Process for manufacturing insulated siding

a technology of insulating siding and manufacturing process, which is applied in the field of construction/wall covering art, can solve the problems of affecting the overall thermal properties of the building, and insulating vinyl or metal siding has very little insulative properties, so as to achieve the effect of easy manufacturing of siding products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

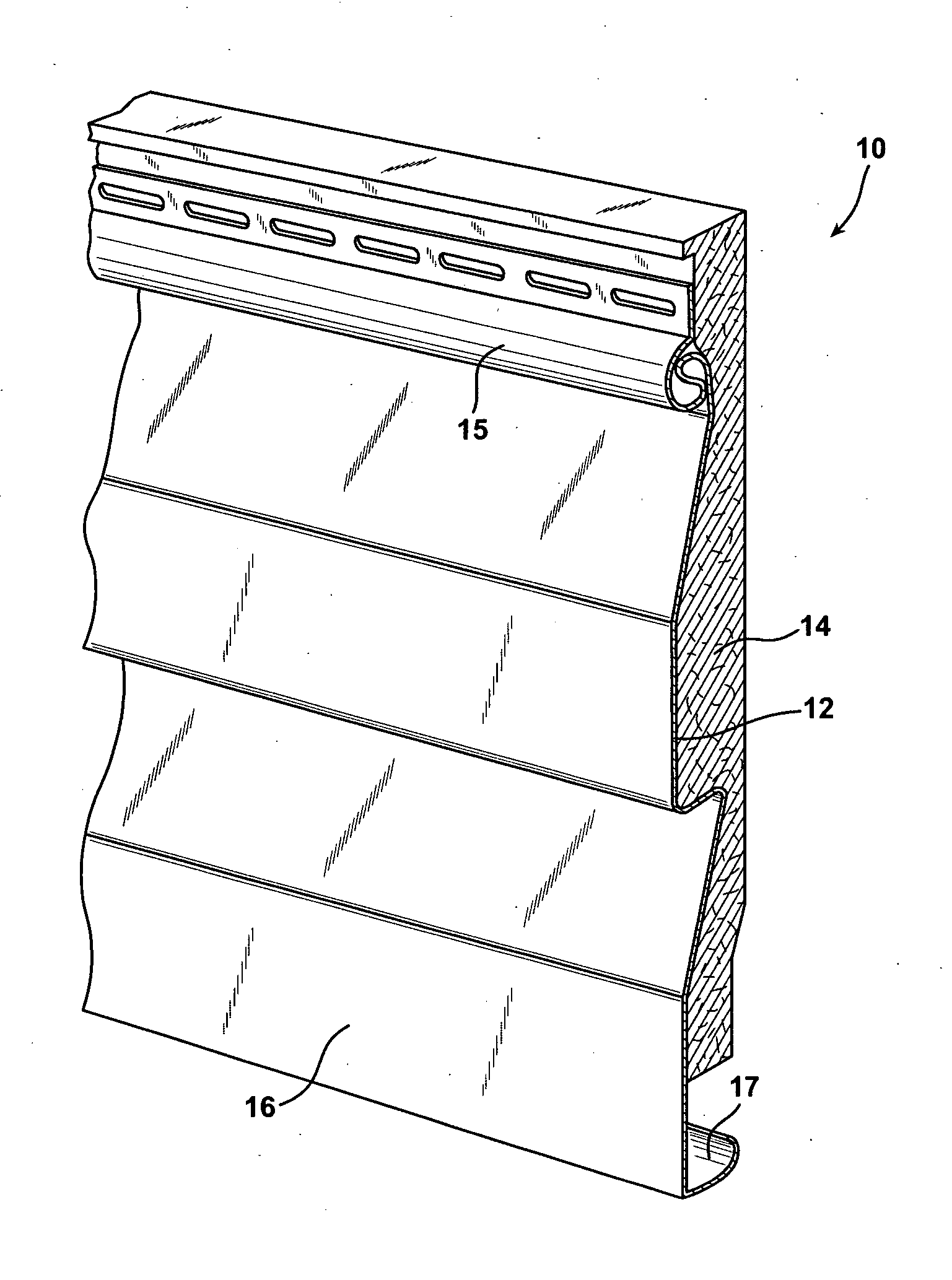

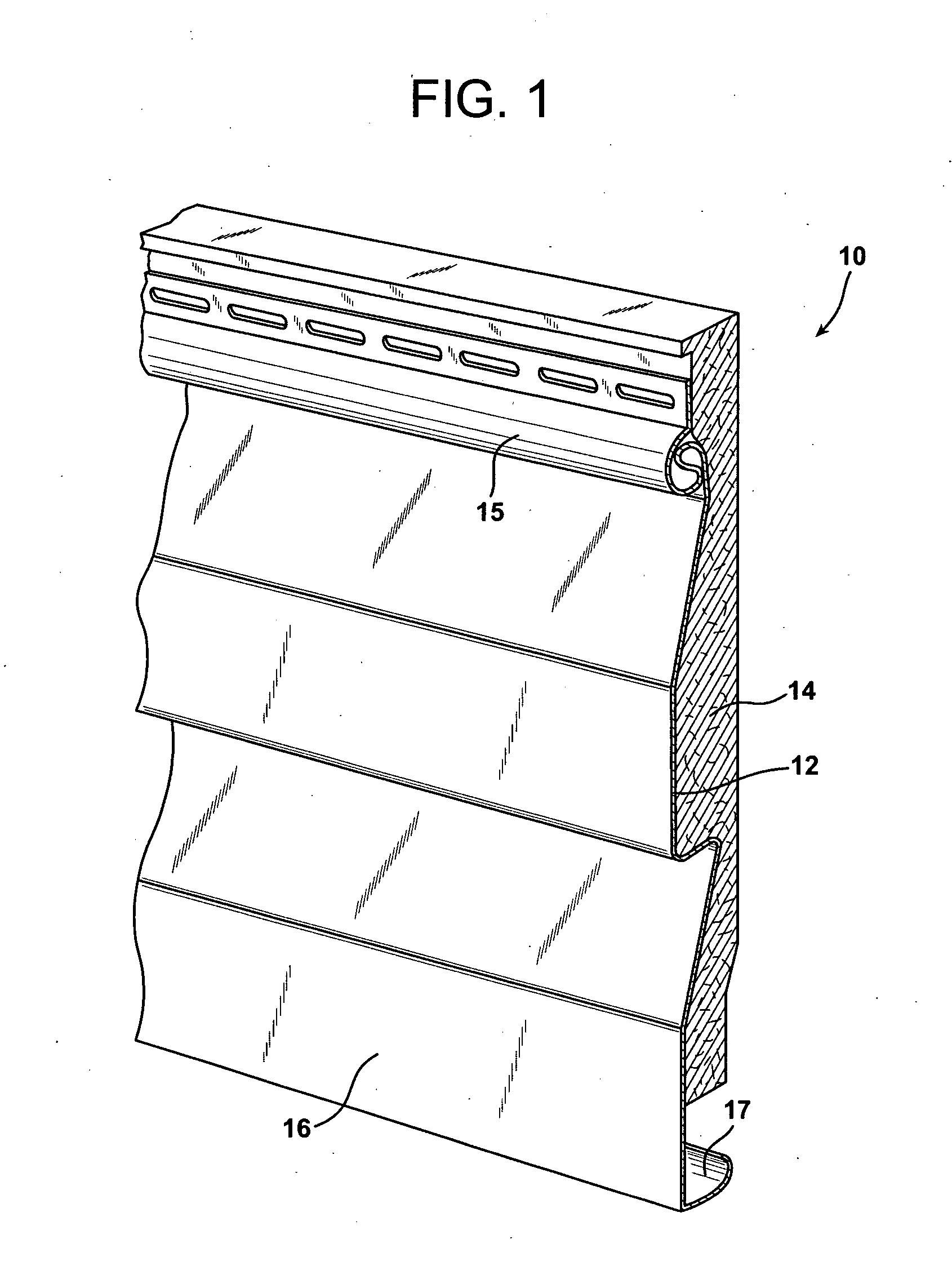

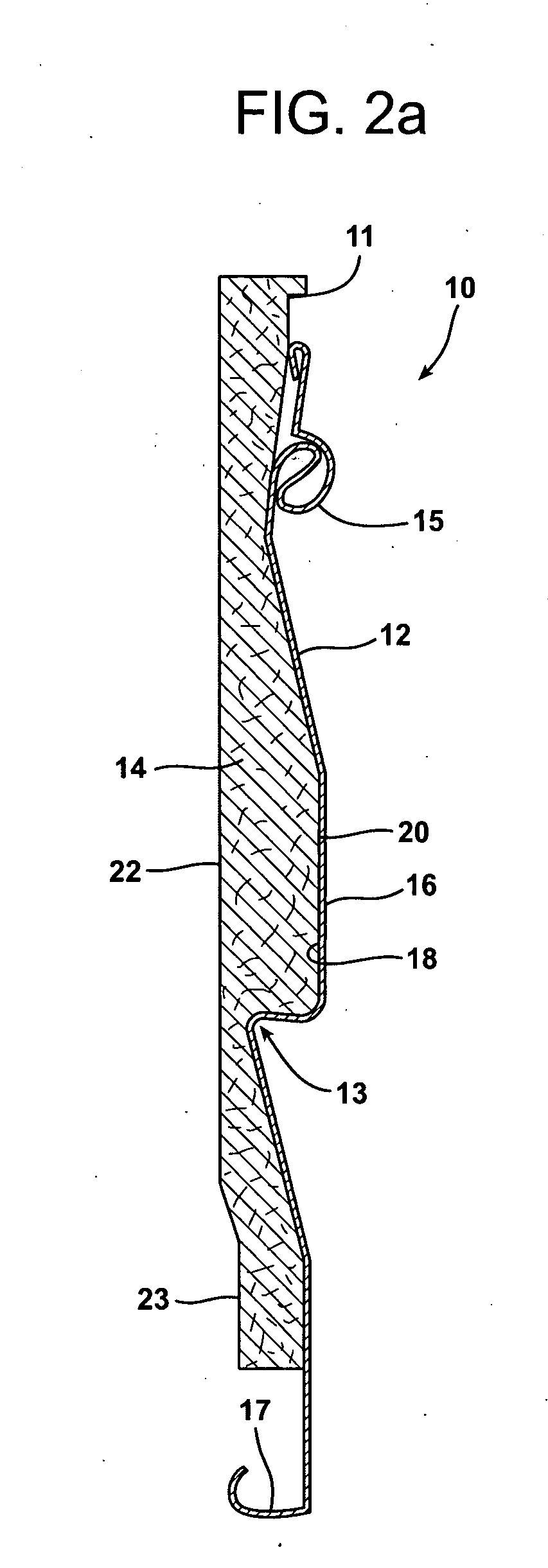

[0026] Reference is now made to FIG. 1 which illustrates the siding panel assembly 10 of the present invention. As illustrated in the FIG. 2a embodiment, the siding panel assembly 10 incorporates an ornamental facing 12 and a first insulation layer 14. The ornamental facing 12 preferably includes a tongue 15 at one end and a groove 17 at the opposite end to allow one siding panel assembly 10 to be connected to another by lapping margins in a manner well known in the art. The ornamental facing 16 may be constructed from any number of appropriate materials including but not limited to fiberglass, vinyl, polyvinyl chloride, aluminum, steel, ABS, other polymers, concrete, wood, natural fibrous materials, and mixtures thereof. The ornamental facing 12 may include an exposed, textured face 16 made, for example, to look like wood siding.

[0027] As further illustrated in FIG. 2a, the ornamental facing 12 includes a concavity formed by the contoured rear face 18. This shaping of the ornament...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com