Vehicle seat with a headrest

a headrest and seat technology, applied in the field of vehicle seats, can solve the problems of inconvenience and safety risks of reinstalling the headrest, and achieve the effect of convenient access for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

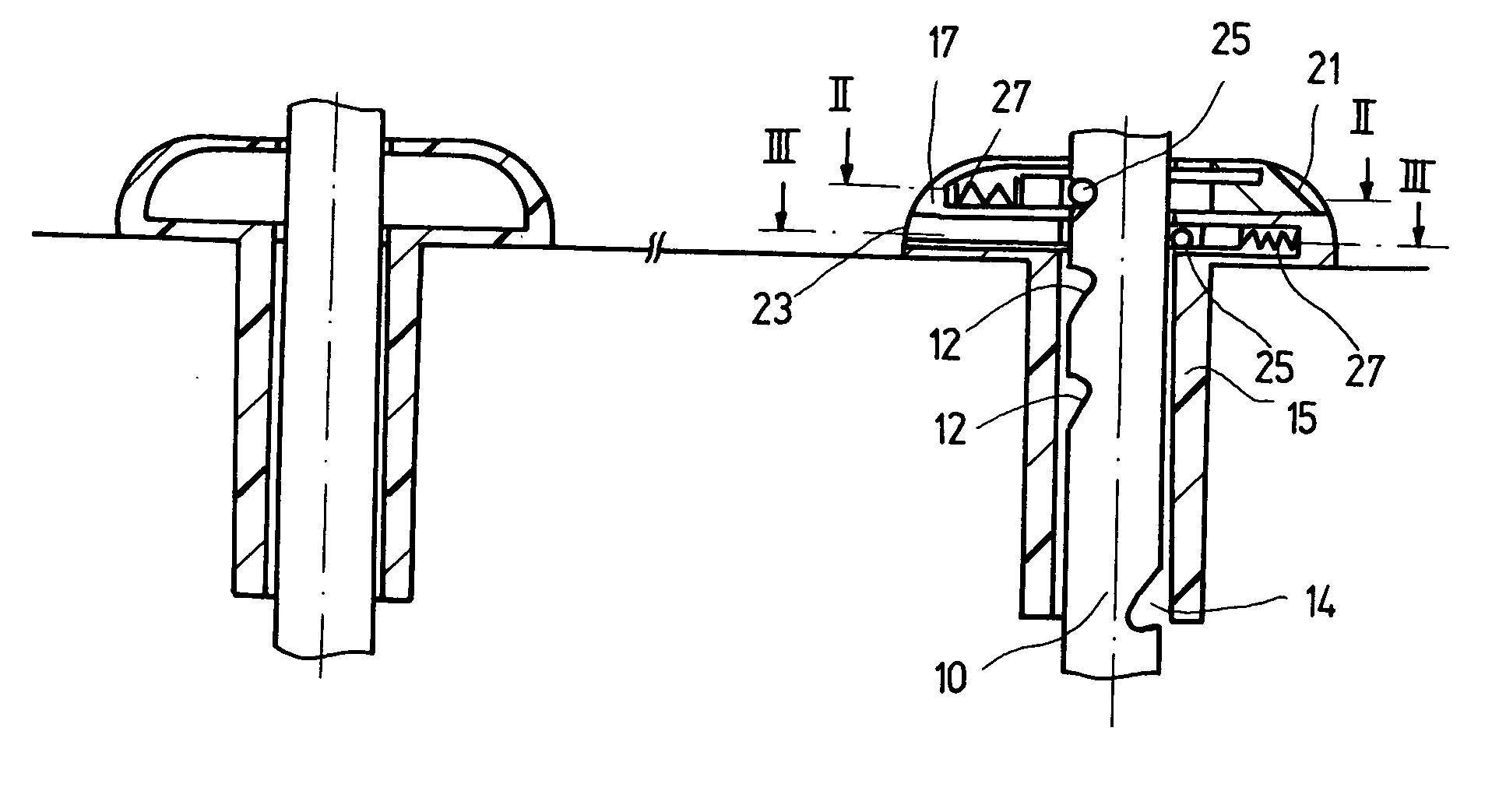

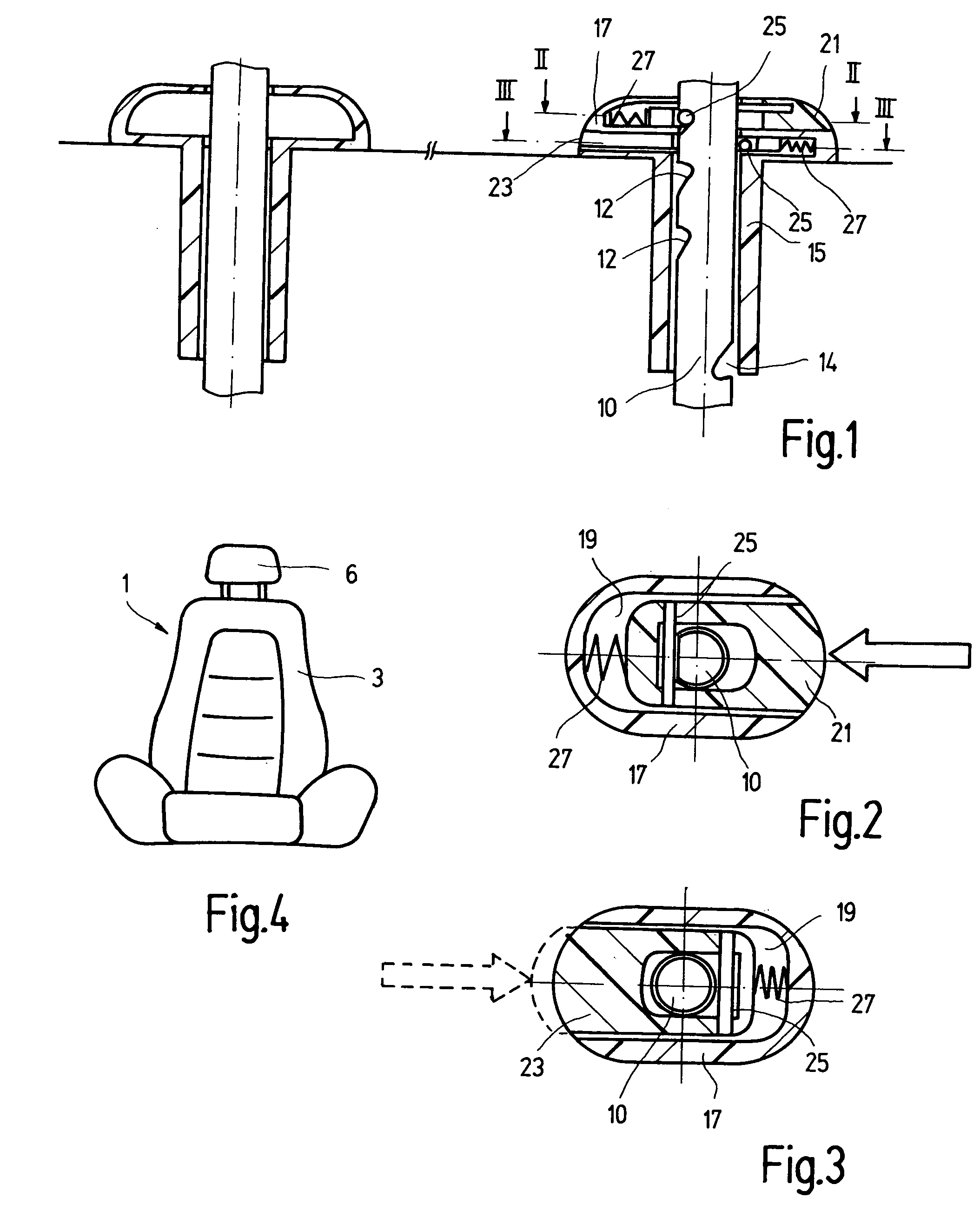

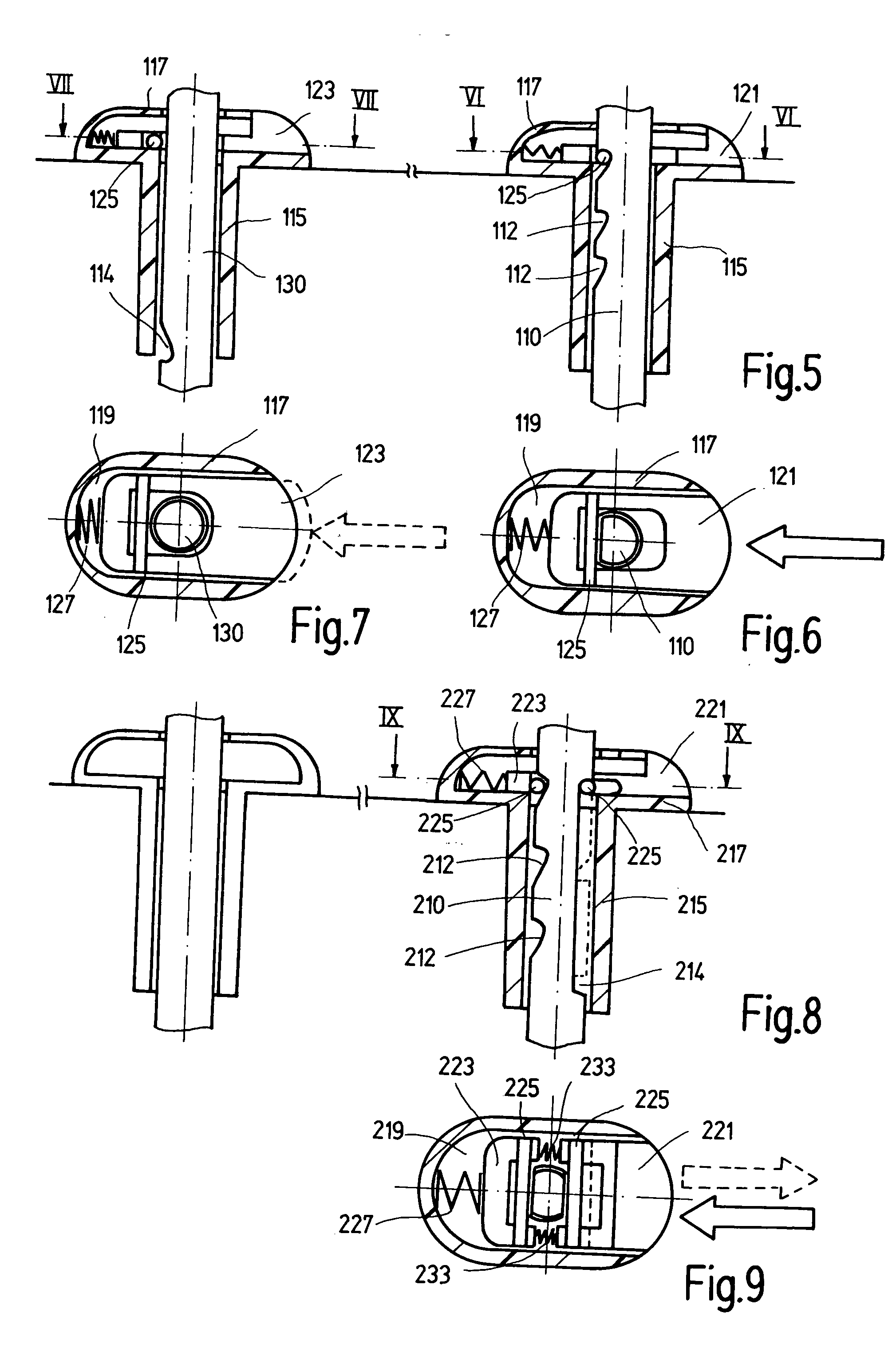

[0031] In the following, reference is made in greater detail to the drawings, in which like numerals refer to like parts throughout the several views. In all the exemplary embodiments, a vehicle seat 1 of a motor vehicle comprises a headrest 6 mounted on a backrest 3. The headrest 6 is attached in a known manner to at least one, and in the present case to two metal headrest rods, each of which is mounted in a linearly sliding manner in a plastic guide bushing in the backrest 3. By these means, the headrest 6, which is locked in an in-use position, is adjustable in height and can also be fully removed.

[0032] In the first exemplary embodiment, several adjustment notches 12 are arranged equidistantly apart on one side of one of the two headrest rods 10, and on the other side a stop notch 14 is formed below the lowest adjustment notch 12. The associated guide bushing 15 comprises a bushing head 17 within which are formed, at various heights and on opposite sides, two open receptacles 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com