Methods and apparatus for fastening panels

a technology of fastening panels and methods, applied in the directions of snap fasteners, buckles, transportation and packaging, etc., can solve the problem of not using additional structural footprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

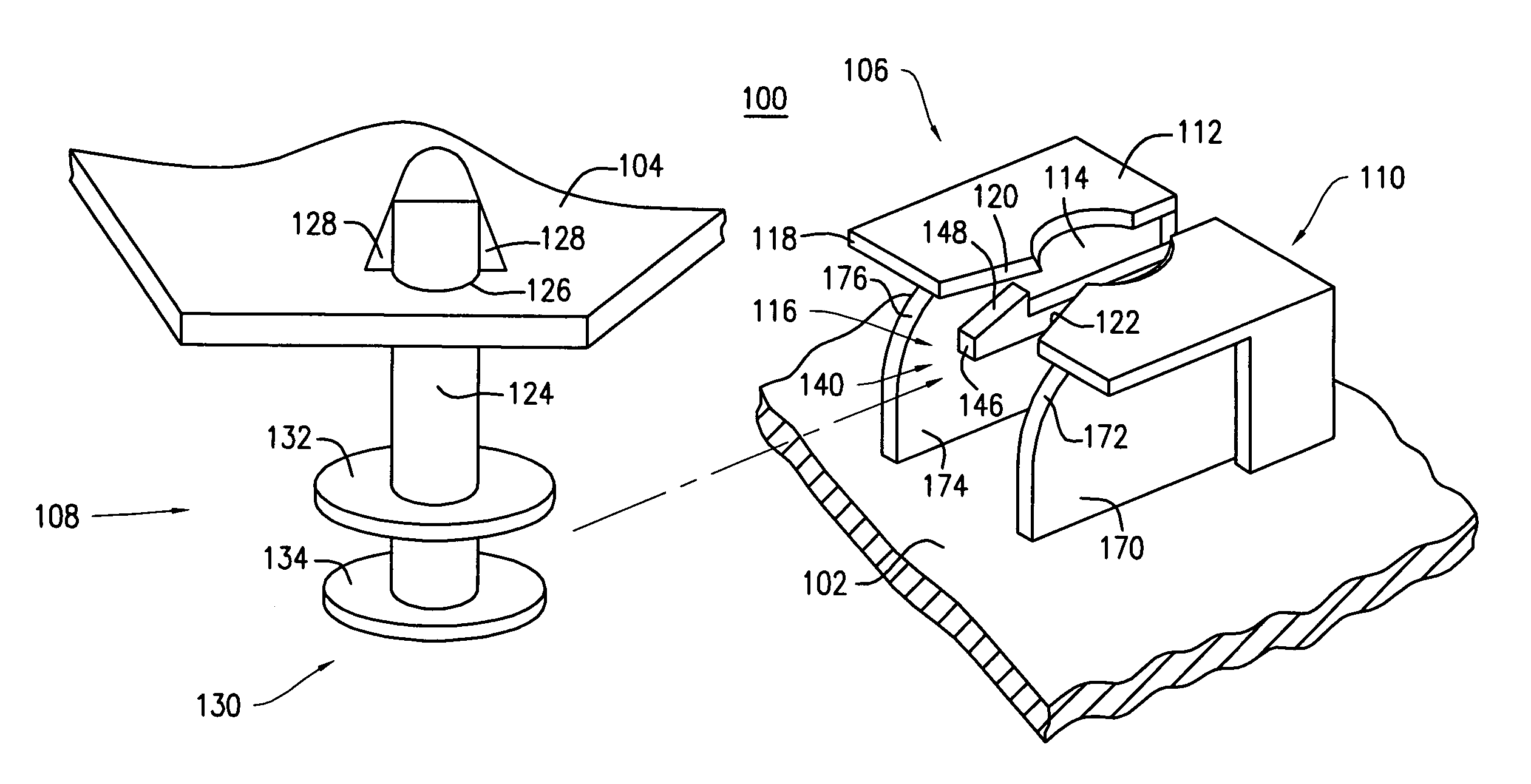

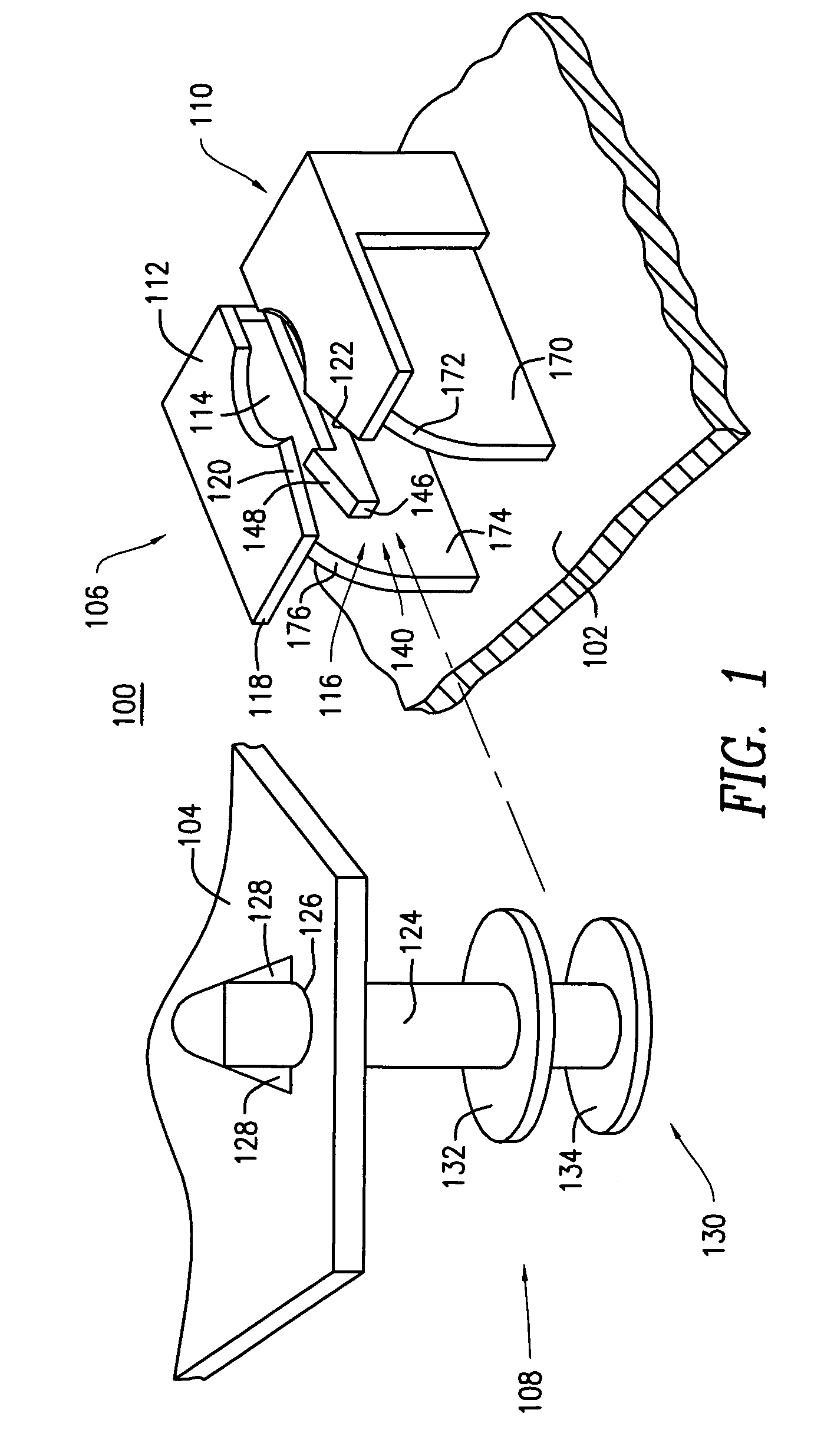

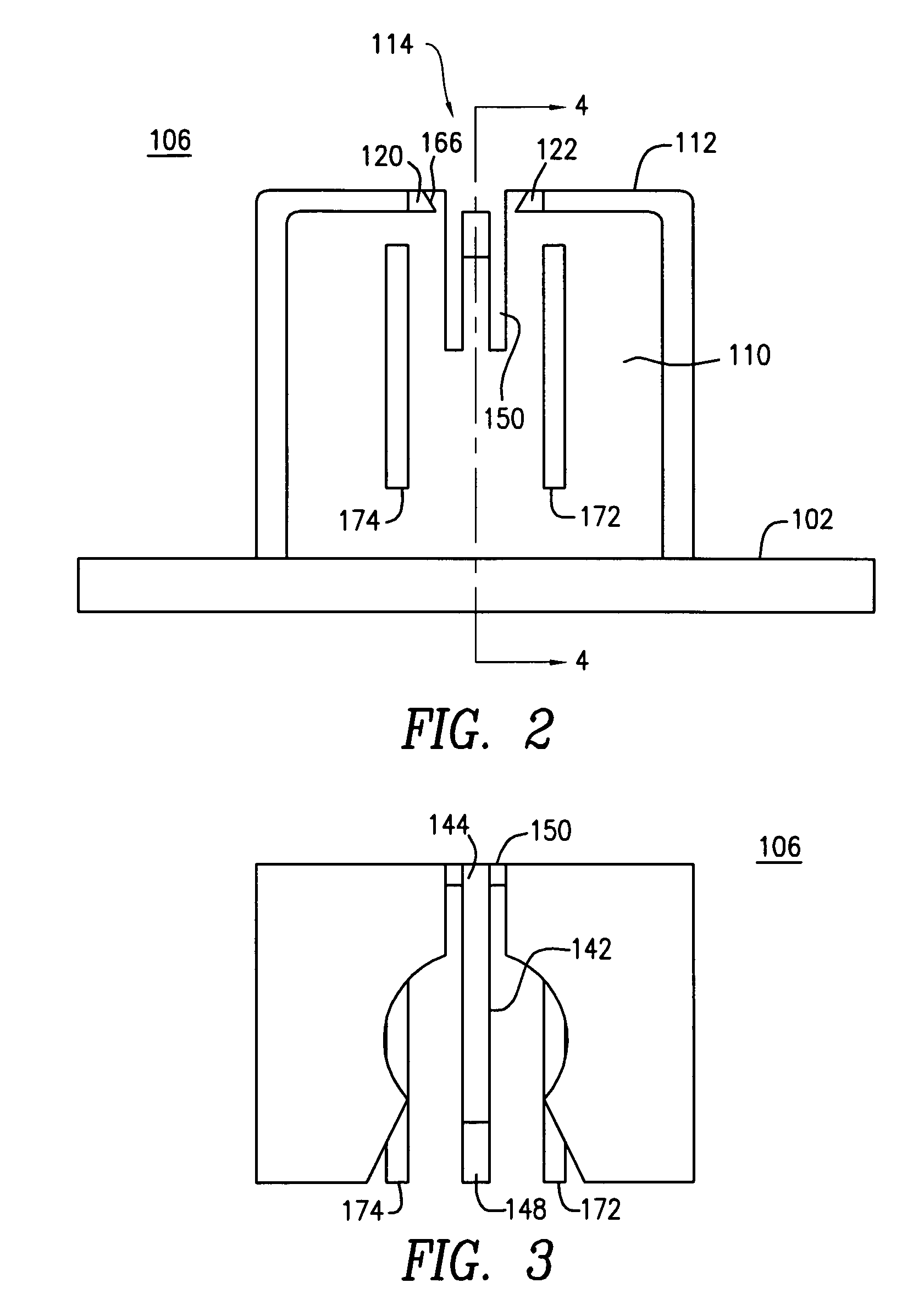

[0026] With reference to the drawings, wherein like numerals indicate like elements, there is shown in FIG. 1 a perspective view of a fastening system 100 for connecting a panel 102 to a frame 104 in accordance with one or more embodiments of the present invention. It will be appreciated by those skilled in the art that the panel 102 and frame 104 may be employed in any number of different mechanical contexts. By way of example, and not by limitation, the panel 102 may be a door trim panel 102 for the interior of an automobile and the frame 104 may be the door module 104 of the automobile to which the panel 102 is to be secured. The door module 104 preferably represents one or more structural elements of the door of a vehicle and the door trim panel 102 represents an aesthetically pleasing panel that covers the less aesthetically pleasing components of the door module 104. The door trim panel 102 is preferably coupled to the door module 104 by way of one or more fastening systems 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com