Modular pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

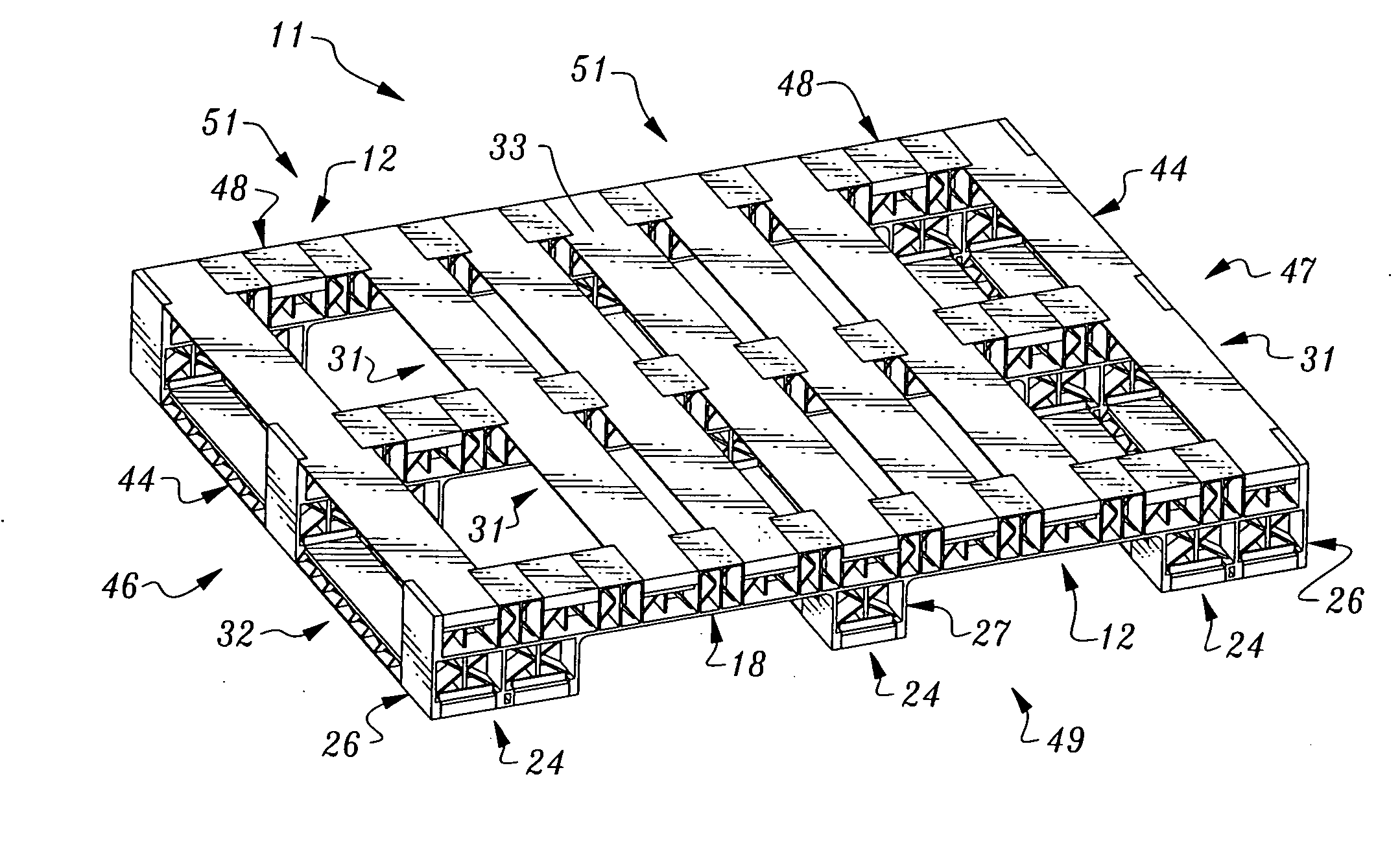

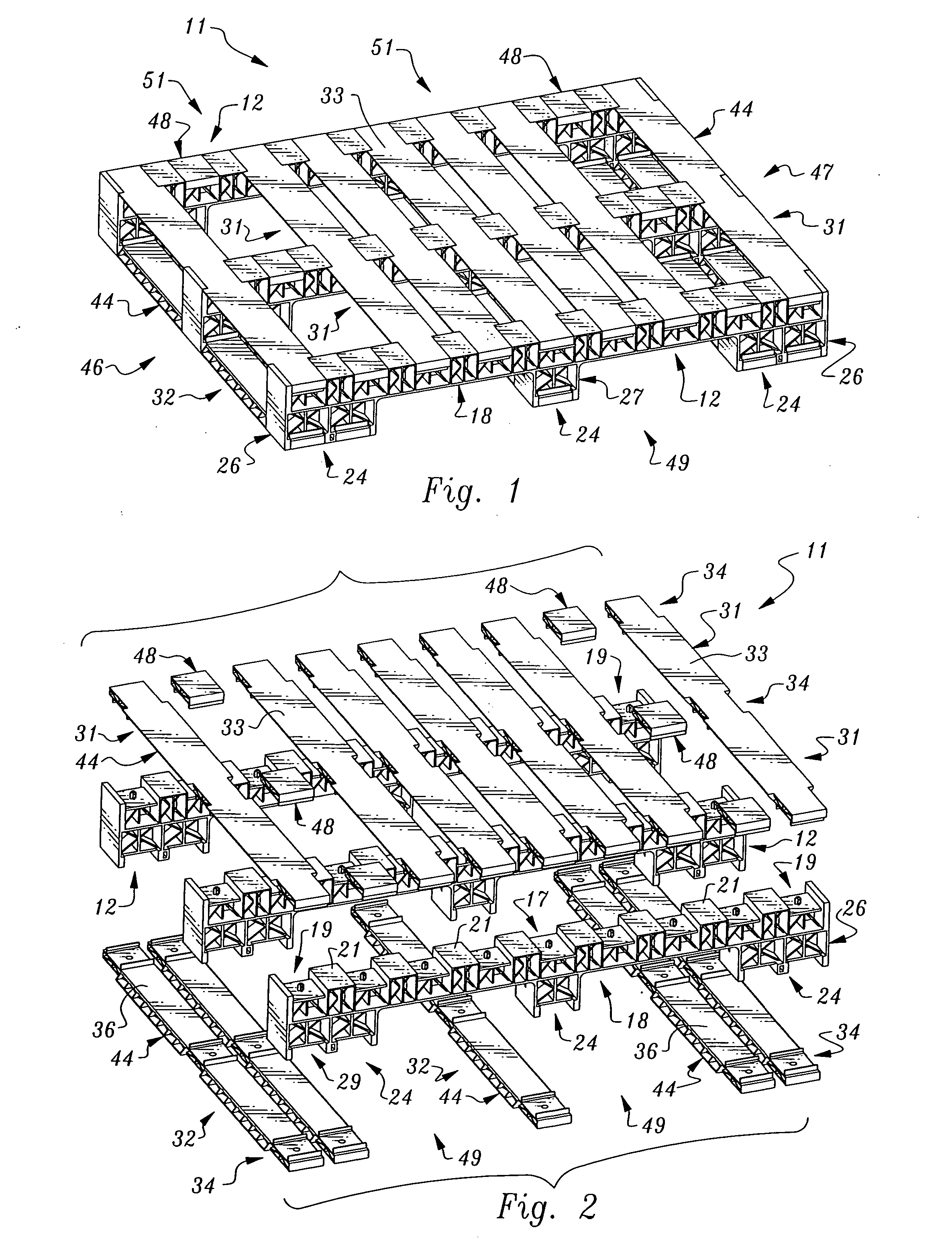

[0036] Turning now to the drawings, and in particular to FIG. 1, the modular pallet 11 of the present invention is comprised of a plurality of elongated runner beams 12 arranged in spaced, parallel relation. The longitudinal axis of each runner beam is oriented parallel to the longitudinal axis of the pallet. Typical pallets are sized 40″×48″, so the length of the runner beams for such a typical pallet would be 48″. However, this dimensional information is provided only for example, and not by way of limitation to the disclosure herein.

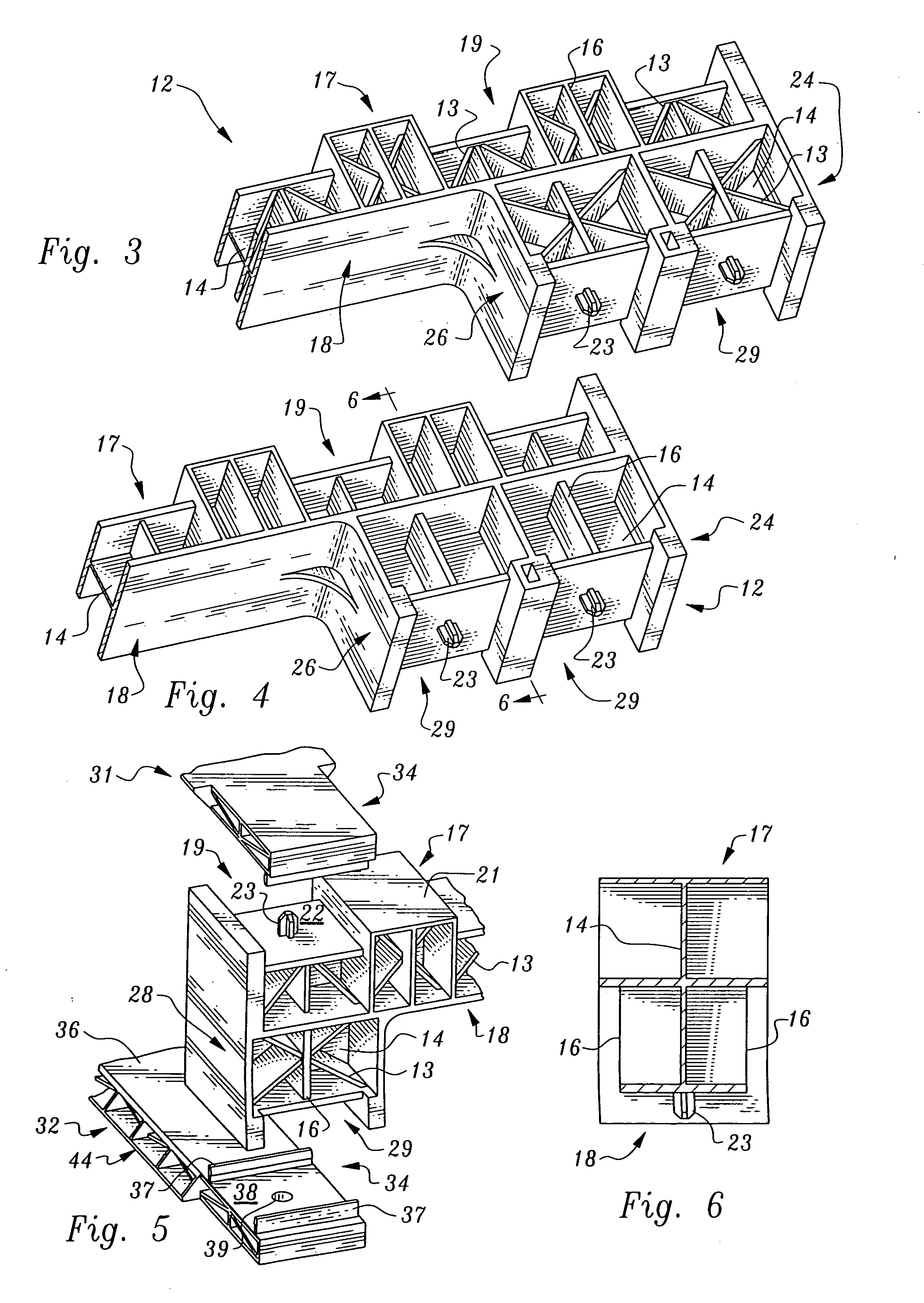

[0037] Structural reinforcement means are provided throughout the runner beams 12, to resist both compressive and bending forces applied by the load on the pallet structure. These forces are particularly great when the pallet is picked up by a forklift or a pallet jack, and transported onto or off of a transport vehicle. To resist such forces, diagonal bracing 13, longitudinal vertical walls 14, and transverse vertical walls 16 are employed. In FIG. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap