High-strength, lightweight blow-molded plastic structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A need therefore exists for structures constructed from blow-molded plastic that eliminates or reduces some or all of the above-described disadvantages and problems.

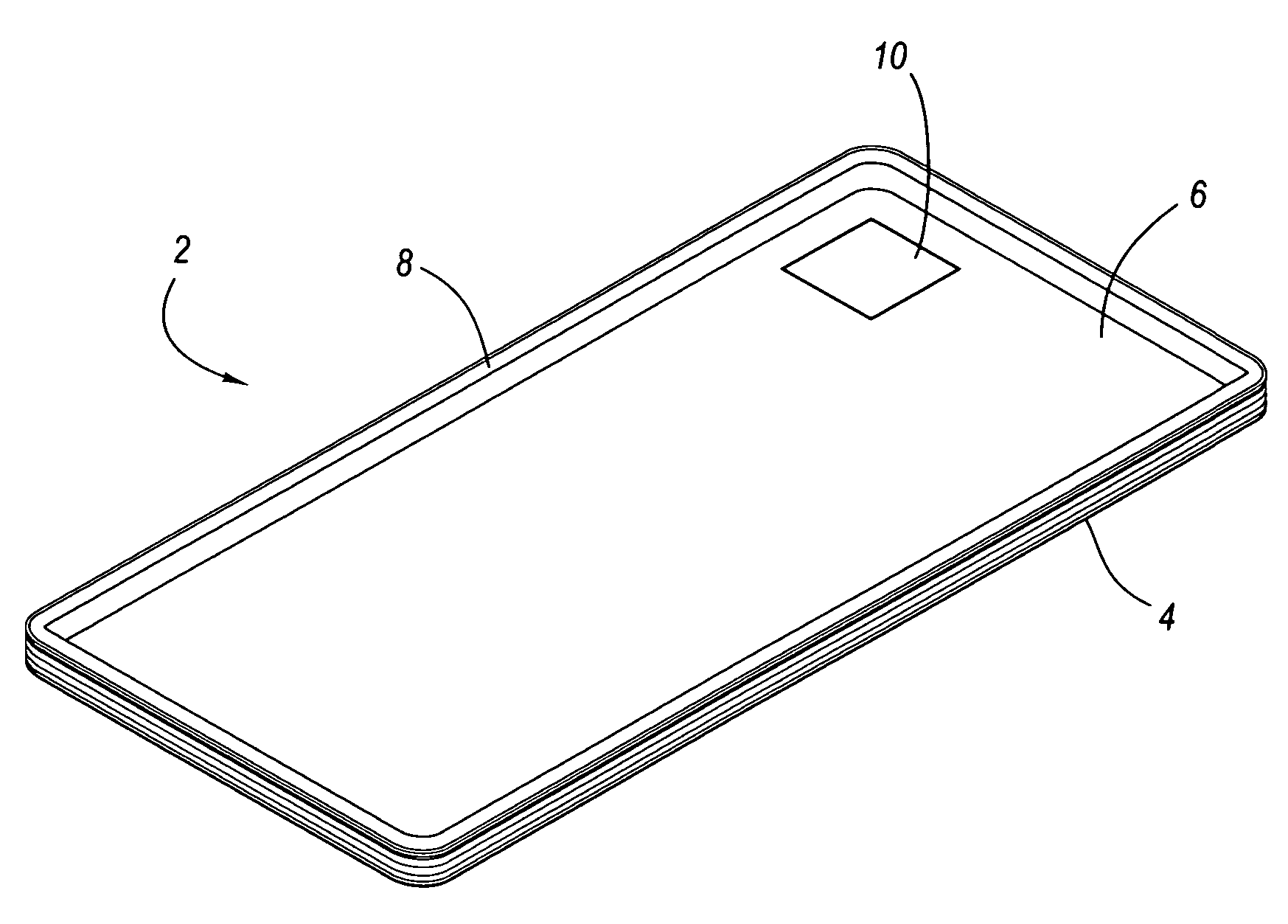

[0012] One aspect is a structure that can be constructed from blow-molded plastic and have increased strength. Preferably the blow-molded plastic structure has both increased strength and it is lightweight, but the structure does not have to be lightweight and high-strength.

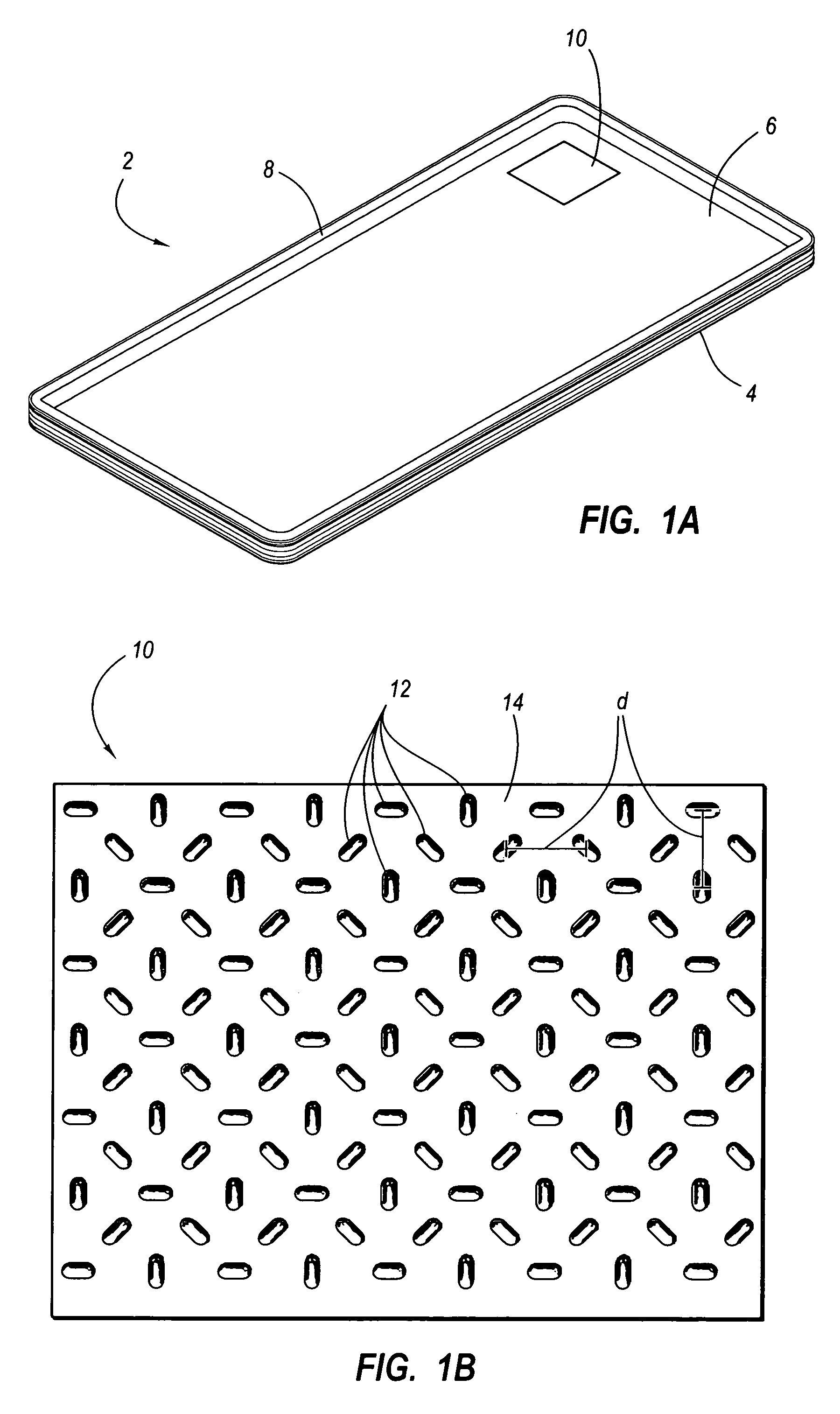

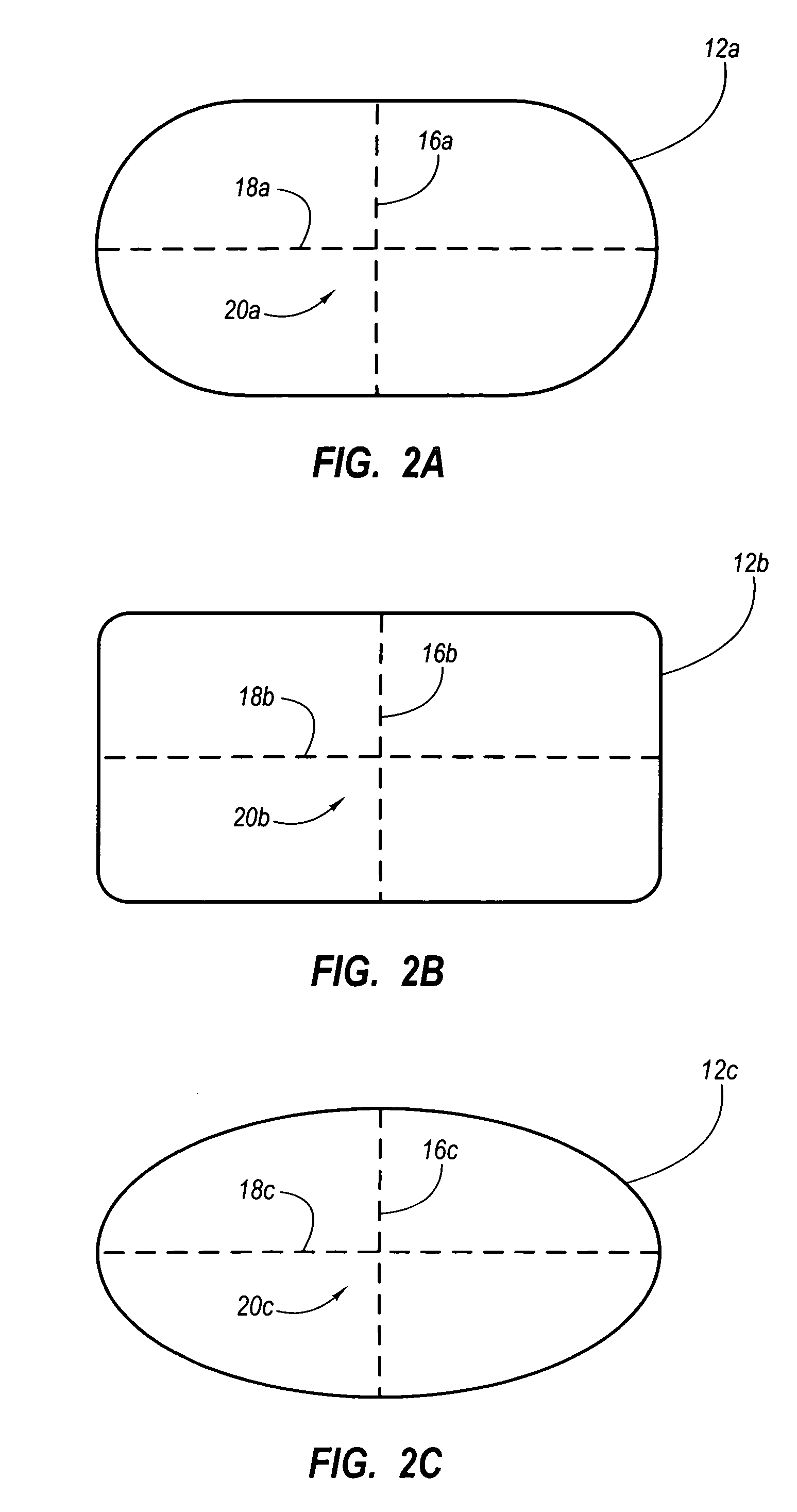

[0013] Another aspect is a structure that can be constructed from blow-molded plastic and include opposing surfaces. The opposing surfaces may be separated by a generally constant or other predetermined distances. For example, the opposing surfaces may include one surface that is generally planar and the other surface may include a plurality of depressions that are sized and configured to increase the strength of the blow-molded structure. The depressions may cover only a portion of the surface, substantially all of the surface, or the entire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com