Photographic printing system and method for application of multiple masks in coloring refractory metals

a printing system and refractory metal technology, applied in the field of photographic printing system and method for applying multiple masks in coloring refractory metals, can solve the problems of difficult, if not impossible, to transfer this precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

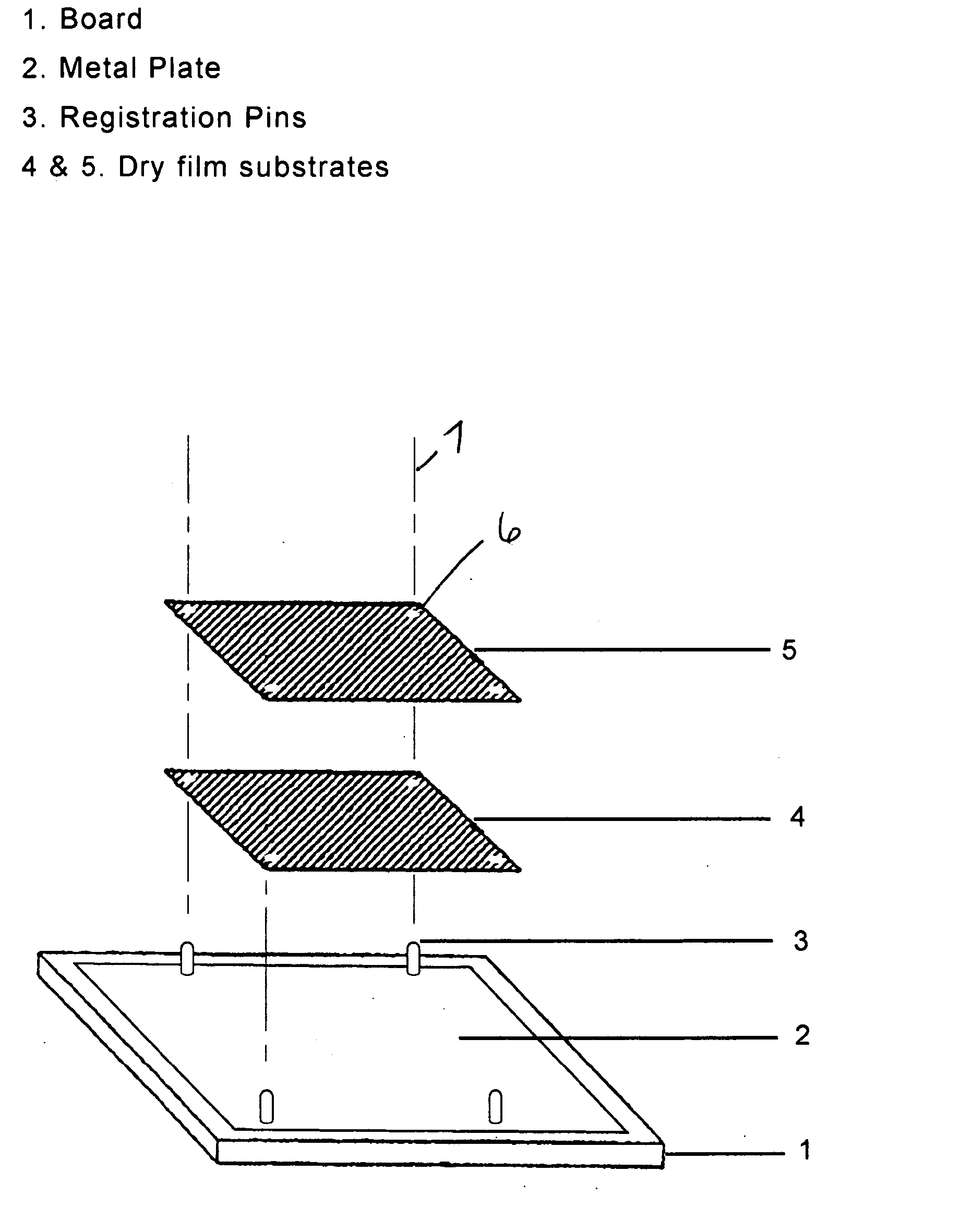

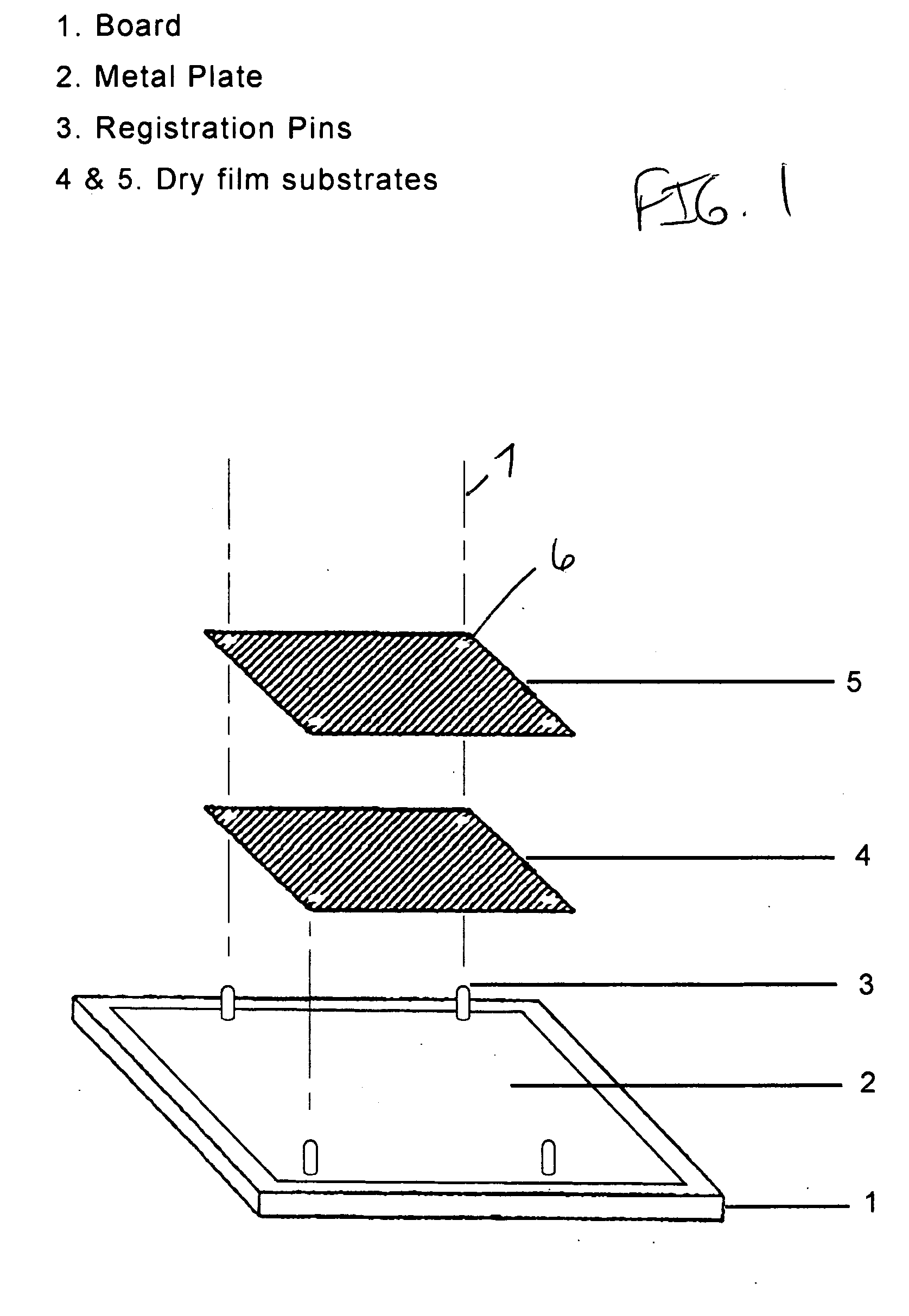

[0011] The present invention is a photographic printing system and method for application of multiple masks in coloring refractory metals. The present invention applies multiple masks to color refractory metals through anodization with precise registration, including process color.

[0012] In offset, four color printing, color separations are made to give the illusion of continuous tone, photographic images using only four colors of ink. Other printing systems including Hexachrome using six colors or four colors plus one or more spot colors can also be used. This same photographic image can be achieved through an entirely different method of the present invention of color separation and assigned to dry or wet film masks to anodize refractory metals. The method of the present application is accurate to at least 85 dpi, similar to the resolution of color newspaper printing.

[0013] In the practice, a mask resists the anodization process and can be removed to add additional masks to crea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| computer graphic imaging | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com