LIF socket connector

a socket and socket technology, applied in the direction of coupling device connection, electrical apparatus construction details, engagement/disengagement of coupling parts, etc., can solve the problems of inconvenient pin insertion or removing of the corresponding spring arm, and insufficient flexibility of the whole contact. , to achieve the effect of convenient pin insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Reference will now be made to the drawings to describe the present invention in detail.

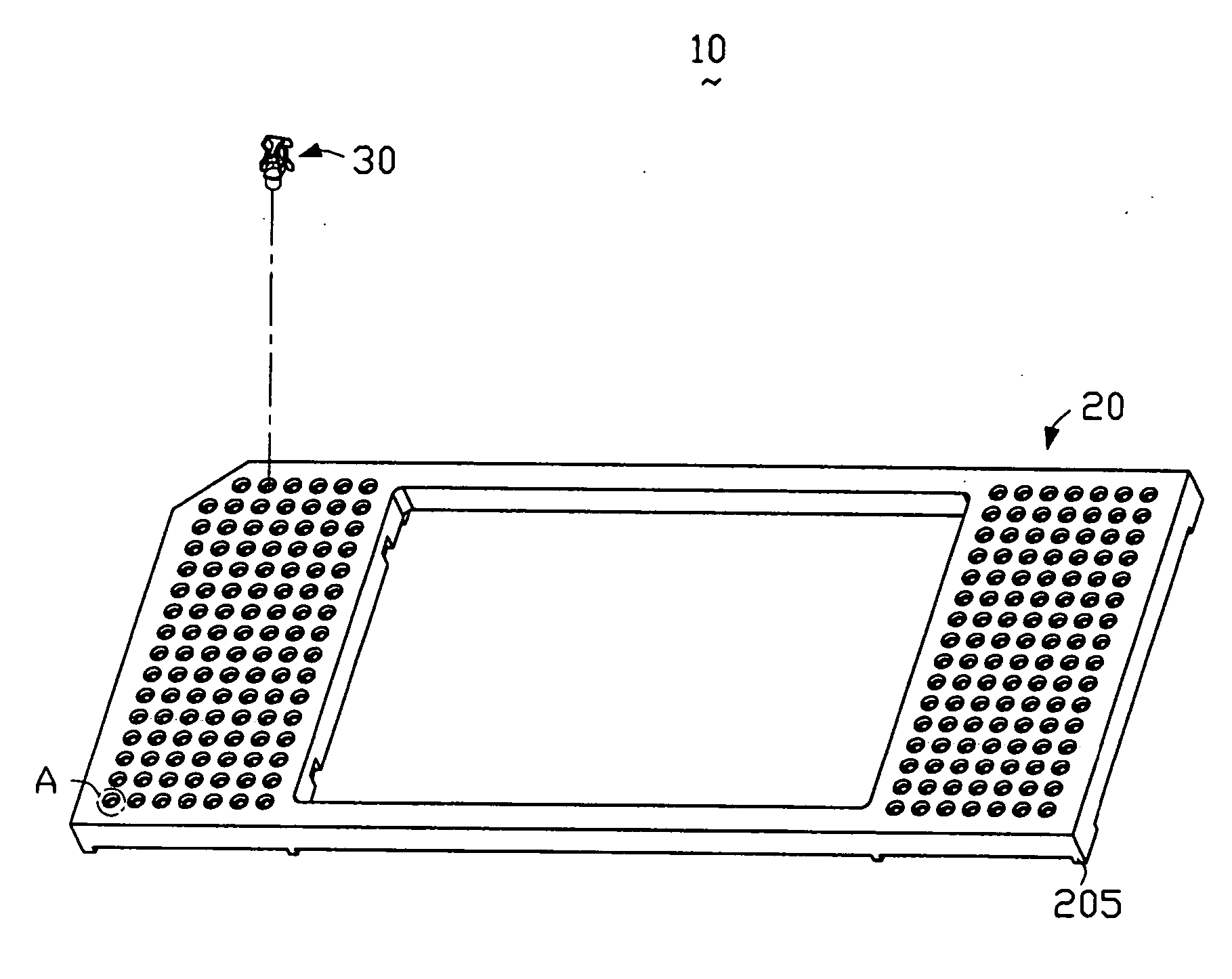

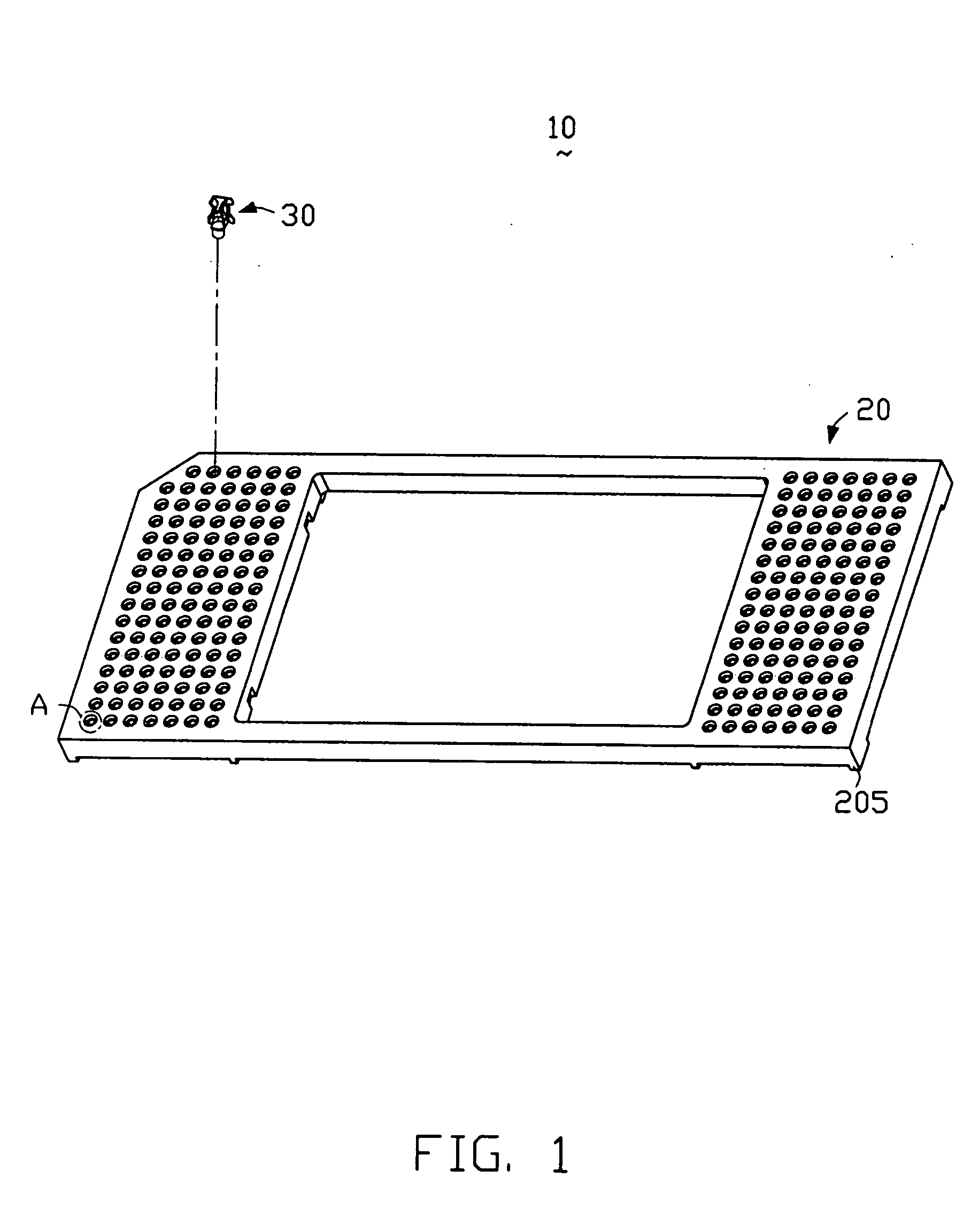

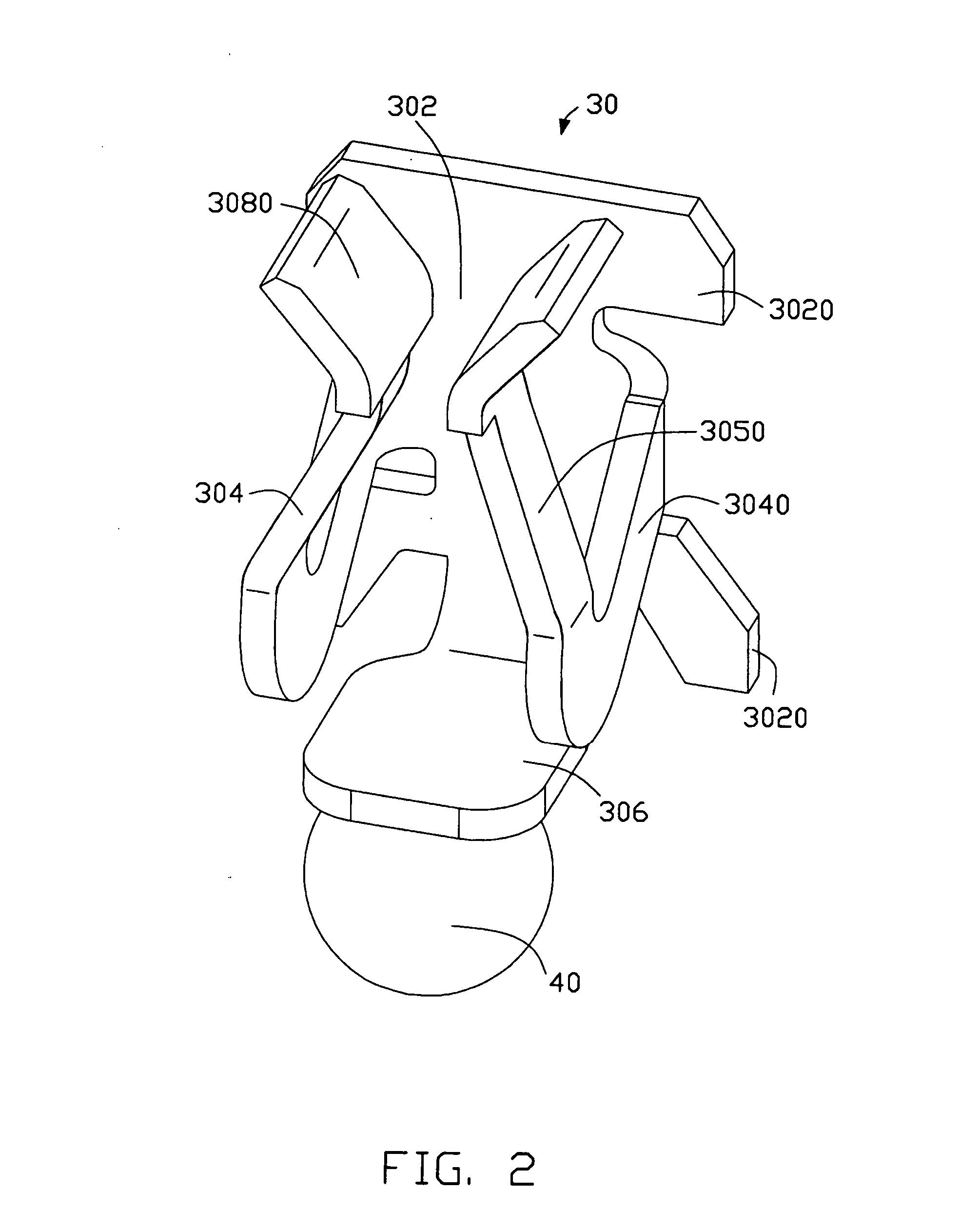

[0023]FIG. 1 is an assembled view of a LIF socket 10 for electrically connecting an IC package (not shown) and a PCB (not shown) in accordance with a preferred embodiment of the present invention. The socket 10 comprises a housing 20 and a plurality of contacts 30 received therein.

[0024] As indicated in FIGS. 1, 5 and 7, the housing 20 is made of insulating material and is rectangular. The housing 20 has a supporting surface 202 and a mounting surface 204 opposite to the supporting surface 202. A number of standoffs 205 is provided at four corners of the mounting surface 204 as no known for the purpose of subsequent soldering process.

[0025] A number of passages 206 extends from the mounting surface 204. Each passage 206 comprises a leading section 210, a connecting section 212, and a base section 208. The connecting section 212 is a circular aperture and a diameter thereof is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com