Bracket and Method for Transport of Articulated Arm Attachment

a technology of articulated arm and bracket, which is applied in the direction of mechanical machines/dredgers, soil-shifting machines/dredgers, constructions, etc., can solve the problems of frequent dug up or damaged, similar ground damage, and large assistance and manipulation, and achieve the effect of reducing the operating weight of hydraulically operated machines, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Bracket 2 of the present invention is installable to any type of machine having an articulated arm. For ease of understanding, the figures of the following exemplar describes bracket 2 mountable to a hydraulically operated backhoe-front end loader articulated arm being used to transport a hydro hammer attachment. However, its use is not limited to this particular combination of machine and working end attachment.

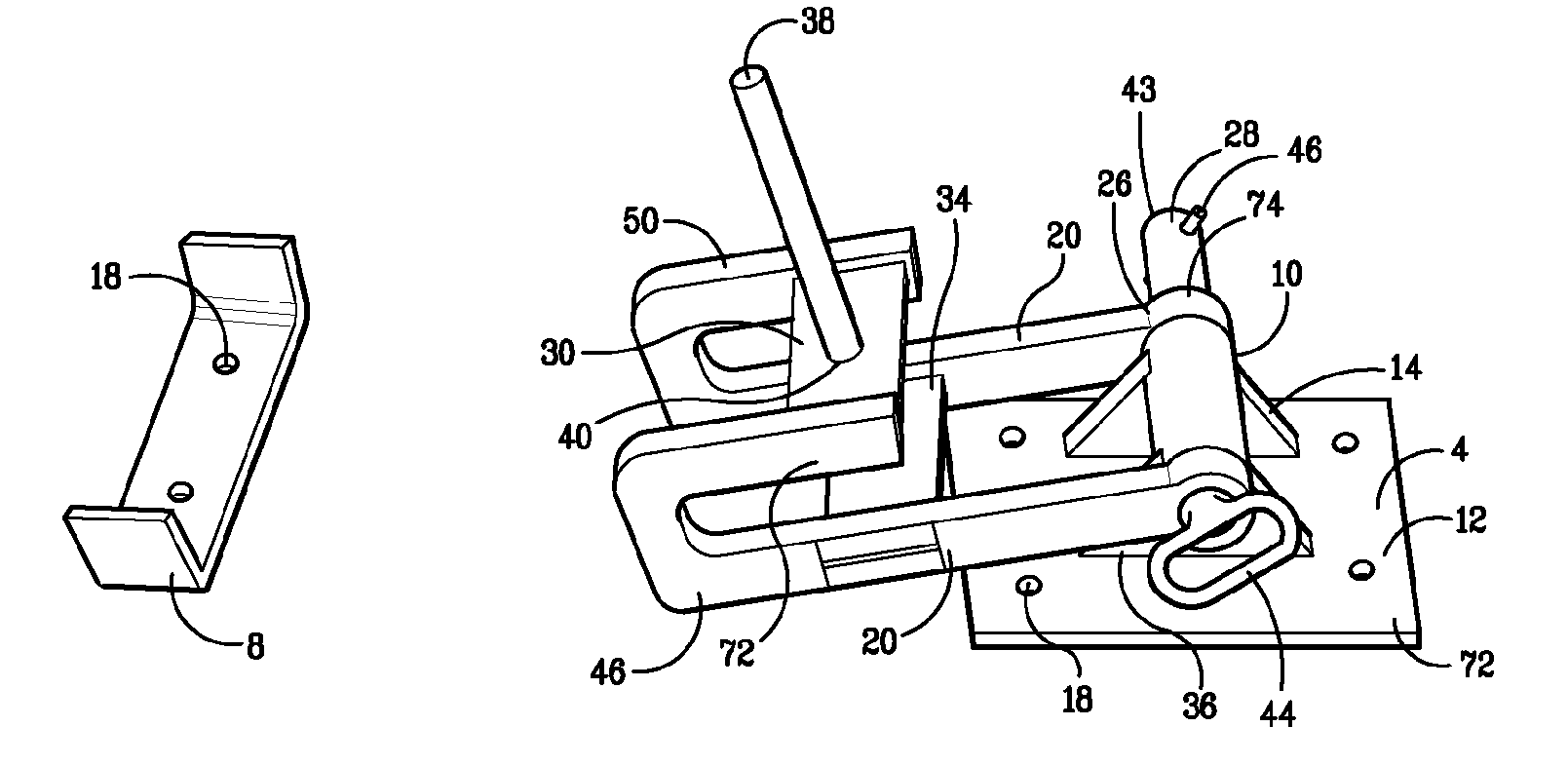

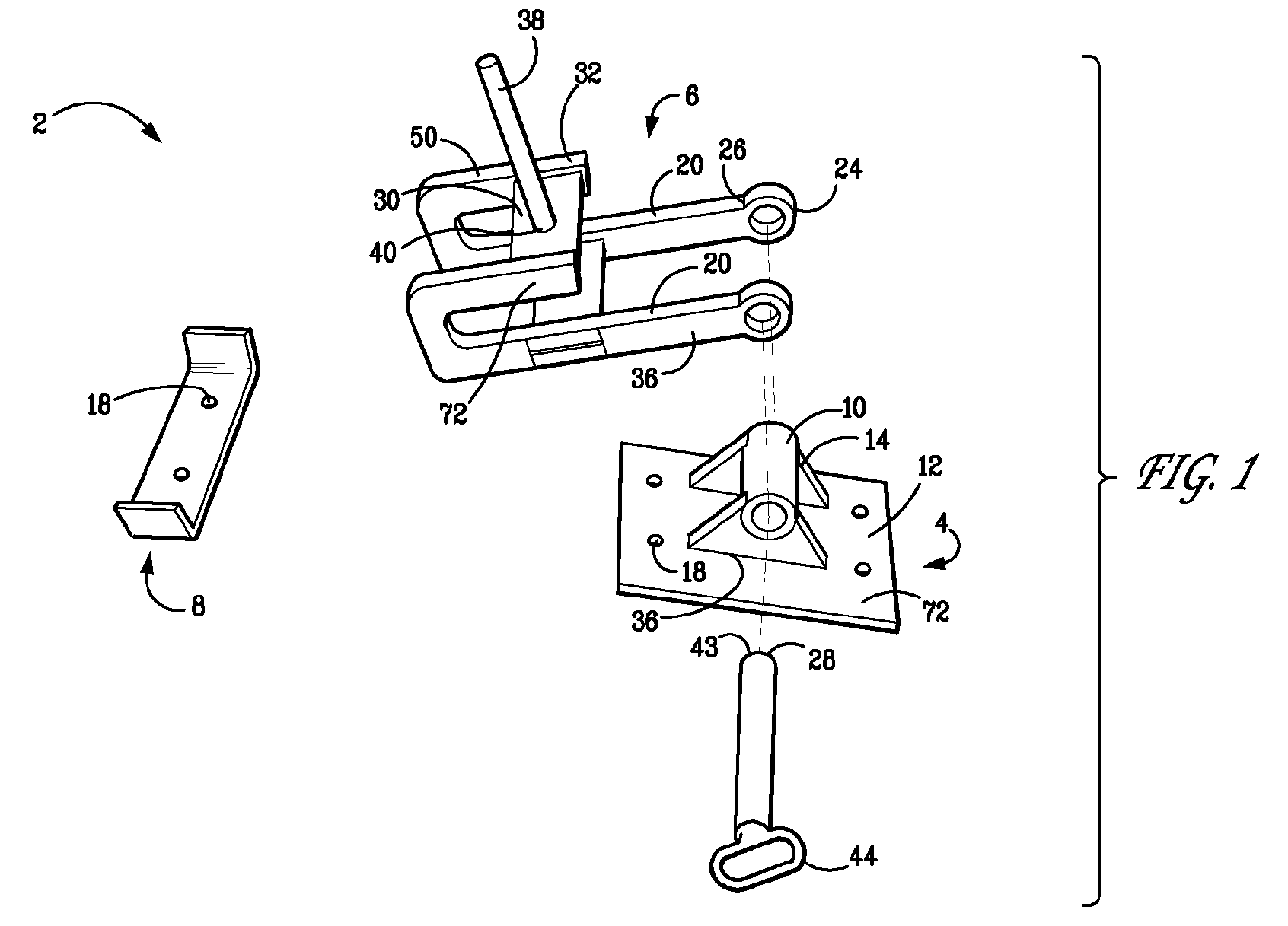

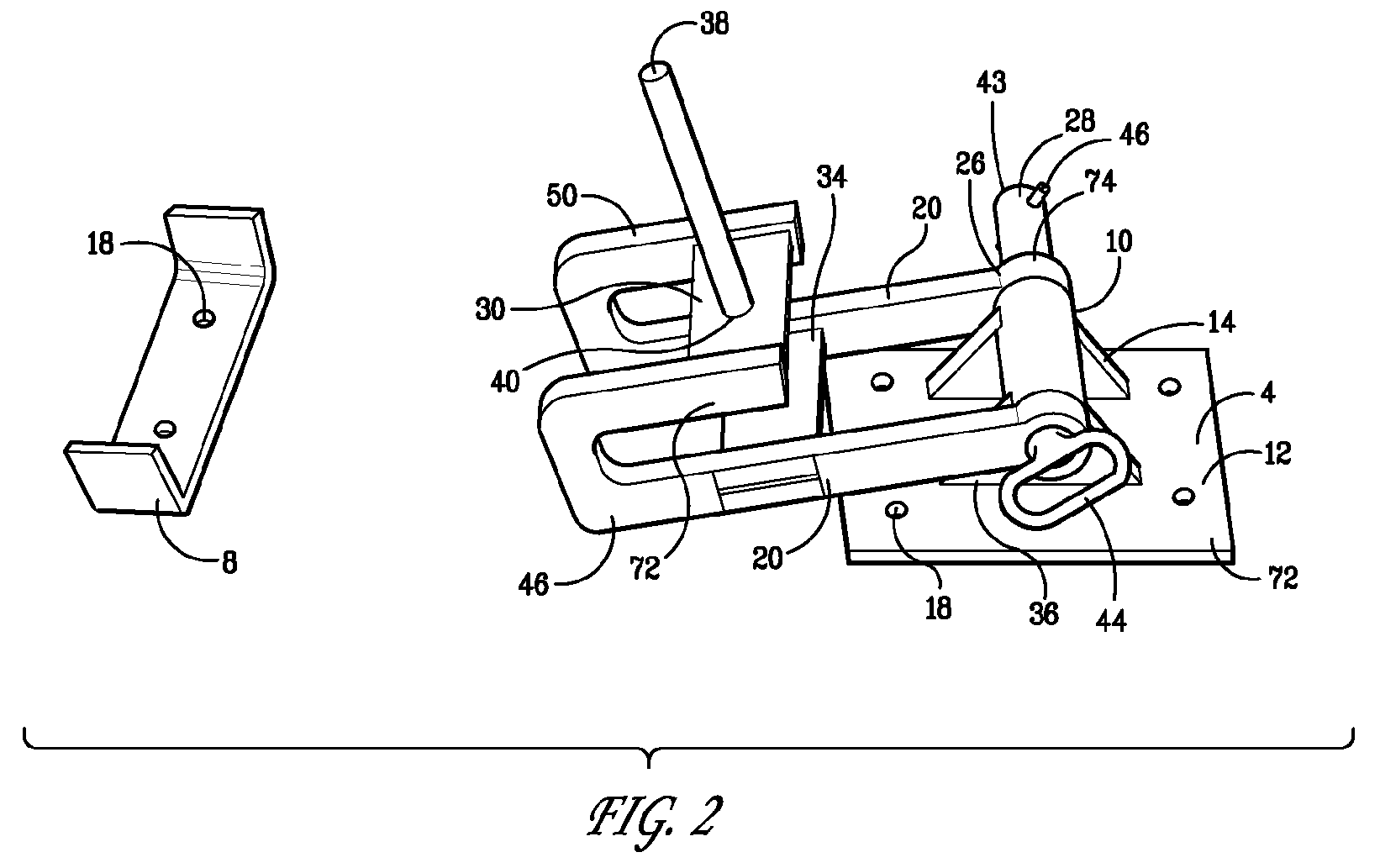

[0022] Turning now to FIGS. 1 and 2, bracket 2 comprises three major structural components: mounting assembly 4, pivot piece assembly 6, and optional stabilizer 8.

[0023] Mounting assembly 4, mounted to the underside of articulated arm 16 (FIG. 3), comprises cylinder 10. Although cylinder 10 may be mounted directly to articulated arm 16, in a preferred embodiment, mounting assembly 4 further comprises cylinder 10 mounted to plate 12, and most preferably, cylinder 10 is offset from plate 12 by at least one spacer 14. Optionally, at least one mounting orifice 18 is fab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com