Inflatable packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

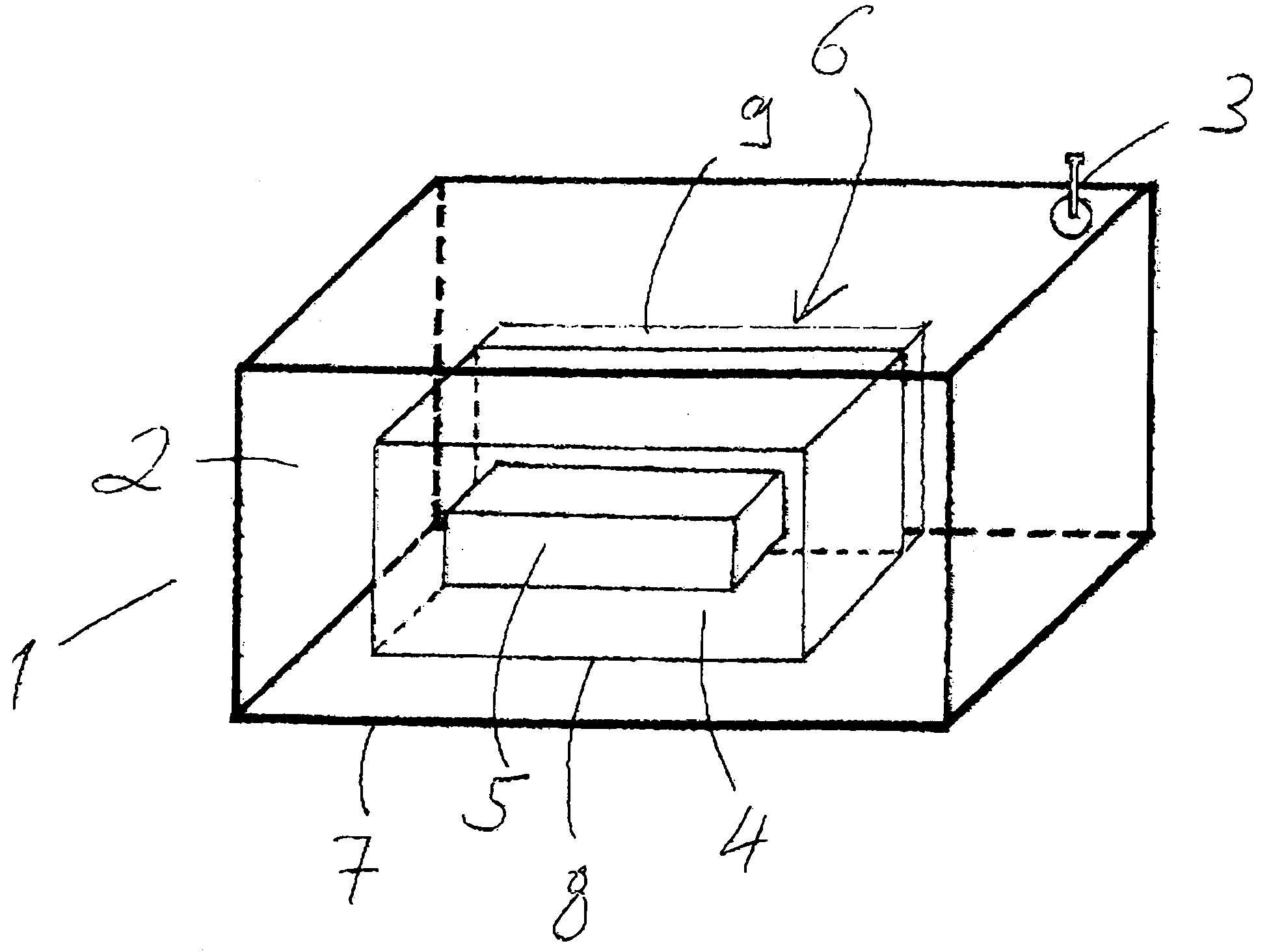

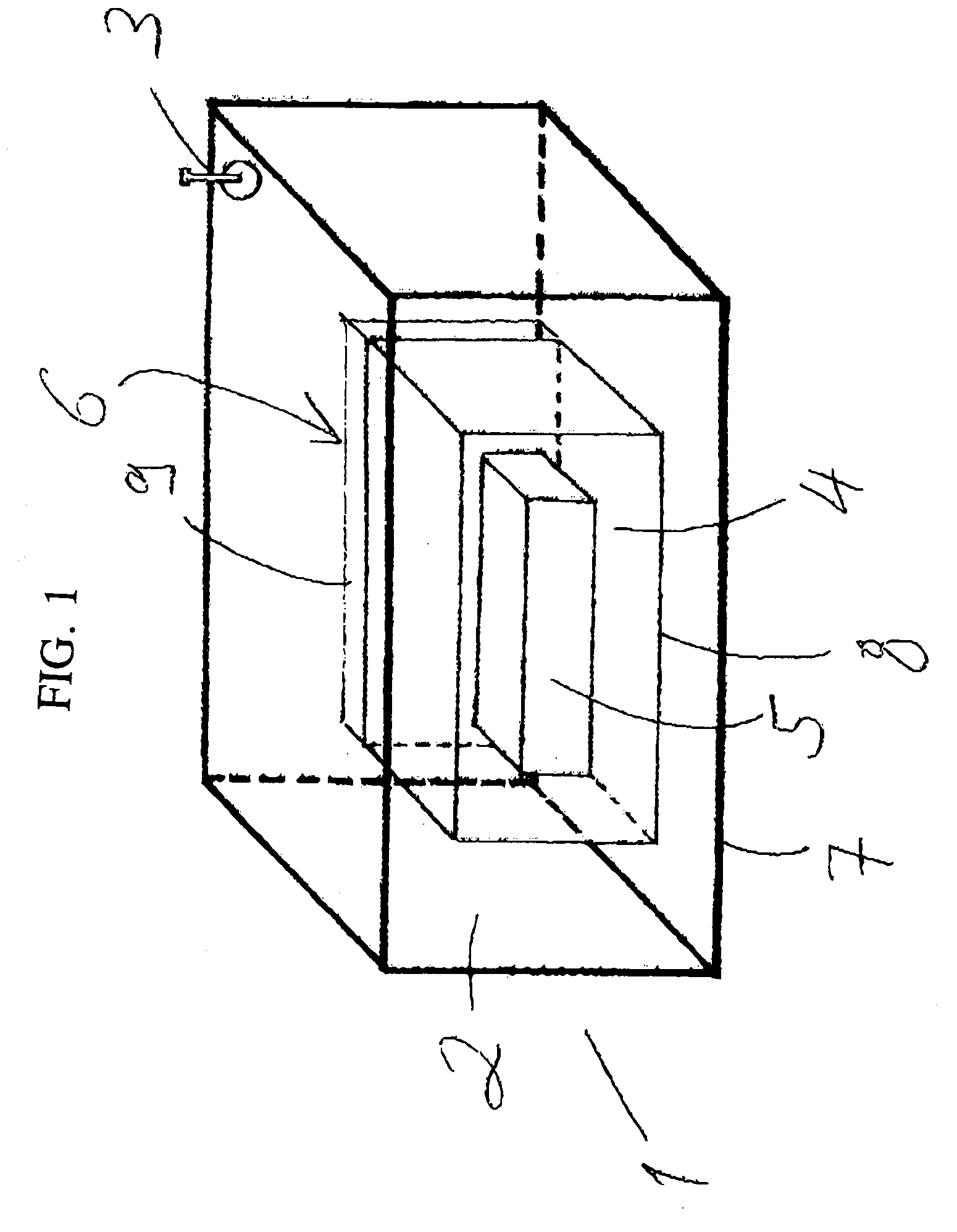

[0024]FIG. 1 is a three-dimensional view of a packaging 1, which has an outer cover 7 with a quadratic shape and a packaging space limitation 8, also with a quadratic shape, which between them envelop a gas space 2.

[0025]Both the outer cover 7 and the packaging space limitation 8 are formed from a transparent, flexible plastic film, which can be folded flat in the uninflated state. In the inflated state, a gaseous medium (e.g., air) is filled into the gas space 2 through a valve 3, such that the outer cover 7 as well as the packaging space limitation 8 are placed into an elongated state, which imparts adequate stability to the entire packaging 1. For this purpose, the pressure in the gas chamber 2 may be adjusted to requirements. The valve 3 ensures that no pressure loss occurs.

[0026]Both the outer cover 7 and the packaging space limitation 8 are connected together from cut-to-size plastic film or have been accordingly made in a casting or injection molding method, such that they ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap