Pegboard bracket assembly

a technology for pegboards and brackets, applied in the field of support brackets, can solve the problems of not having an existing pegboard display holder for products or promotional information, and achieve the effects of convenient adjustment, convenient manipulation and installation, and convenient securemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a detailed description of a preferred embodiment of the present invention and the best presently contemplated mode of its production and practice. This description is further made for the purpose of illustrating the general principles of the invention but should not be taken in a limiting sense, the scope of the invention being best determined by reference to appended claims.

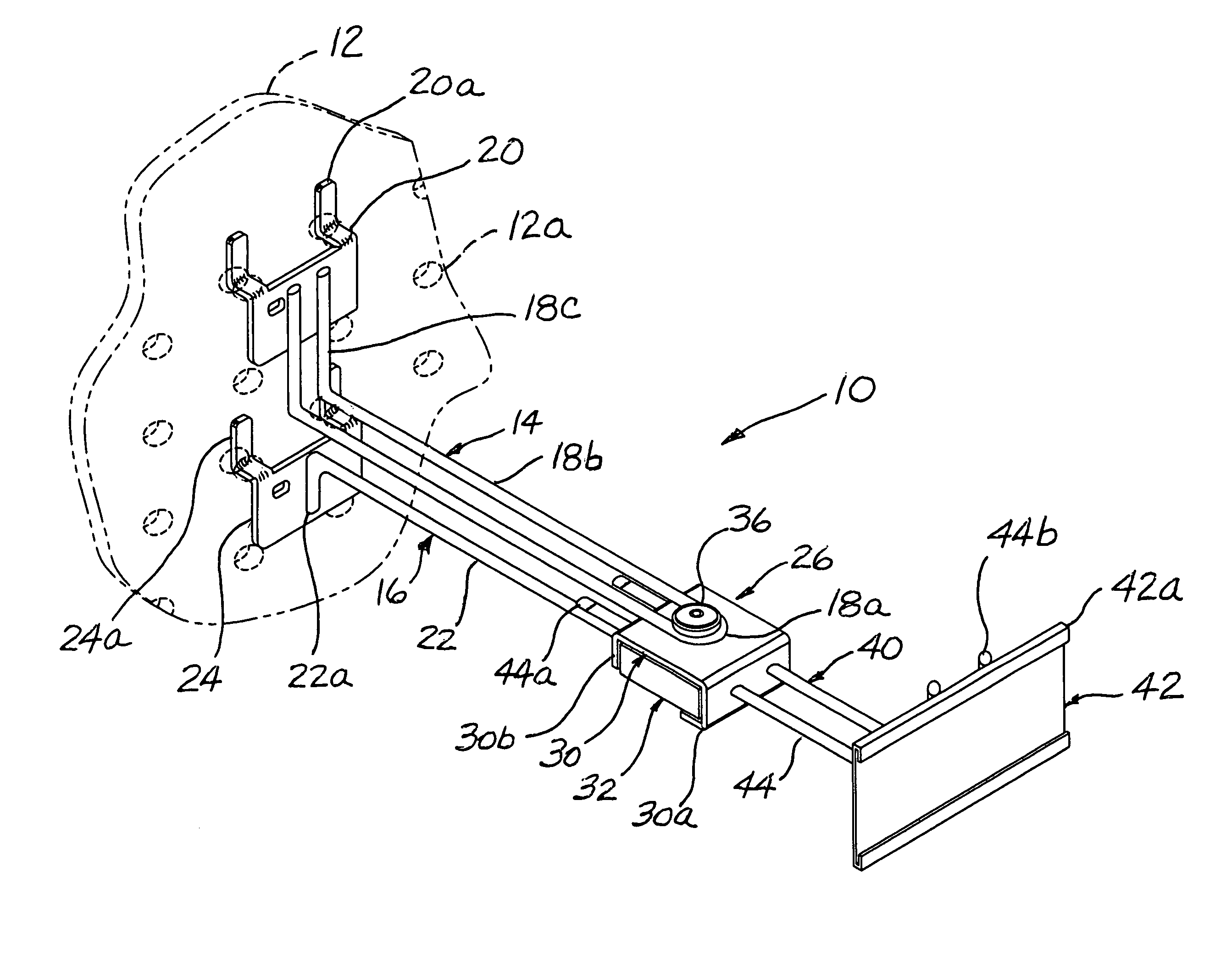

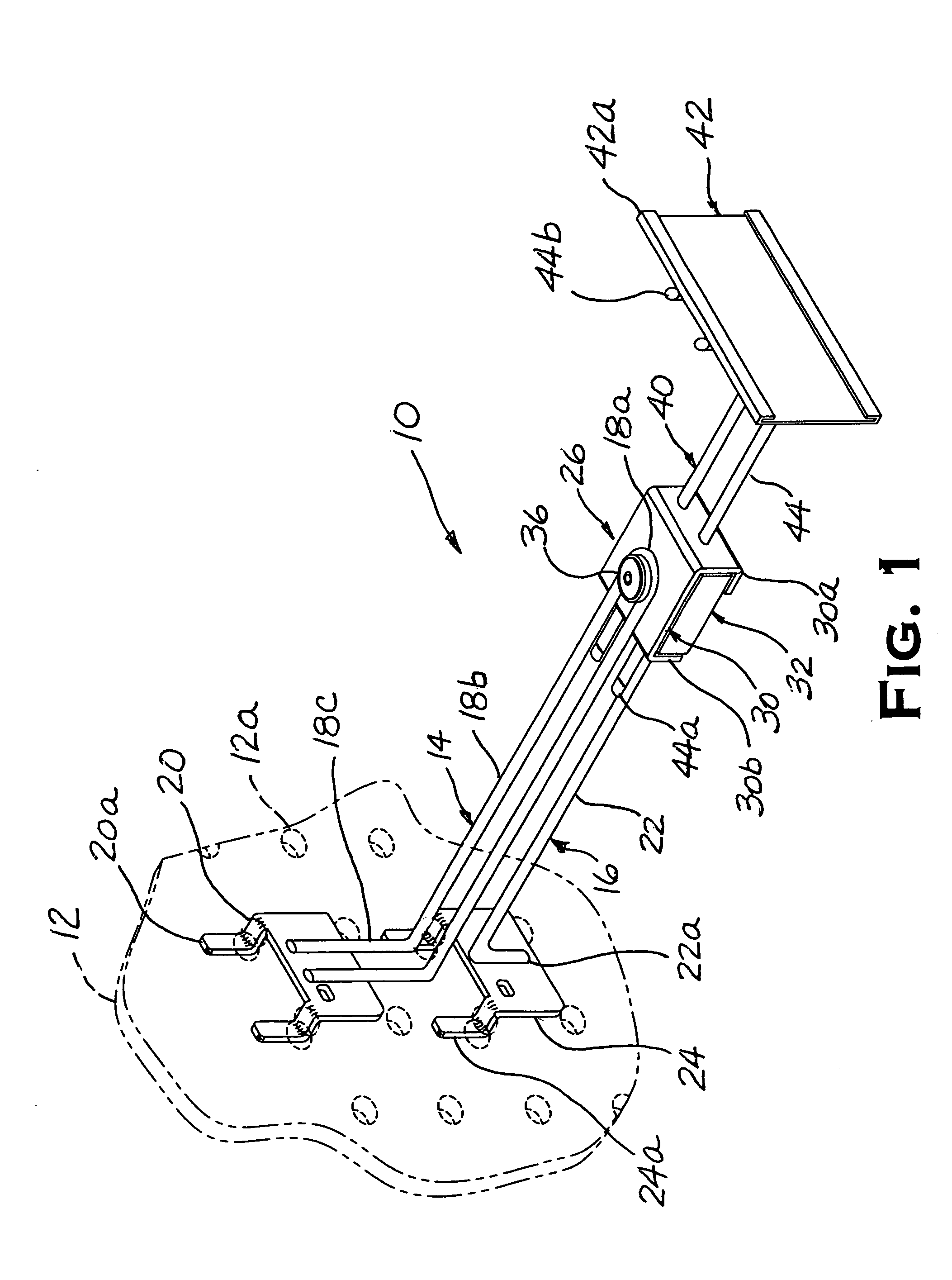

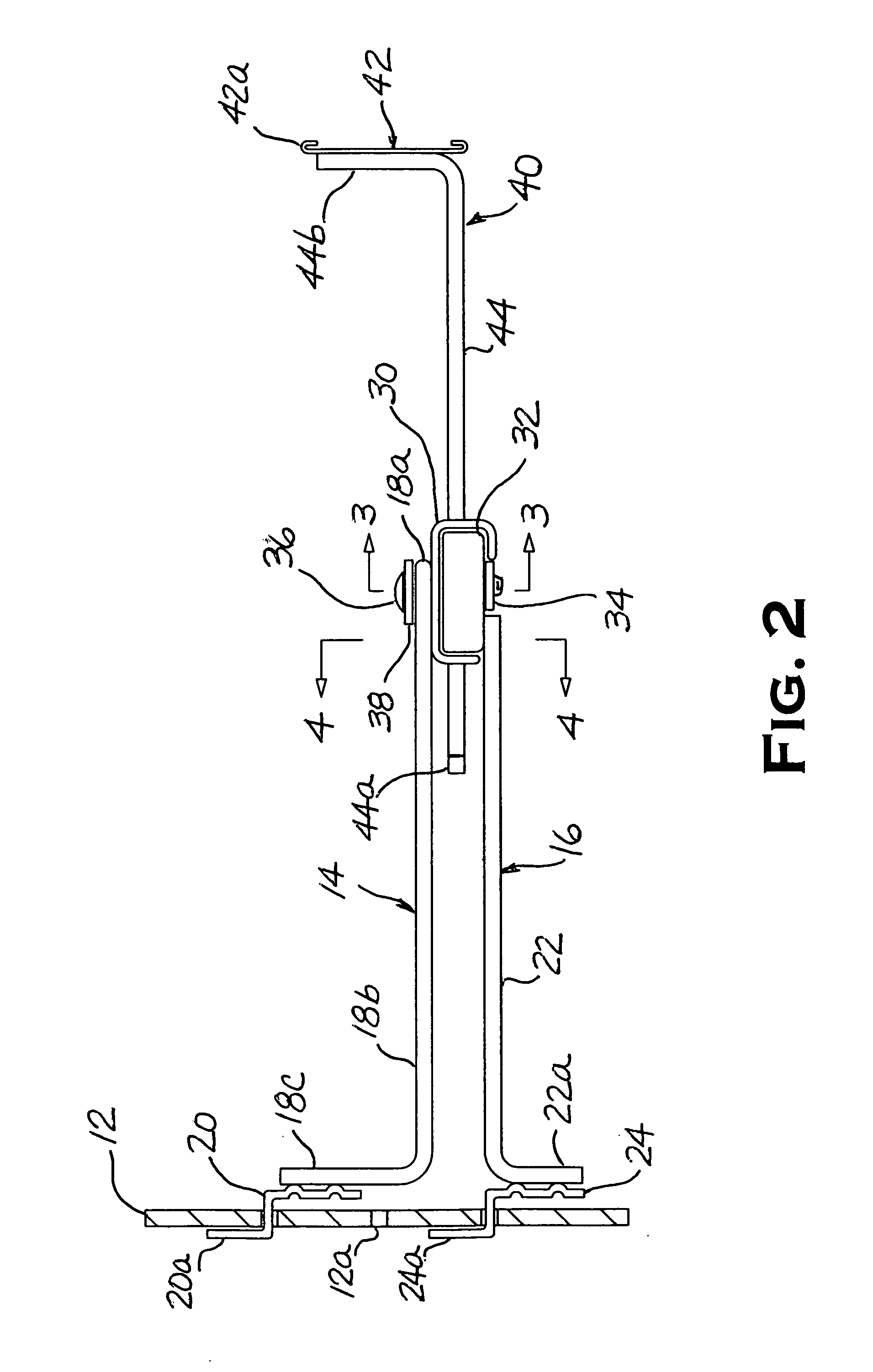

[0020] Referring now to the drawing figures and particularly to FIGS. 1 and 2, a bracket assembly made in accordance with the present invention and generally designated 10 is shown in mounted installation upon a conventional pegboard panel 12 (shown in phantom section) commonly used in retail merchandising displays. In its mounted installation, the present bracket assembly 10 is intended to engage selected holes 12a generally found in a matrix arrangement of horizontal rows and vertical columns on the pegboard panel 12 by means of a pair of pronged clips 20 and 24 that are attached at re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com