Heat exchanger

a technology of heat exchanger and fin, which is applied in the direction of tubular elements, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of inability to introduce cooling air to the inter-louver path, inability to improve inability to easily catch cooling air by the louver wall surface, etc., to achieve the effect of improving the heat transfer rate of the fin, shortening the louver width, and improving the performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

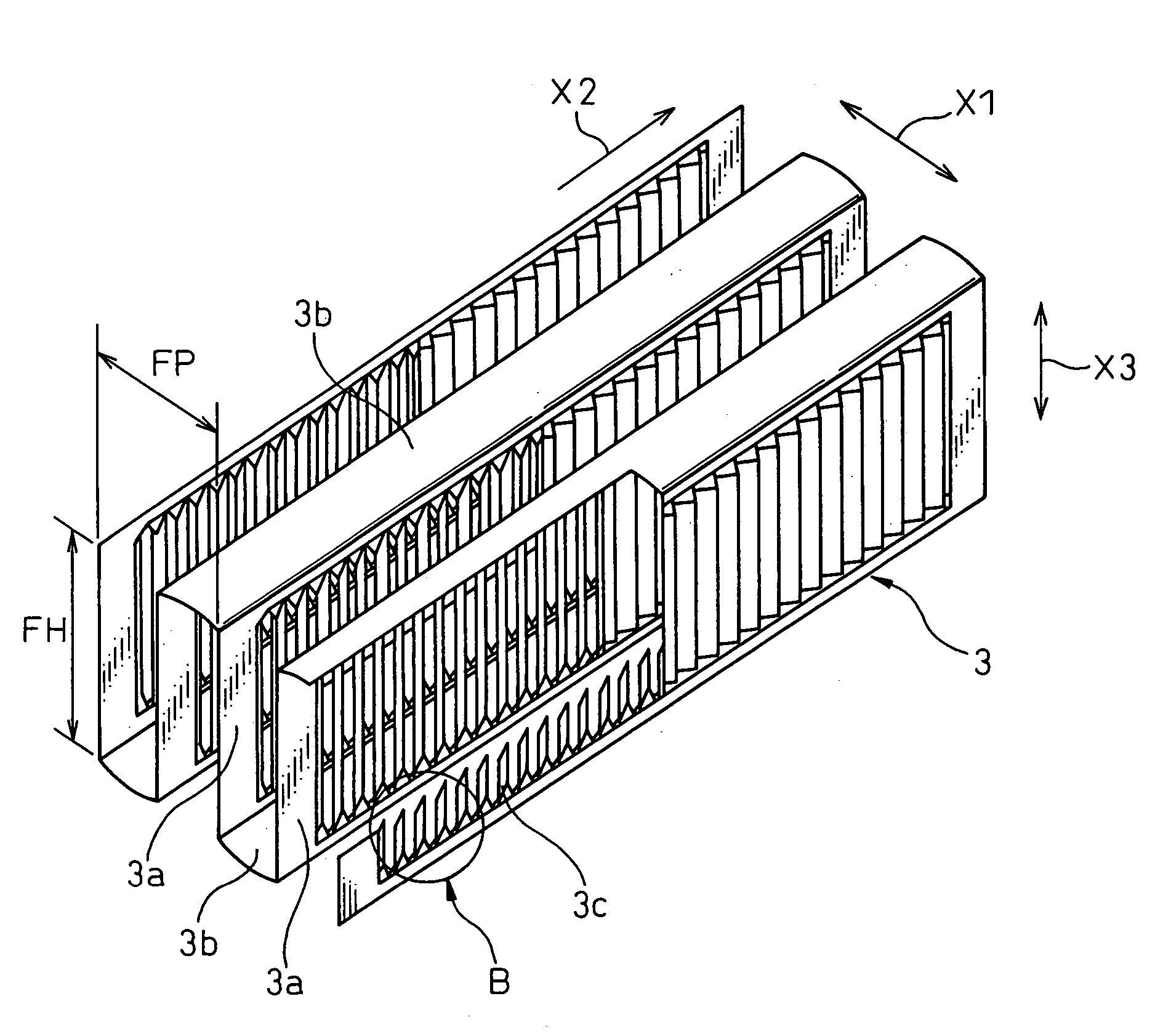

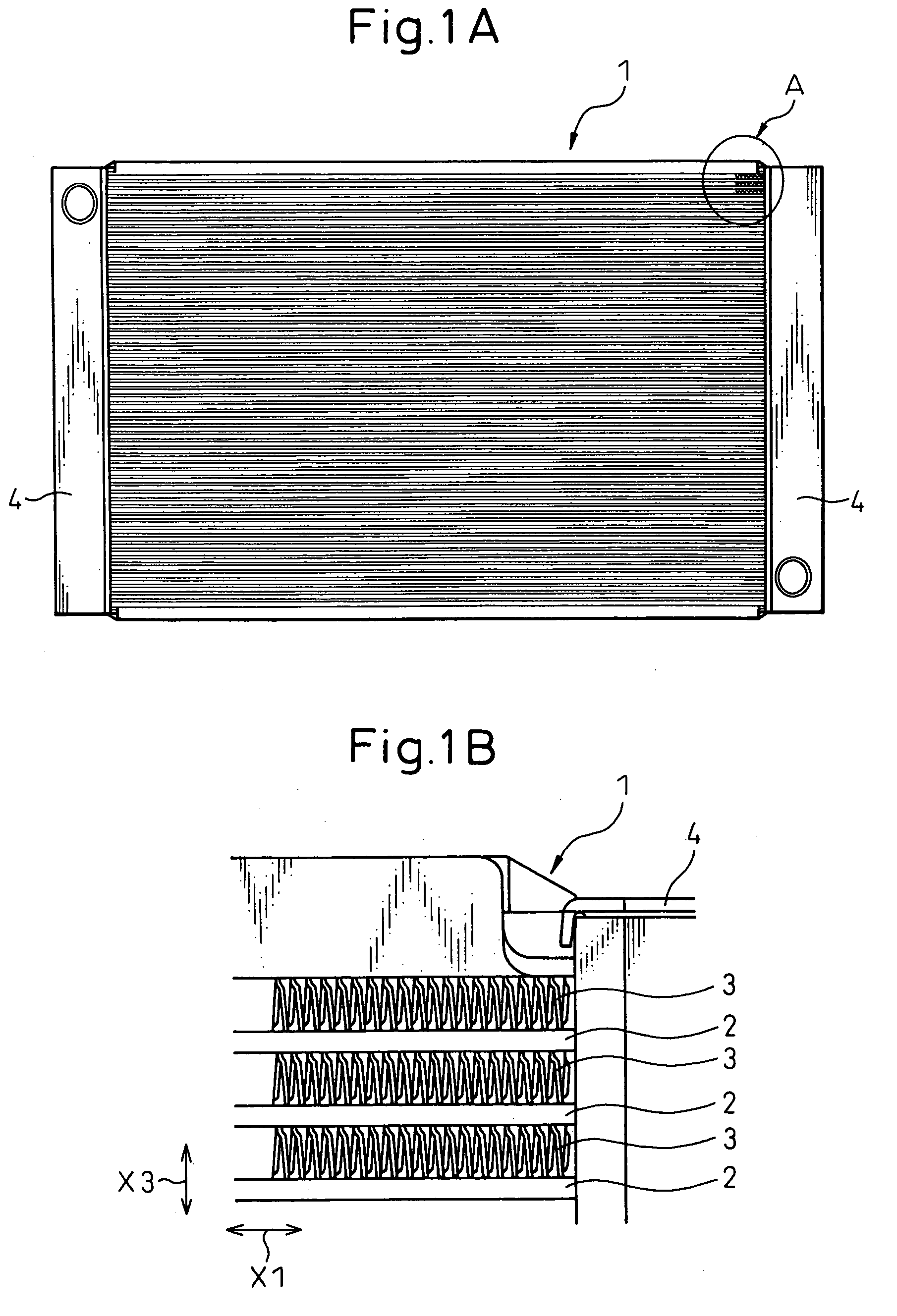

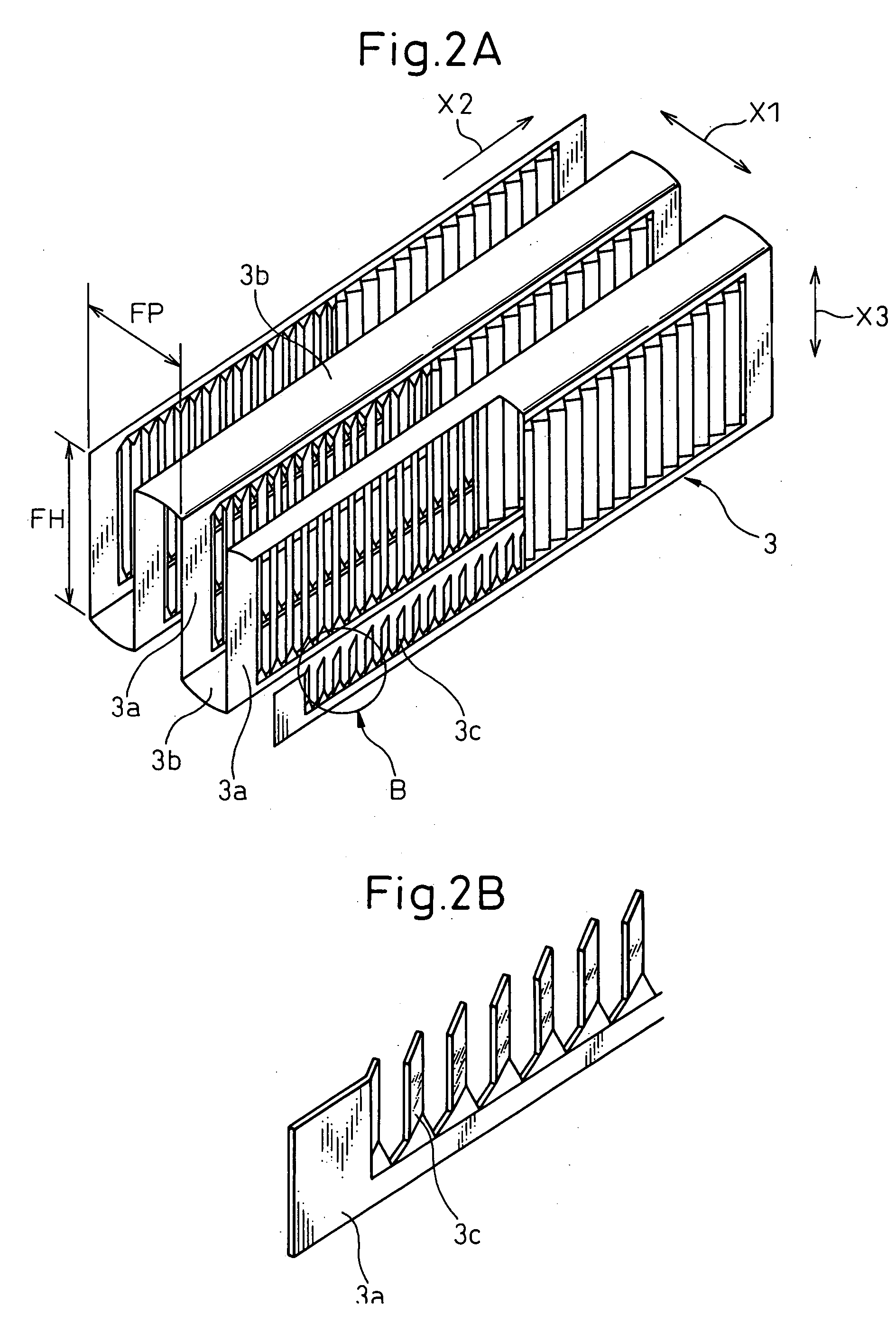

[0029] A heat exchanger according to a first embodiment of the invention is used as a radiator for cooling the cooling water of a vehicle engine (internal combustion engine) by exchanging heat between the cooling water and the air. FIG. 1A is a front view of a heat exchanger according to a first embodiment of the invention. FIG. 1B is an enlarged view of a portion A in FIG. 1A. FIG. 2A is a partly cutaway perspective view of fins 3 shown in FIG. 1. FIG. 2B is an enlarged view of a portion B shown in FIG. 2A. FIG. 3 is a perspective view of the fins 3 of FIG. 1B as seen in a direction different from FIG. 2A. FIG. 4 is a side view of the fins 3 of FIG. 1B seen from the direction X3 along the fin height. FIG. 5 is a sectional view of the fins 3 of FIG. 1B seen from the direction X3 along the fin height. FIG. 6A is a sectional view schematically showing the fins 3 of FIG. 1B as seen from the direction X3 along the fin height. FIG. 6B is an enlarged view of a portion C in FIG. 6A.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com