 is an overflow port 24 and positioned within the angled portion 22 of the end wall 16 is a drain port 26.

[0011] Connected to the bathtub 10 is a drain assembly 28 having an overflow pipe 30 that is connected to the overflow port 24 in any conventional manner. The drain assembly 28 also has a drain pipe 32 that is connected to the drain port 26 at a first end 34 and is connected to the overflow pipe at a second end 36. The drain pipe 32 is connected to the overflow pipe 30 in any conventional manner such as integrally formed or connected by a T-bar 38 as shown in FIG. 2. The first end 34 of the drain pipe 32 may be angled to fit the drain port 26 or a connector (not shown) is used to connect a convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com