Baluster assembly

a technology of assembly and clusters, applied in the direction of clusters, building components, pillars, etc., can solve the problems of relative heavyness and relatively high production cost, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

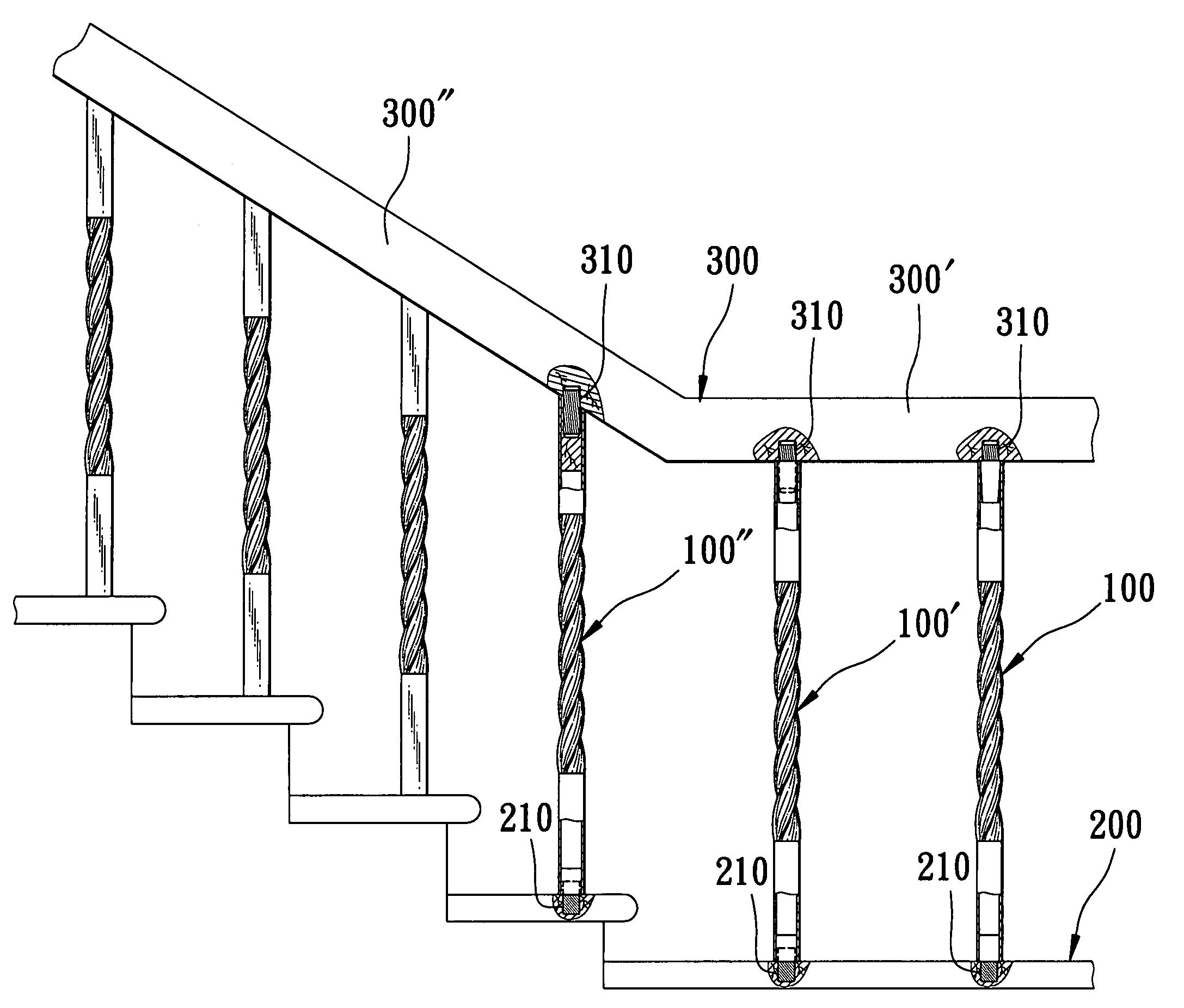

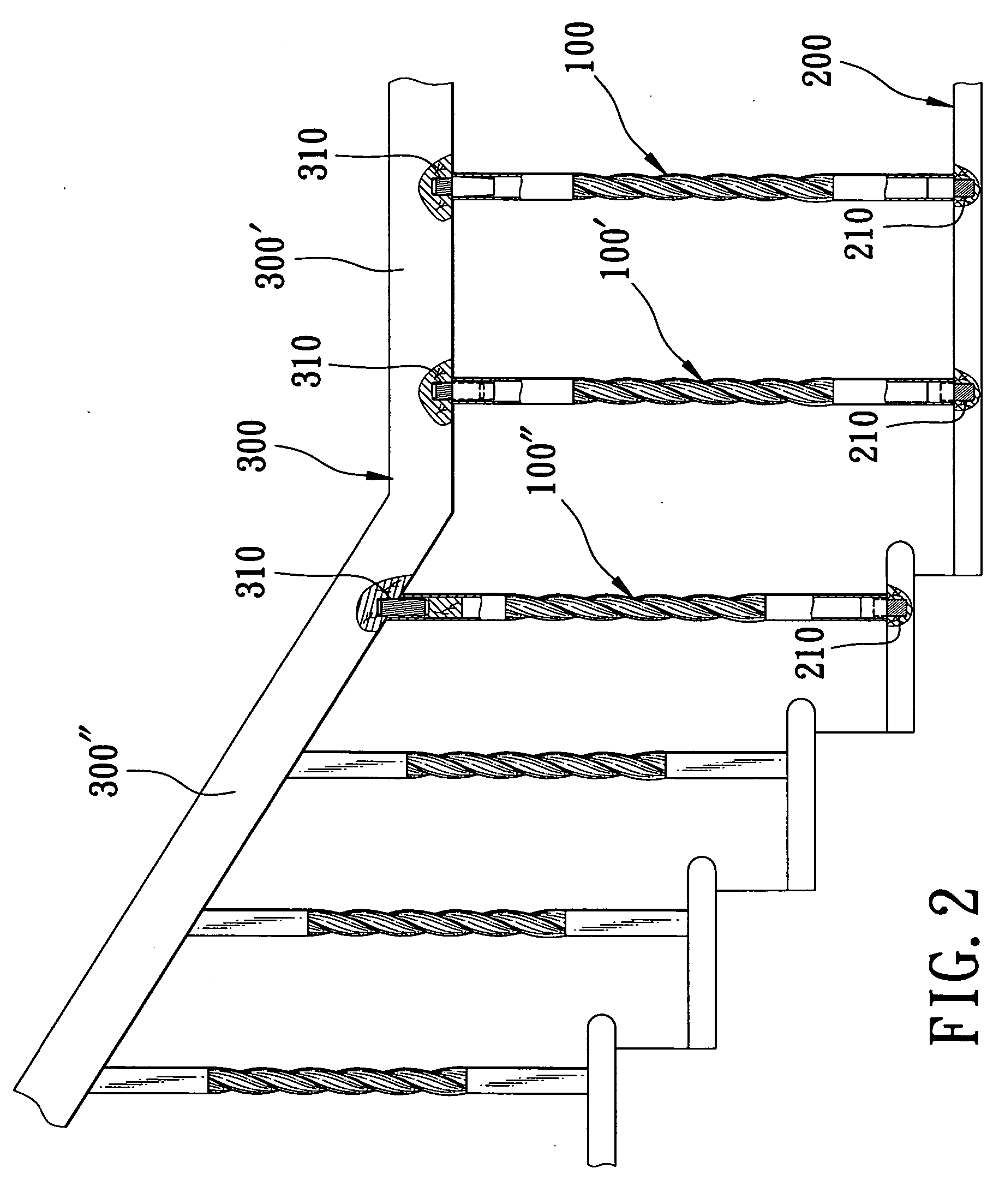

[0015] Referring to FIG. 2, the first, second and third preferred embodiments of a baluster assembly 100, 100′, 100″ according to this invention is shown to be installed between a base 200 and a handrail 300. The base 200 is provided with a plurality of holes 210, and the handrail 300 is provided with a plurality of holes 310 corresponding to the holes 210 in the base 200.

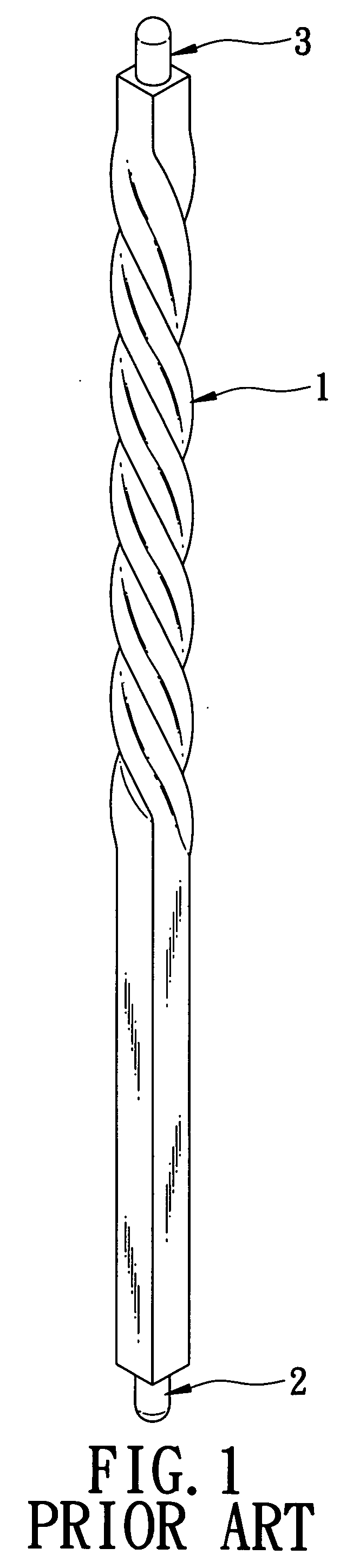

[0016] Referring to FIG. 3, the first preferred embodiment of the baluster assembly 100 is shown to include a hollow post 10, a top connecting element 30 mounted on top of the hollow post 10, and a bottom connecting element 20 mounted on the bottom of the hollow post 10.

[0017] The hollow post 10 is made from a metal tube, has a top end section 112, a bottom end section 111 opposite to the top end section 112, and an intermediate patterned section 113 extending between the top and bottom end sections 112, 111 along a longitudinal axis (L). The first preferred embodiment of the baluster assembly 100 is suitable for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com