Adaptive control system having hedge unit and related apparatus and methods

a technology of adaptive control system and hedge unit, applied in adaptive control, process and machine control, instruments, etc., can solve the problems of affecting the adaptive control system, reducing the control response of adaptive control system, and causing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As used herein, the following terms have the following definitions:

[0023]“Actuator” can be virtually any device capable of affecting the state of a plant to control a degree of freedom thereof. Such actuator can be a motor, motor-driven screw, a hydraulic cylinder, a pump or valve controlling a stream of air, a thermal heater, a compressor or suction generator, or other device.

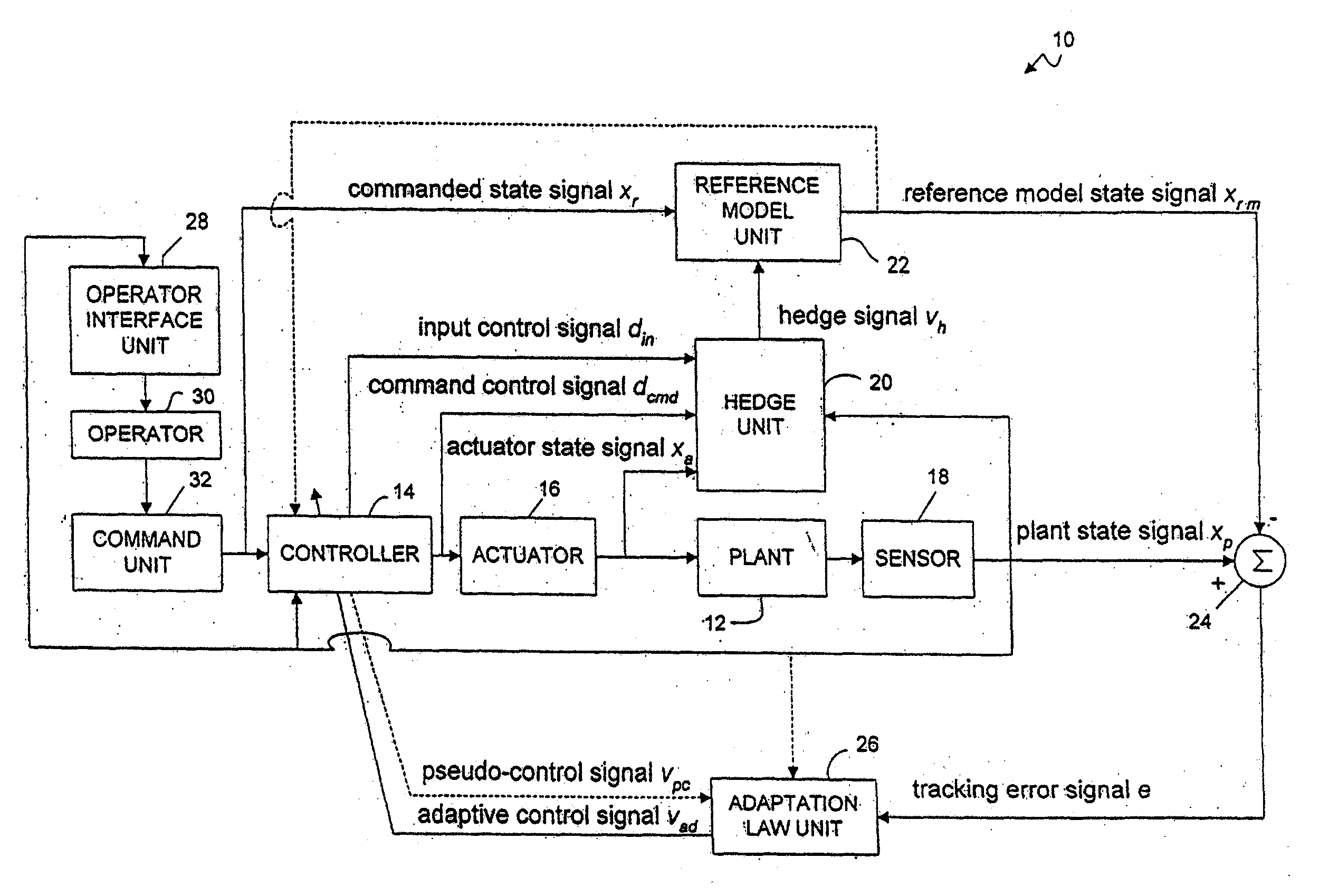

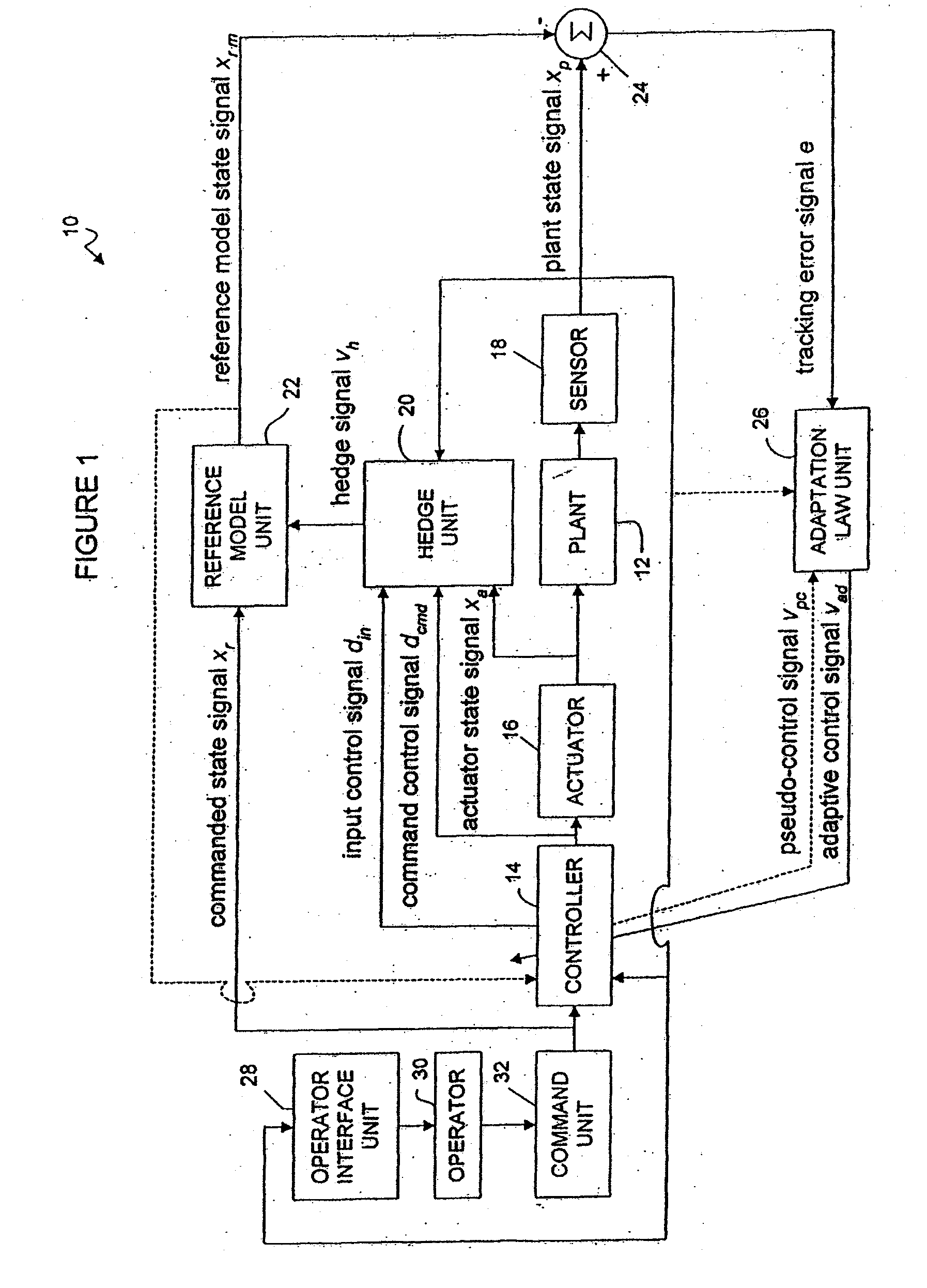

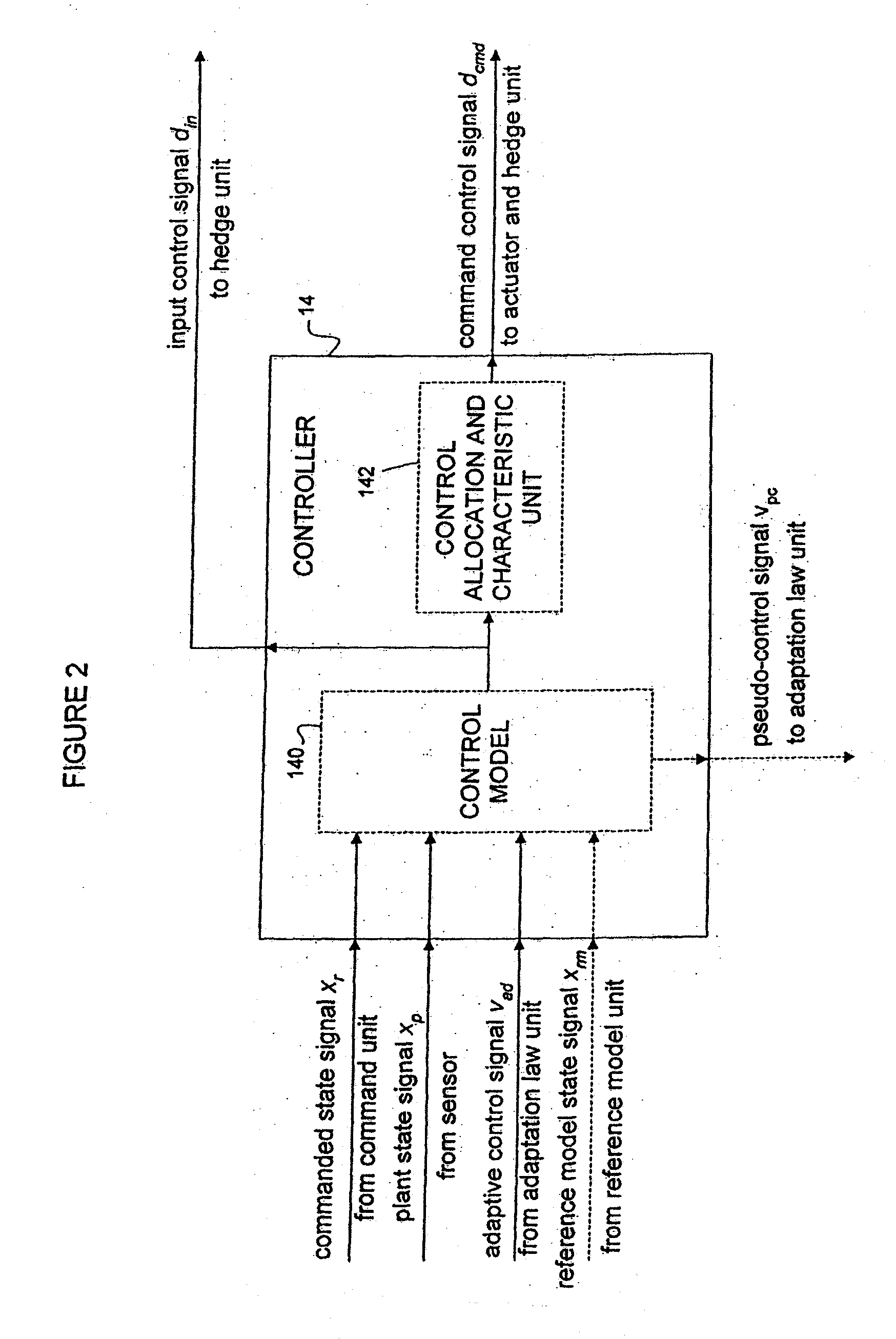

[0024]“Adaptive control system” means a control system having the capability to adapt to changes in a controlled plant or its environment over time.

[0025]“Characteristic” is a property of a plant or control system that has an effect for which adaptation of the control system is not to be performed. The characteristic can be a time delay between generation of a command signal and sensing and report of the plant state resulting from the command signal to the control system. The characteristic can also be a control limit such as actuator end points, e.g., extreme positions, temperatures, pressures, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com