Connecting system for connecting the parts of a garment display device, and garment display device comprising the connecting system

a technology of connecting system and display device, which is applied in the direction of garments, furniture joining, application, etc., can solve the problems of insufficient retention of rods or pins, cracking or breaking of rim portions, and affecting so as to achieve the effect of substantially improving the stability of display devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

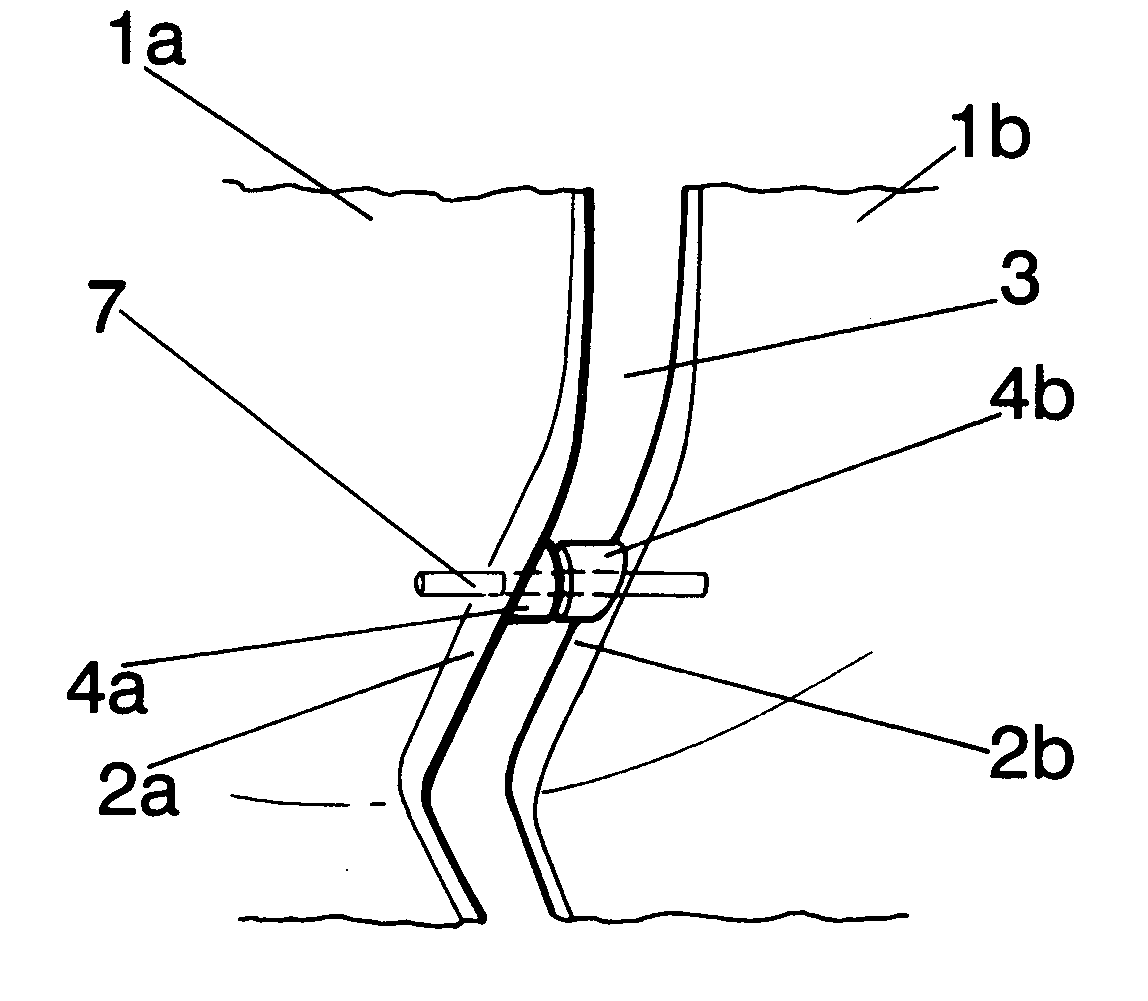

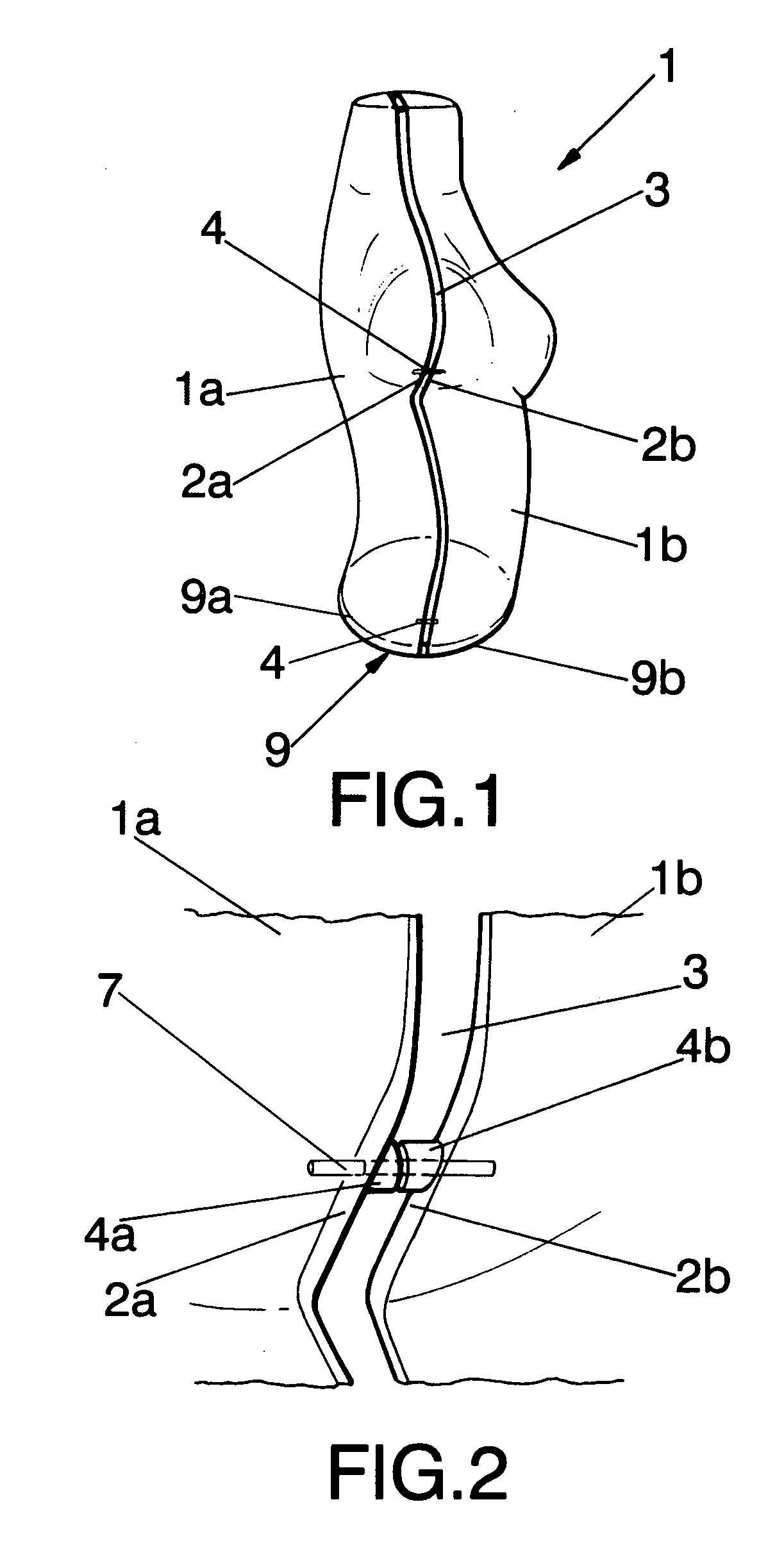

[0035]FIG. 2 is a more detailed view of the connection between the two parts of the torso represented in FIG. 1;

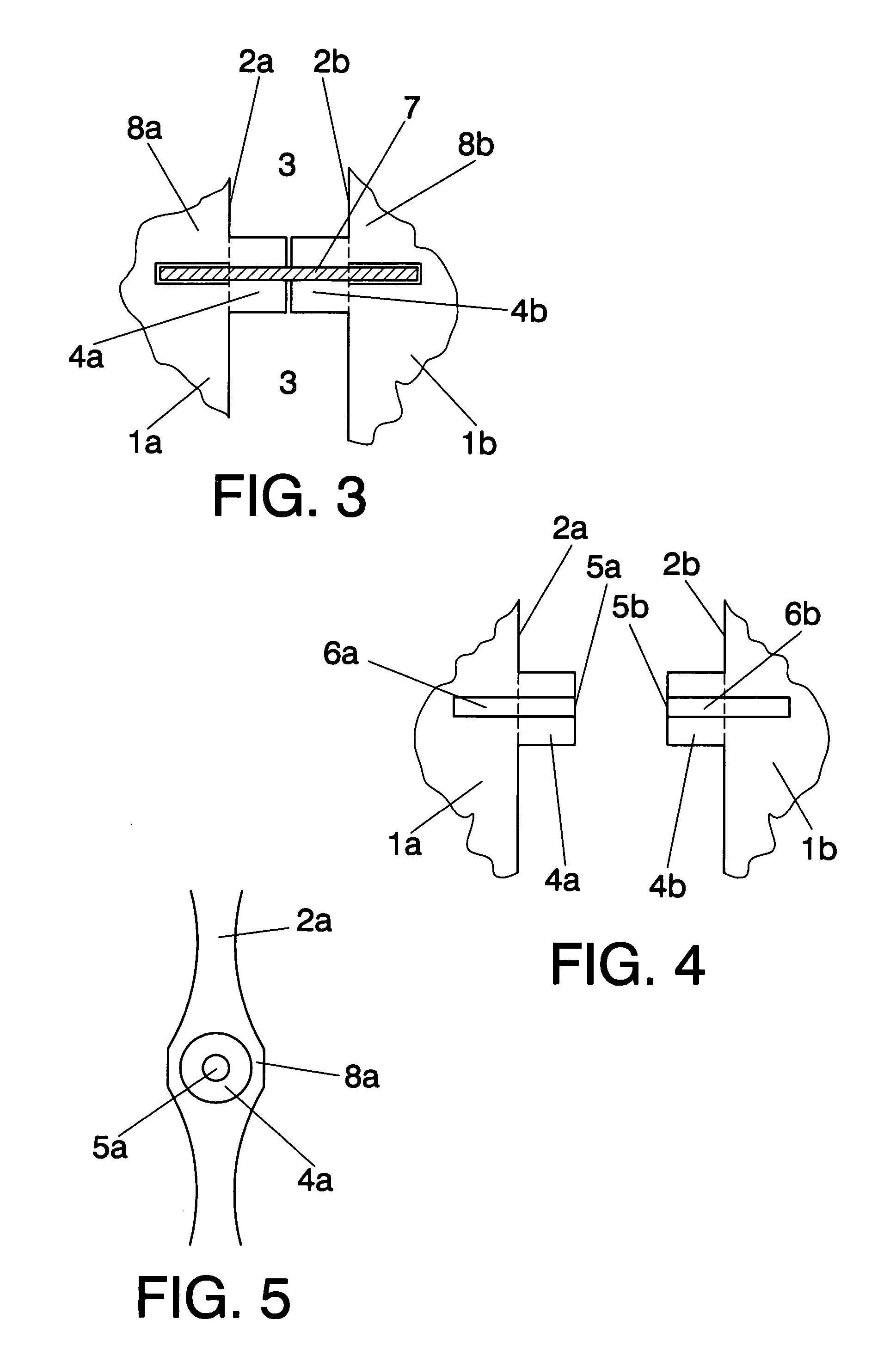

[0036]FIG. 3 is an enlarged front sectional view of the connection shown in FIG. 2;

[0037]FIG. 4 is a front sectional view corresponding to FIG. 3 but in which the hollow parts are unassembled and without the pin element shown in FIG. 3;

[0038]FIG. 5 is a side view from the left of the left rim portion shown in FIG. 4;

second embodiment

[0039]FIG. 6 is a front sectional view of the fastening means of the invention;

[0040]FIG. 7 is a front sectional view corresponding to FIG. 6 but in which the hollow parts are unassembled and without the pin element shown in FIG. 6;

[0041]FIG. 8 is a side view from the left of the left rim portion shown in FIG. 7;

[0042]FIG. 9 is a side view from the right of the right rim portion shown in FIG. 8;

third embodiment

[0043]FIG. 10 is a front sectional view of the fastening means of the invention;

[0044]FIG. 11 is a front sectional view corresponding to FIG. 10 but in which the hollow parts are unassembled and without the pin element shown in FIG. 10;

[0045]FIG. 12 is a side view from the left of the left rim portion shown in FIG. 11

[0046] The reference numerals appearing in these figures denote the following elements

[0047]1 garment display device

[0048]1a first part of the display device

[0049]1b second part of the display device

[0050]2a first perimetric rim portion

[0051]2b second perimetric rim portion

[0052]3 gap

[0053]4 fastening means

[0054]4a first projection

[0055]4b second projection

[0056]5a first opening

[0057]5b second opening

[0058]6a first internal hollow section

[0059]6b second internal hollow section

[0060]7 pin element

[0061]8a first reinforced area

[0062]8b second reinforced area

[0063]9 bottom portion of the display device

[0064]9a bottom portion of first part of the display d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com