Attachment device for building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

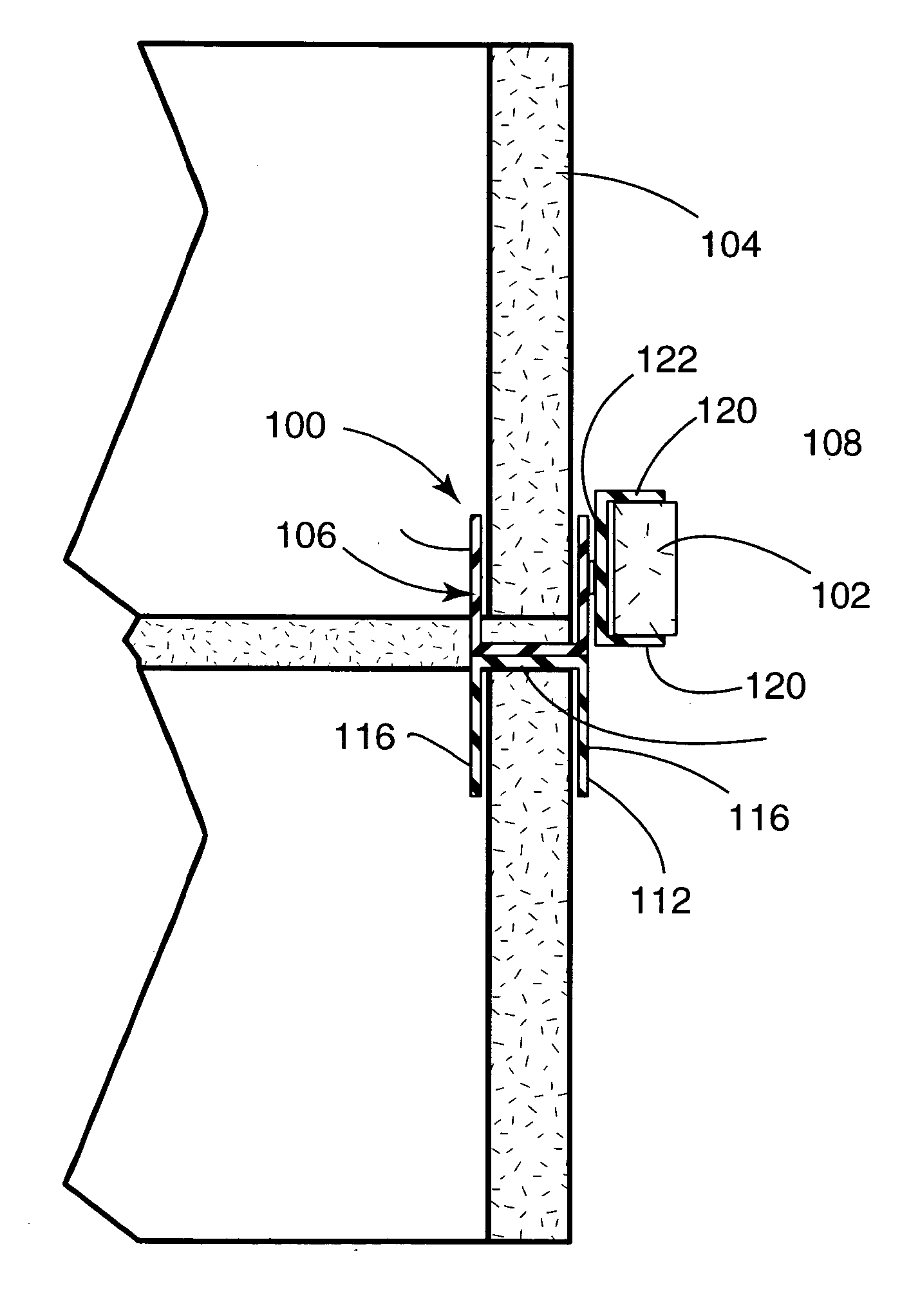

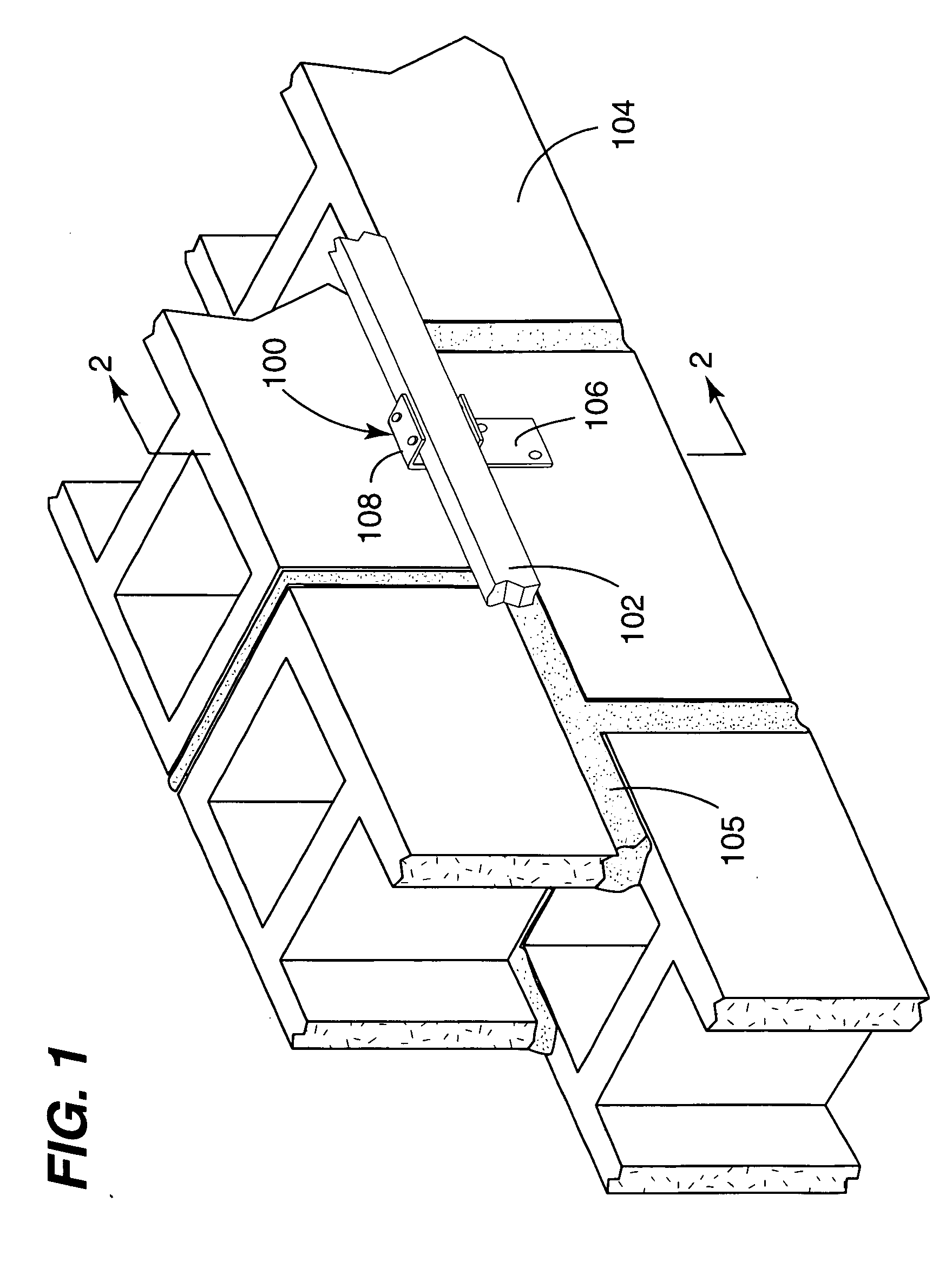

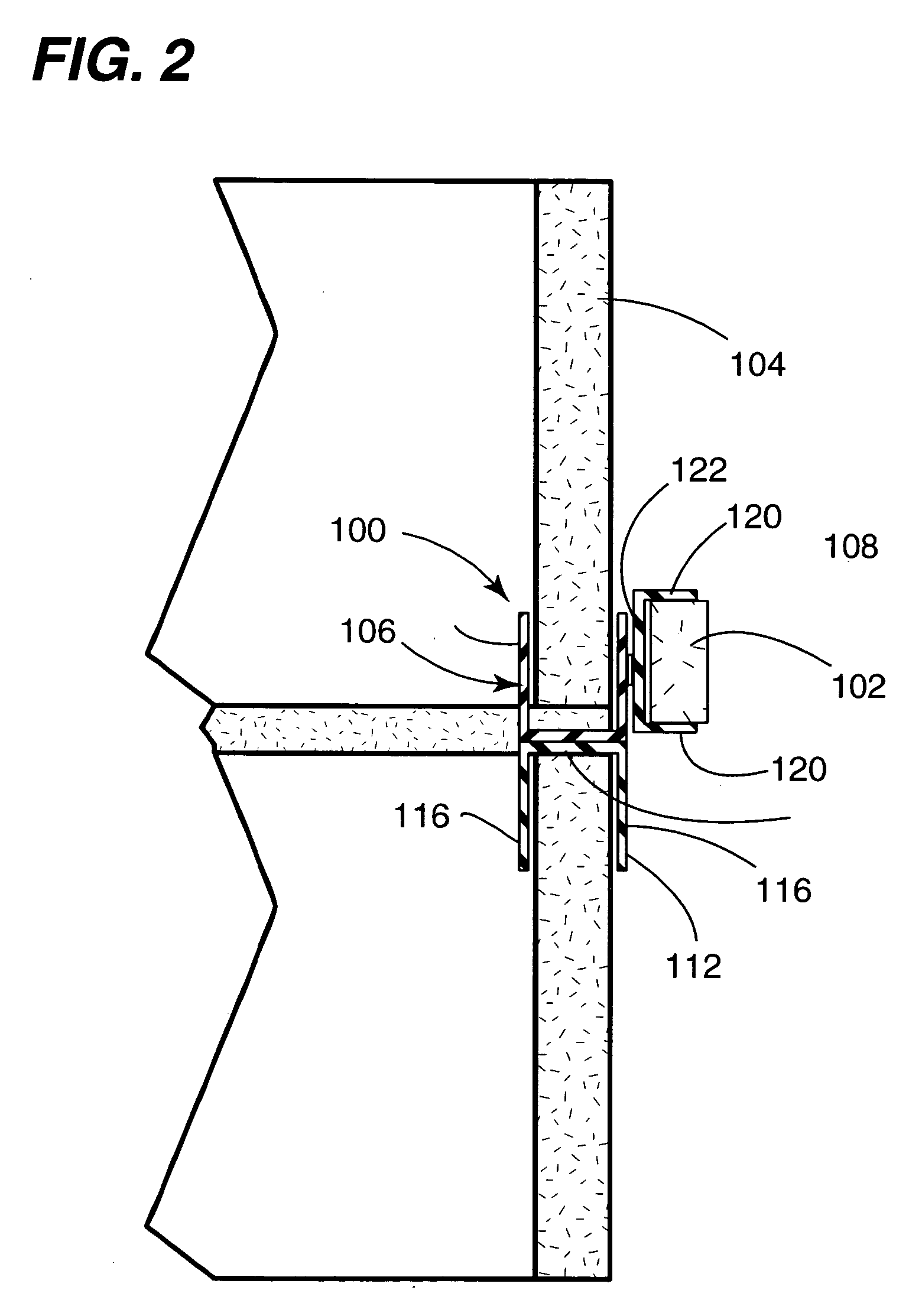

[0028]FIGS. 1-5 depict an embodiment of an attachment device for building materials in accordance with the present invention, referred to generally as the attachment device 100. As depicted in FIGS. 1 and 2, the attachment device 100 is suitably configured for attaching an elongated structural member 102 (e.g., a furring strip or stud) to a wall 104 constructed from, for example, masonry blocks (e.g., cinder blocks). During construction of the wall 104, the attachment device 100 and a plurality of other identical attachment devices are installed such that mortar 105 secures the attachment devices in place. Fasteners such as, for example, nails or screws are used to secure the elongated structural member 102 to the attachment member 100. Thus, a plurality of attachment devices in accordance with the present invention serves to secure elongated structural members (e.g., the elongated structural member 102) to the wall 104.

[0029] The attachment dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com