Break-apart assembly for supporting an exhaust flue

a technology of exhaust flue and assembly, which is applied in the direction of chimneys, combustion processes, lighting and heating apparatus, etc., can solve the problems of insufficient technology and parts, and the cost of using separate parts, and achieve the effects of low cost, easy breaking, and small spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

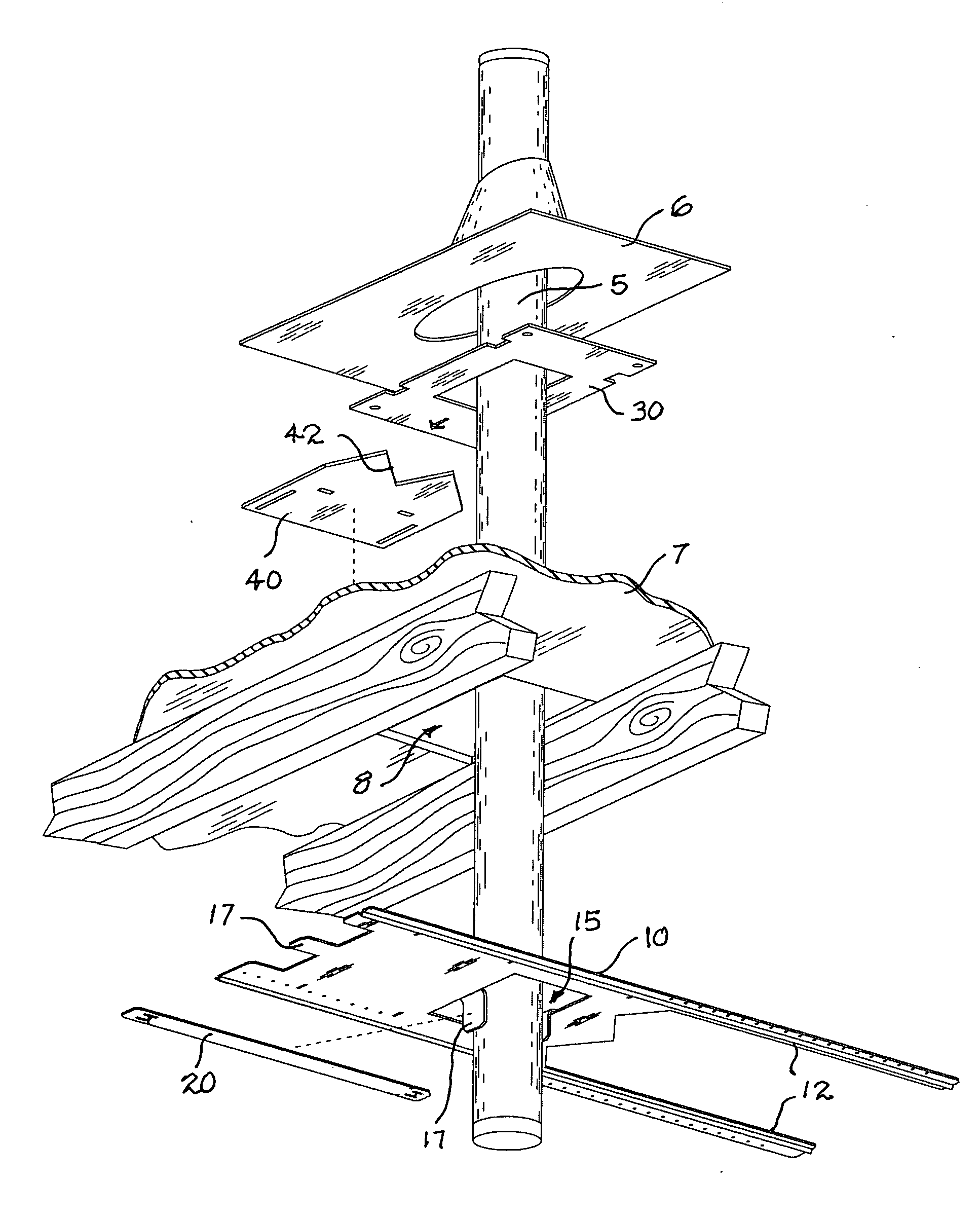

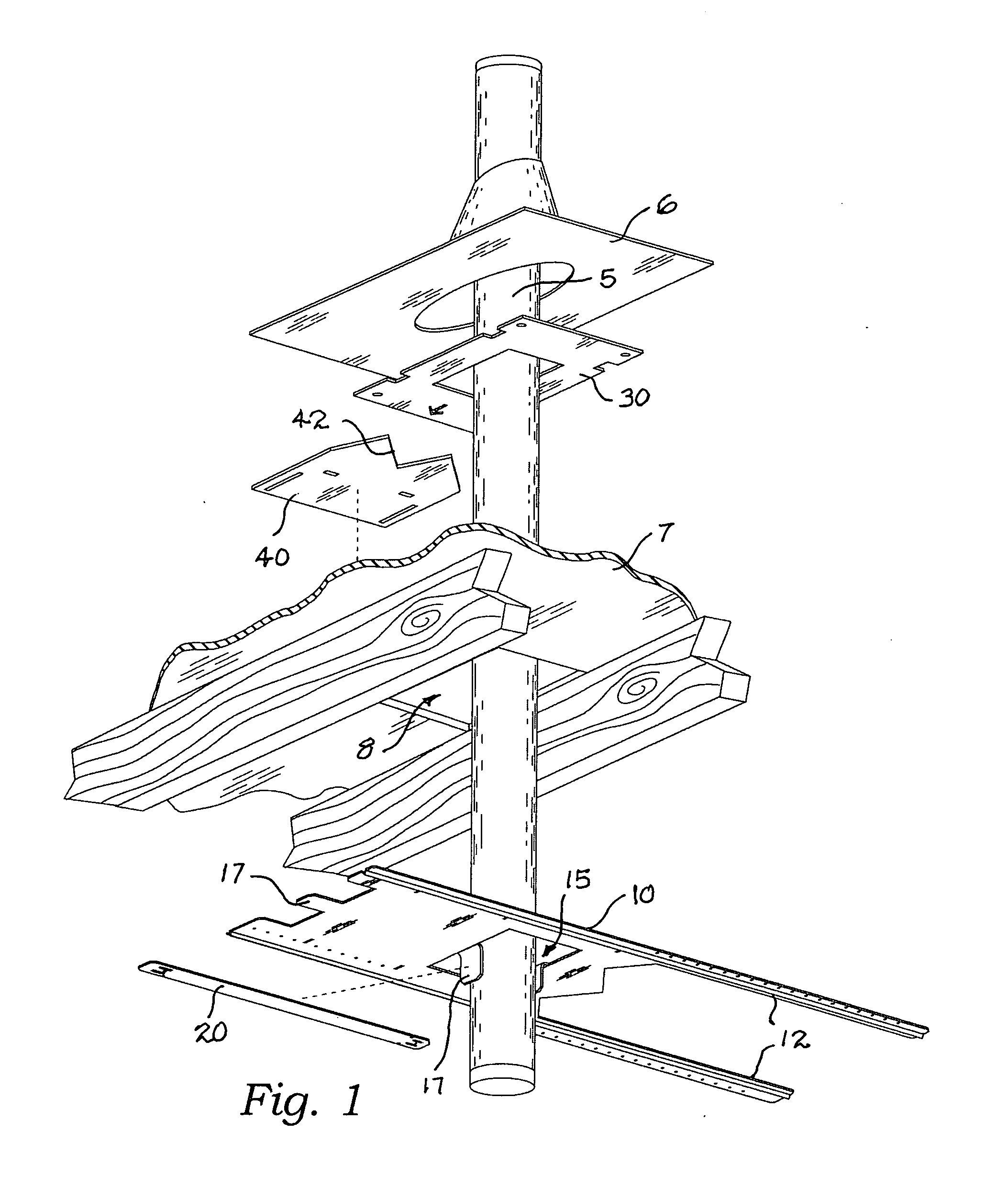

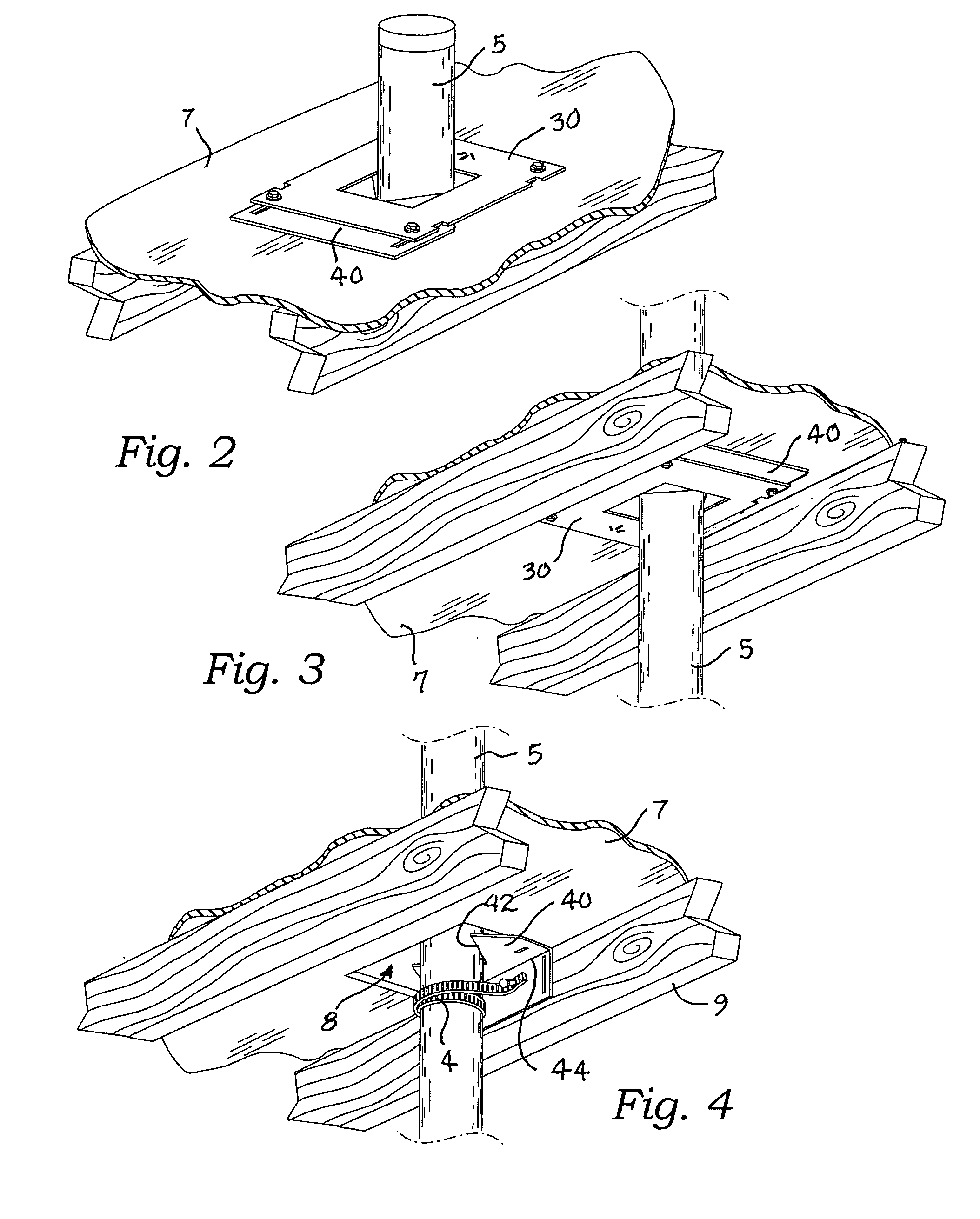

[0026] Described now in detail is an exhaust flue support apparatus, the subject of this application. This apparatus comprises an elongate flue mounting plate 10 defining a longitudinal direction, see arrow “A.” The mounting plate 10 incorporates at least two longitudinal, spaced-apart, strengthening beads 12 (FIGS. 7 and 8) which may be V-shaped or semicircular in cross-section. Other shapes are possible as well. The purpose of these beads 12 is to prevent lateral bending of the mounting plate 10, which is necessary for it to perform its function. The mounting plate 10 is engaged by break-off tabs 14 with a securing strap 20, a centering plate 30, and a butting plate 40 and these four parts: 10, 20, 30 and 40 are arranged in planar juxtaposition as shown in FIGS. 5 and 6. These four parts 10, 20, 30 and 40 are preferably made from a single flat piece of 24 gauge galvanized steel sheet metal and are preferably fabricated at the same time through punching and bending operations well ...

second embodiment

[0027] The mounting plate 10 provides plural mounting holes 16 which are preferably arranged in longitudinal rows as shown, and preferably the rows are placed adjacent to and in line with the opposing lateral edges 18 of the mounting plate 10. The mounting plate 10 also provides a first flue access hole 15 with one or more contiguous strapping-tabs 17 extending into the area defined by the flue access hole 15. Preferably, in one embodiment shown in FIG. 5, the strapping-tabs are aligned longitudinally. In a second embodiment, shown in FIG. 6, the strapping-tabs 17 are oriented at an acute angle to the longitudinal direction. In this embodiment, the tabs 17 are preferably set in pairs and form a V-shape as shown in FIG. 6. Preferably, as shown in FIG. 5, the mounting plate 10 provides a pair of laterally spaced-apart second flue access holes 15′ which are open to an end edge 18′ of the mounting plate 10. In the forming of these holes 15′, preferably by a punching operation, a strappi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com