Seed hopper and routing structure for varying material delivery to row units

a seed hopper and row unit technology, applied in the field of agricultural seeding implements, can solve the problems of difficult or impossible to change varieties on the go or with little downtime, difficulty or impossible to achieve proper variety control, and difficulty in rerouting or blocking material delivery, etc., to achieve convenient rerouting or blocking of material delivery, efficient utilization of hopper capacity, and quick change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

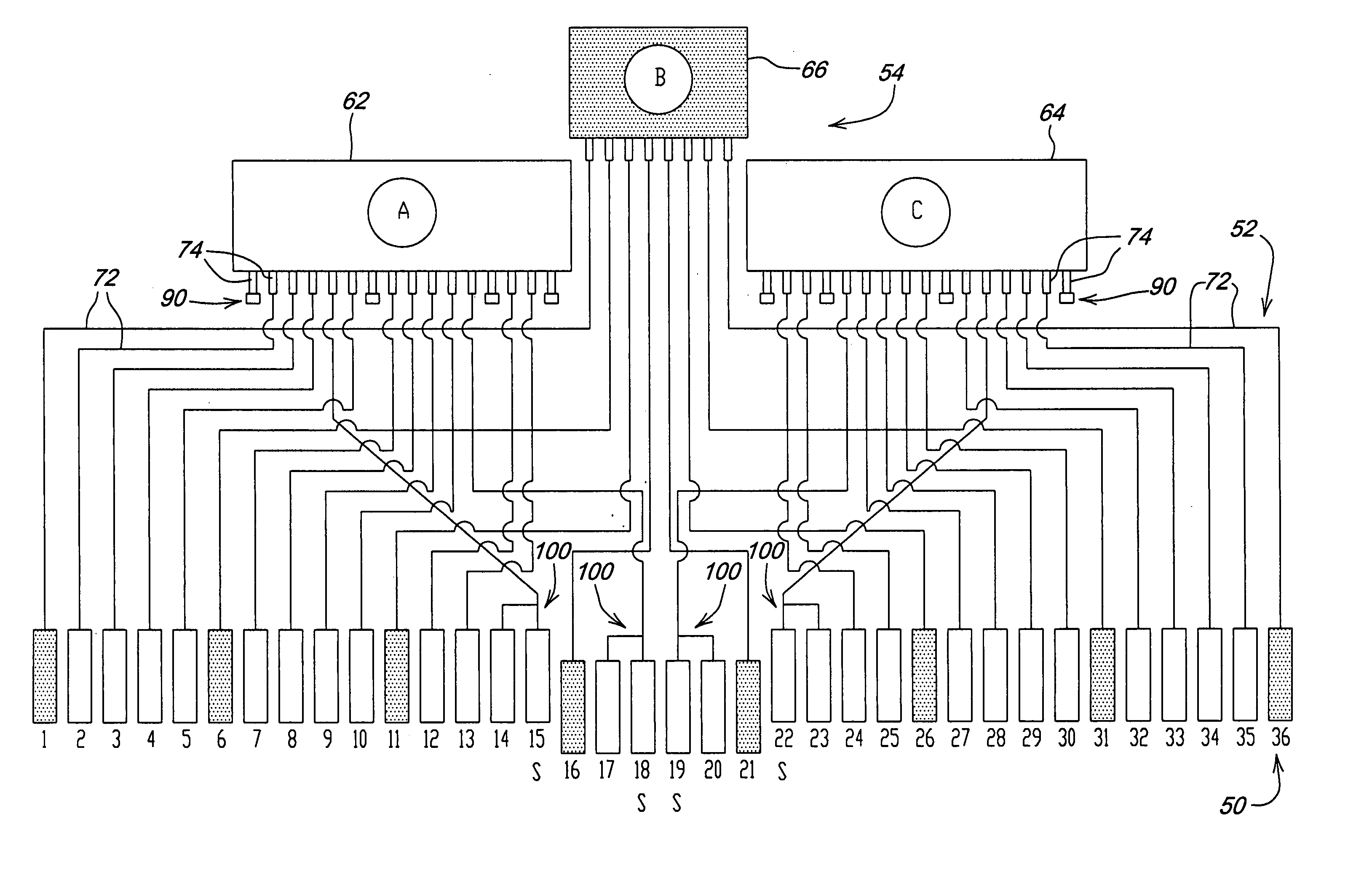

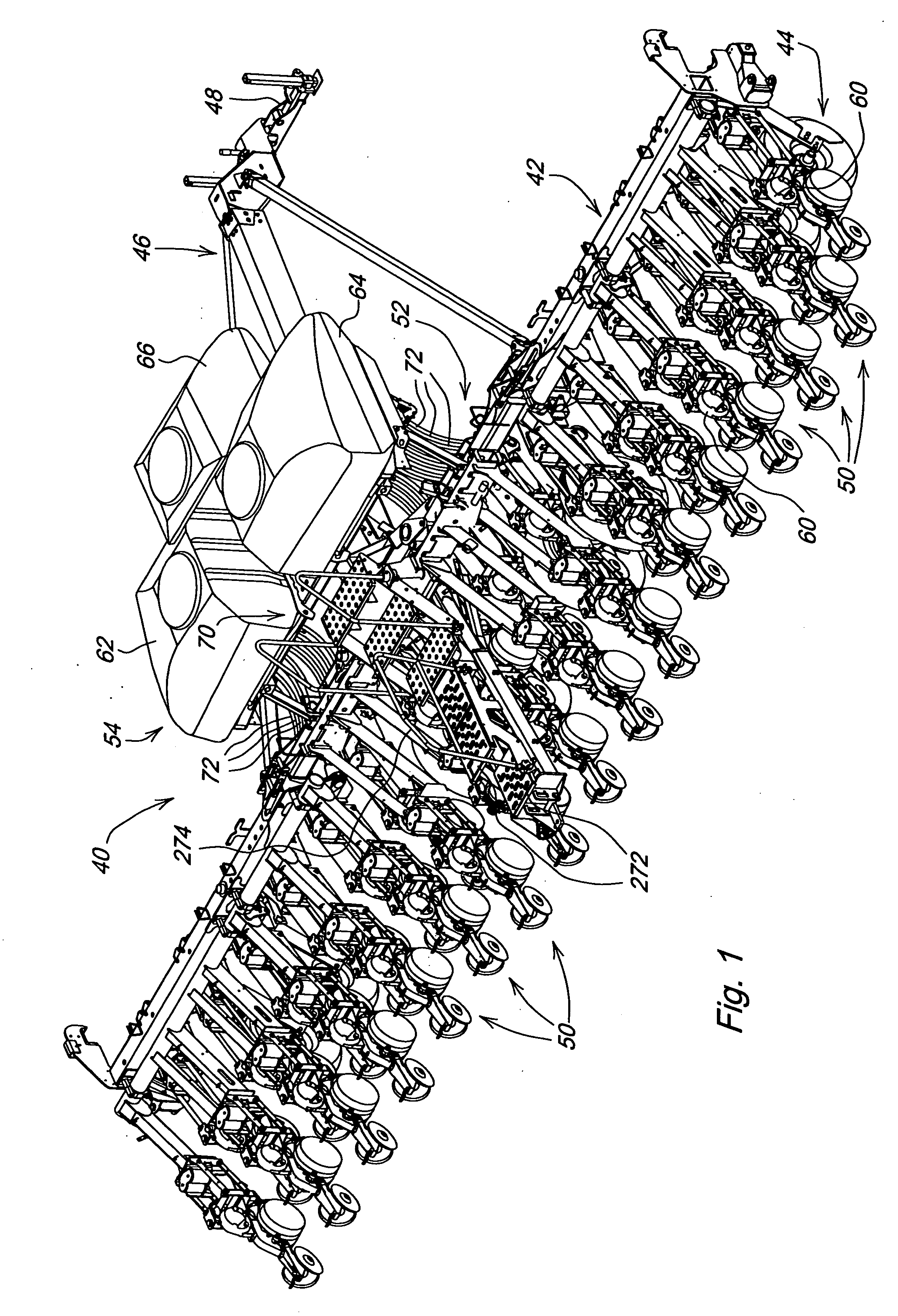

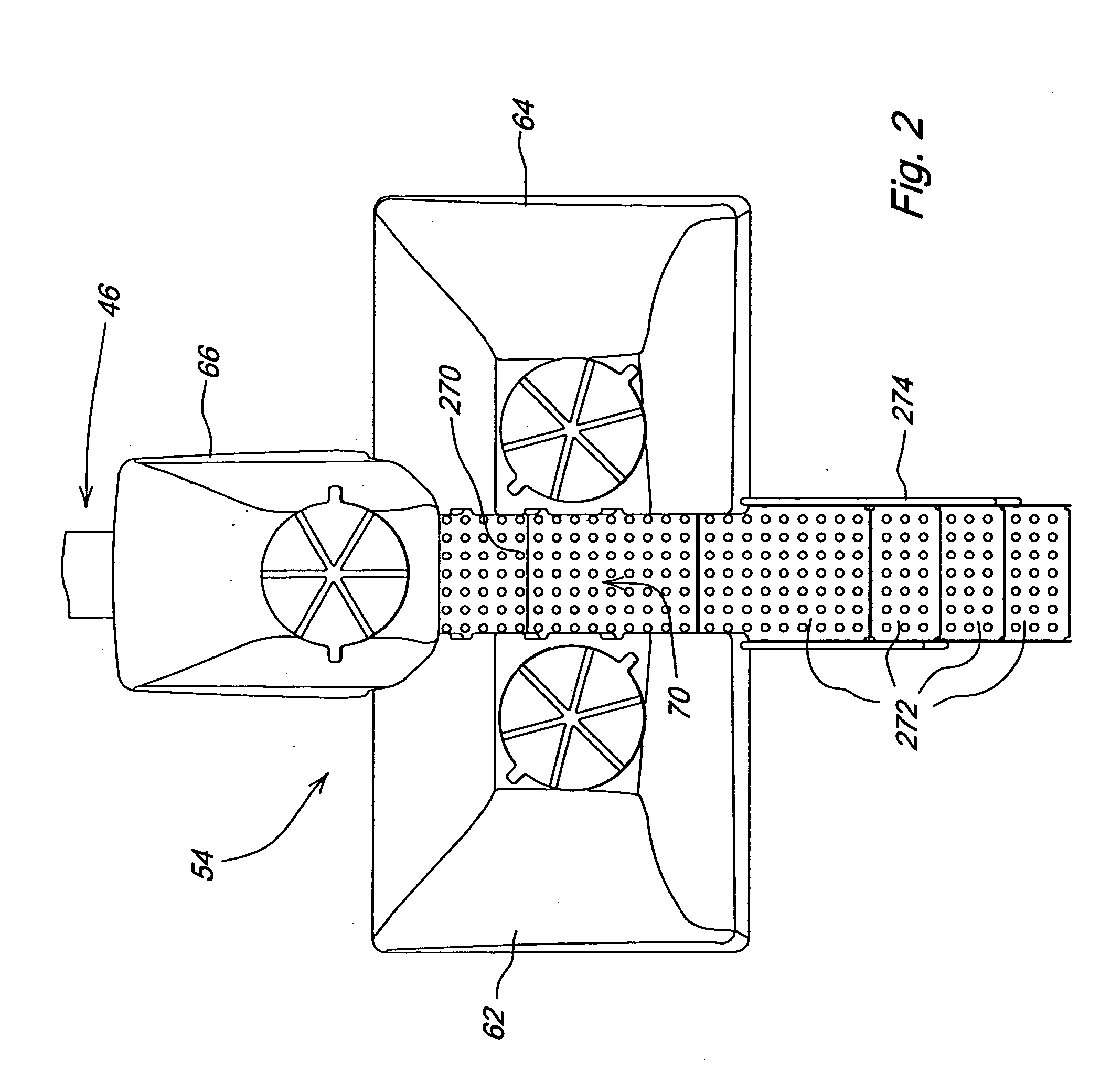

[0026] Referring now to FIG. 1, therein is shown a seeding implement 40 including a transversely extending main frame 42 supported for forward movement over the ground by lift wheel assemblies 44. A hitch 46 projects forwardly from the main frame 42 generally along a fore-and-aft machine centerline and includes a hitch connection 48 adapted for connection to a tractor or other towing vehicle (not shown). The frame 42 supports a plurality of transversely spaced row units or tools 50 connected through conduit structure 52 hopper structure 54 supported adjacent the hitch 46. One or more materials such as seed is delivered through the conduit structure 52 from the hopper structure 54 to the row units 50 for delivery to the soil. The row units 50 include meter housings or mini-hoppers 60 for receiving seed from the conduit structure 52. A seed on demand or similar system may be used to maintain the desired level of seed in the housings or hoppers 60.

[0027] The hopper structure 54 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com