Saw blade angular adjustment device for a metal and wood cutting machine

a technology of angular adjustment and metal and wood cutting machines, which is applied in the direction of metal sawing equipment, metal working equipment, metal-working equipment, etc., can solve the problems of machine defects, scarcely acceptable oblique edges, waste of time and labor, etc., and achieve the effect of quick decision of angl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

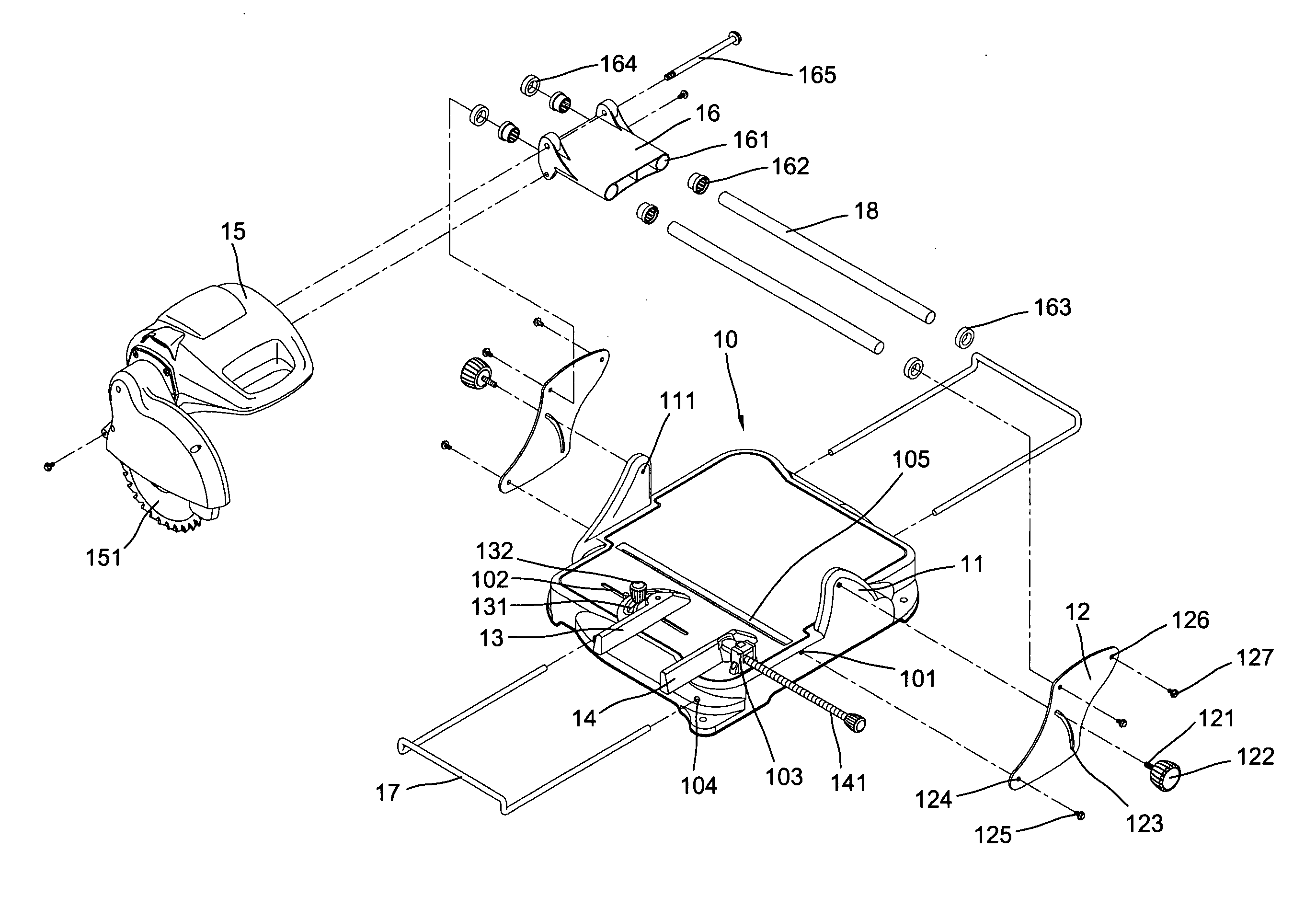

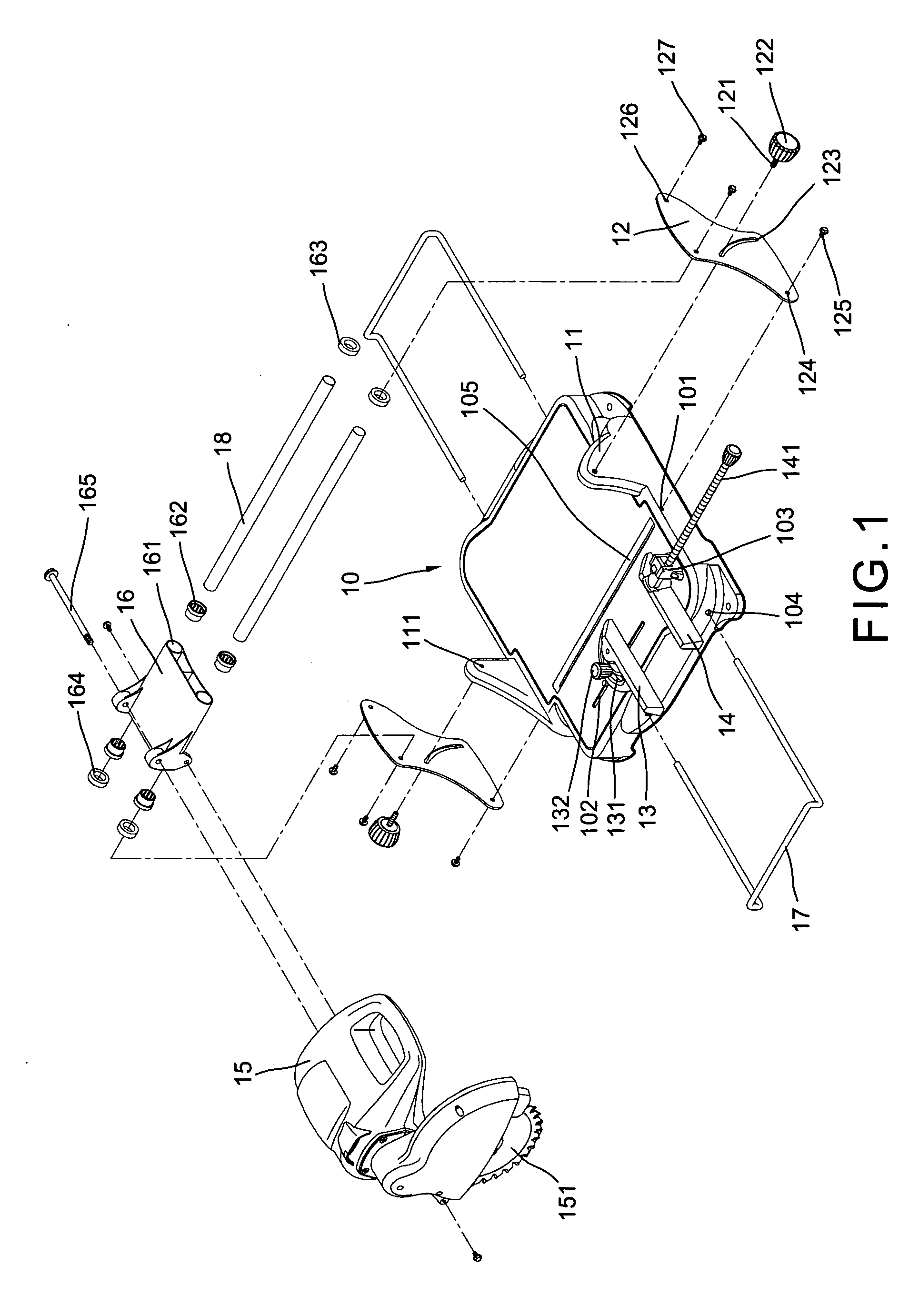

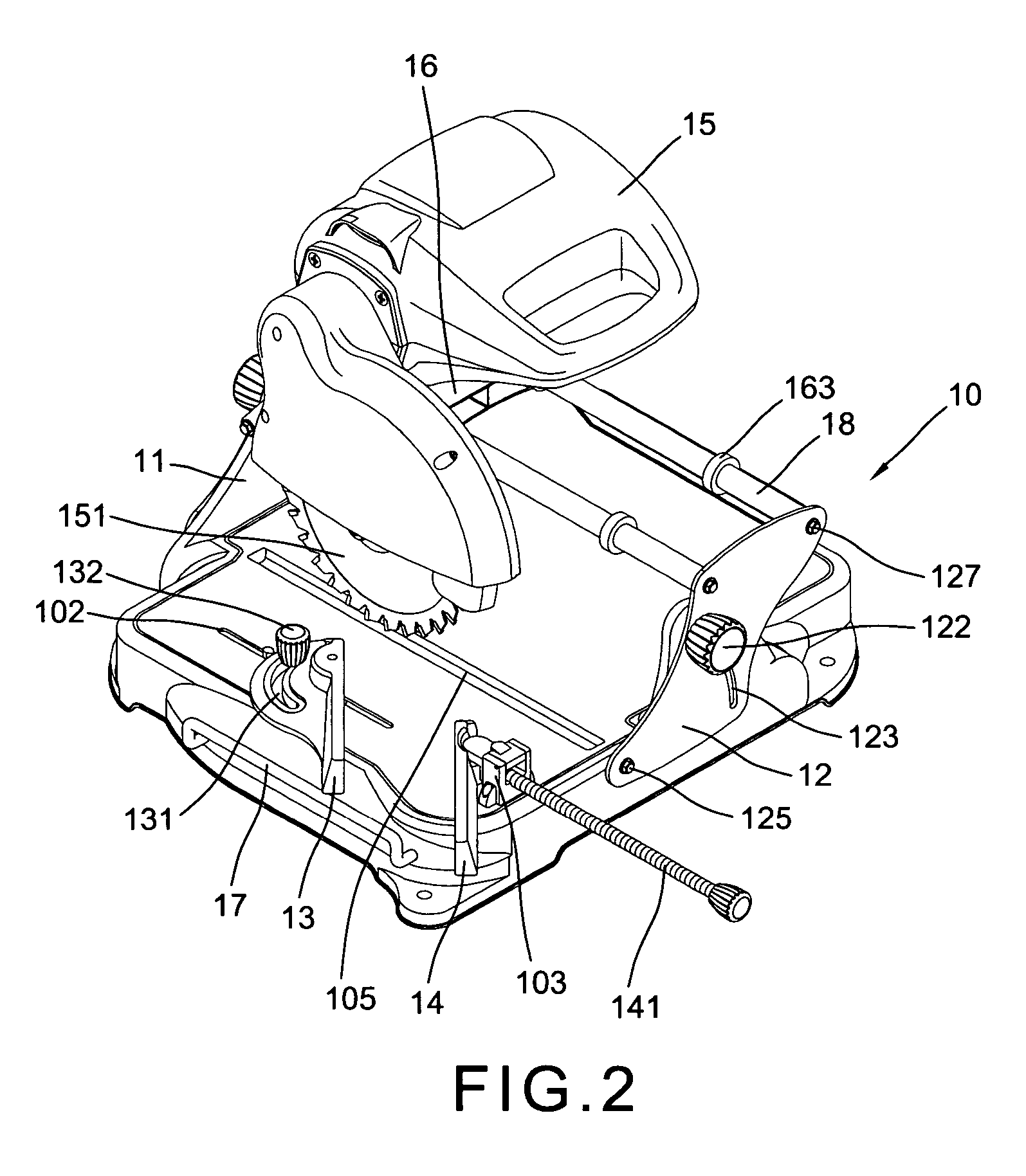

[0018] With reference to the drawings and initiated from FIGS. 1 to 4, the saw blade angular adjustment device for a metal and wood cutting machine of the present invention comprises a working platform 10 which has a pair of symmetrical triangular support arms 11 projected upward for two lateral edges each having a screw hole 111 adjacent the top for respectively fastening an arcuate slit 123 in the middle portion of a pair of pillow shaped pivotal plates 12 by threaded shanks 121 of the swivel buttons 122, a pair of clamping plate 13 and 14 movably and parallel disposed on a front top of the platform 10, a saw blade angular adjustment assembly 15 having a guarded saw blade 151 on one end, a displacement seat 16 on underside fastened by a long bolt 165 and a screw 161. The displacement seat 16 having a pair of tubes 161 in two lateral edges slidable on a pair of sliding bars 18 parallel connected to the top of the pair of the pillow shaped pivotal plates 12 by screws 127 through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com