Leg brace for stilts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

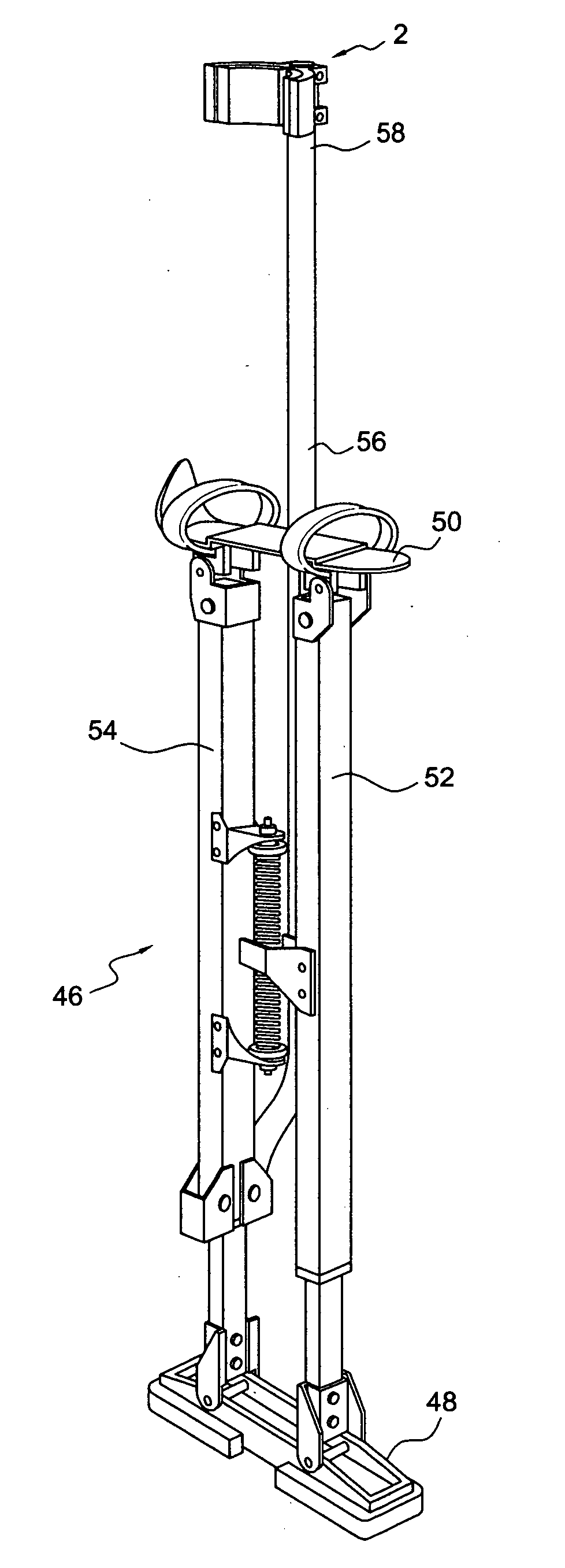

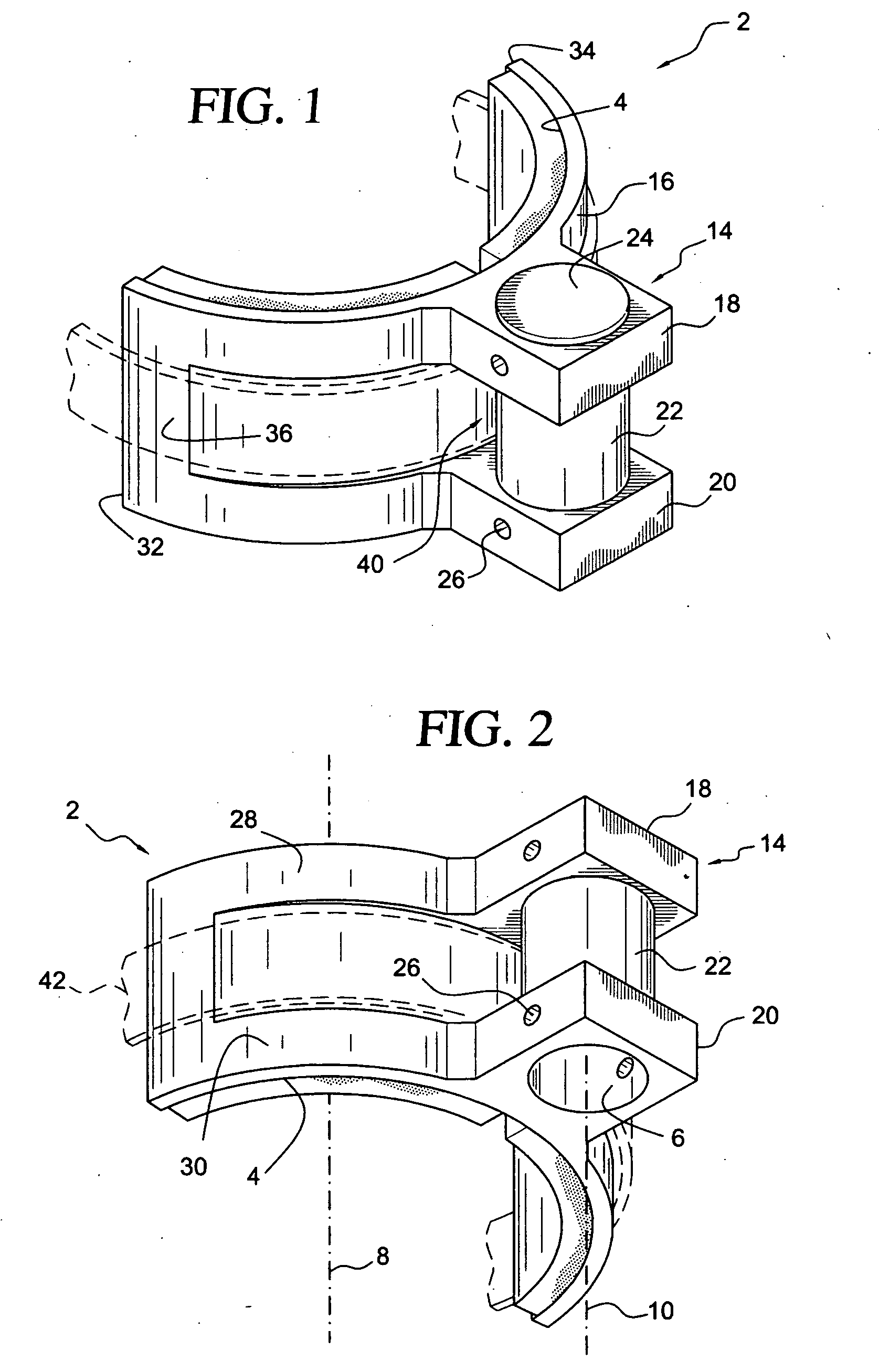

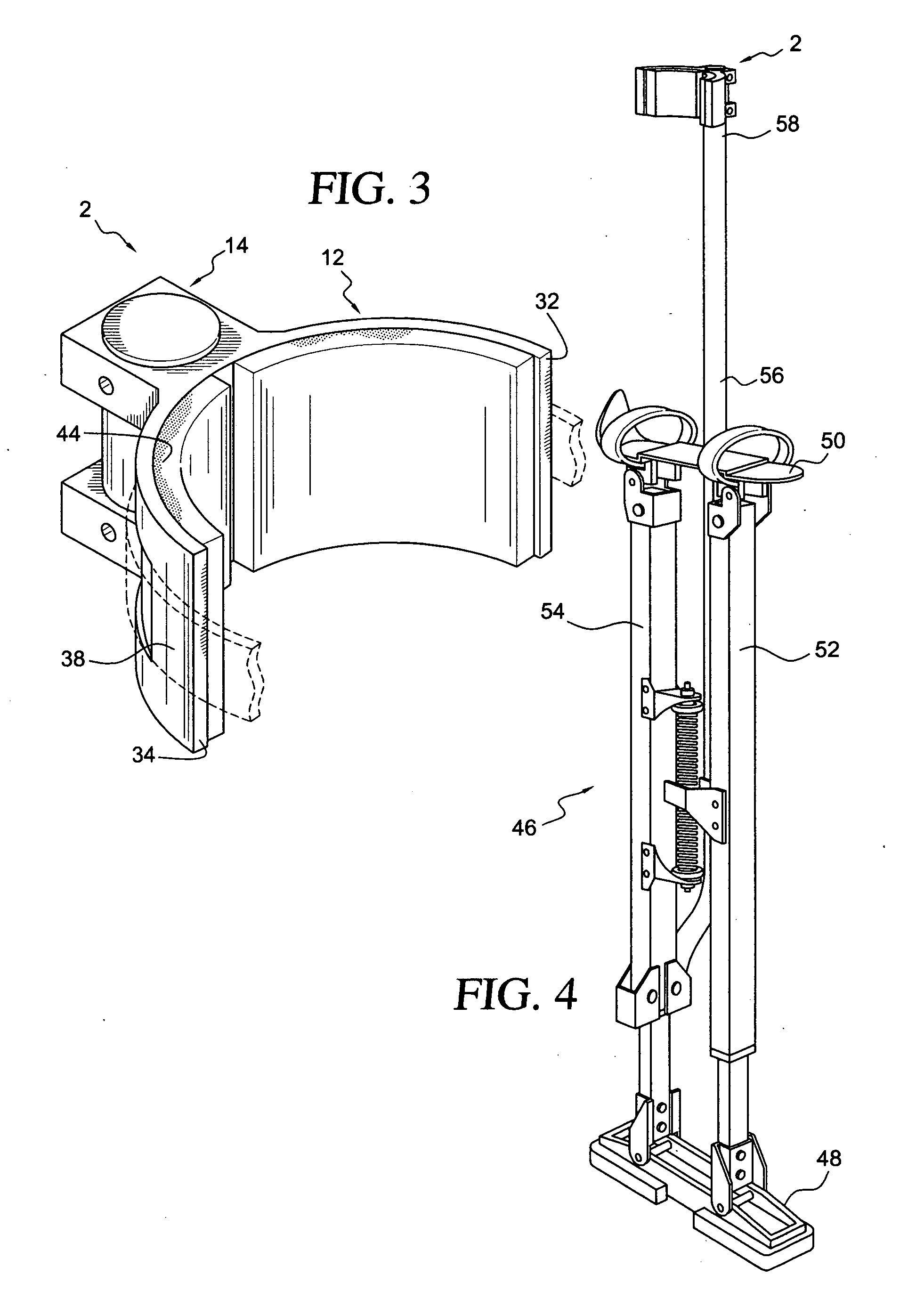

[0014] With reference to FIGS. 1 and 2, there is shown a non-metallic unitary leg brace element 2 for a stilt. The leg brace element comprises a plastic body. The plastic body defines a generally semi-cylindrical concave inside surface 4 for supporting a stilt user's leg, and a passage 6 spaced apart from the generally semi-cylindrical concave inside surface for receiving a leg support of the stilt.

[0015] A wide range of plastic material is suitable for construction of the brace element 2. For cost and speed of production, a thermoplastic would be preferred. For strength, a fiber reinforced thermoplastic would be preferred. For durability, an engineering thermoplastic would be preferred. Short glass fiber reinforced polyetheretherketone (PEEK) is a suitable material, for example. The brace element 2 is preferably produced by an injection molding process.

[0016] The generally semi-cylindrical concave inside surface is positioned around a longitudinal axis 8. A longitudinal axis 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com