Aquapac

a technology for aquariums and flowers, applied in the field of aquariums, can solve the problems of affecting the affecting the appearance of aquariums, and prone to leakage of systems, so as to reduce the requirements of landfill disposal, the effect of economic and efficient process and enhanced stability of floral foam blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

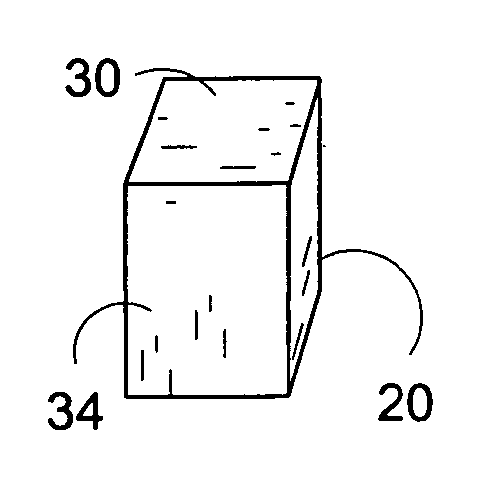

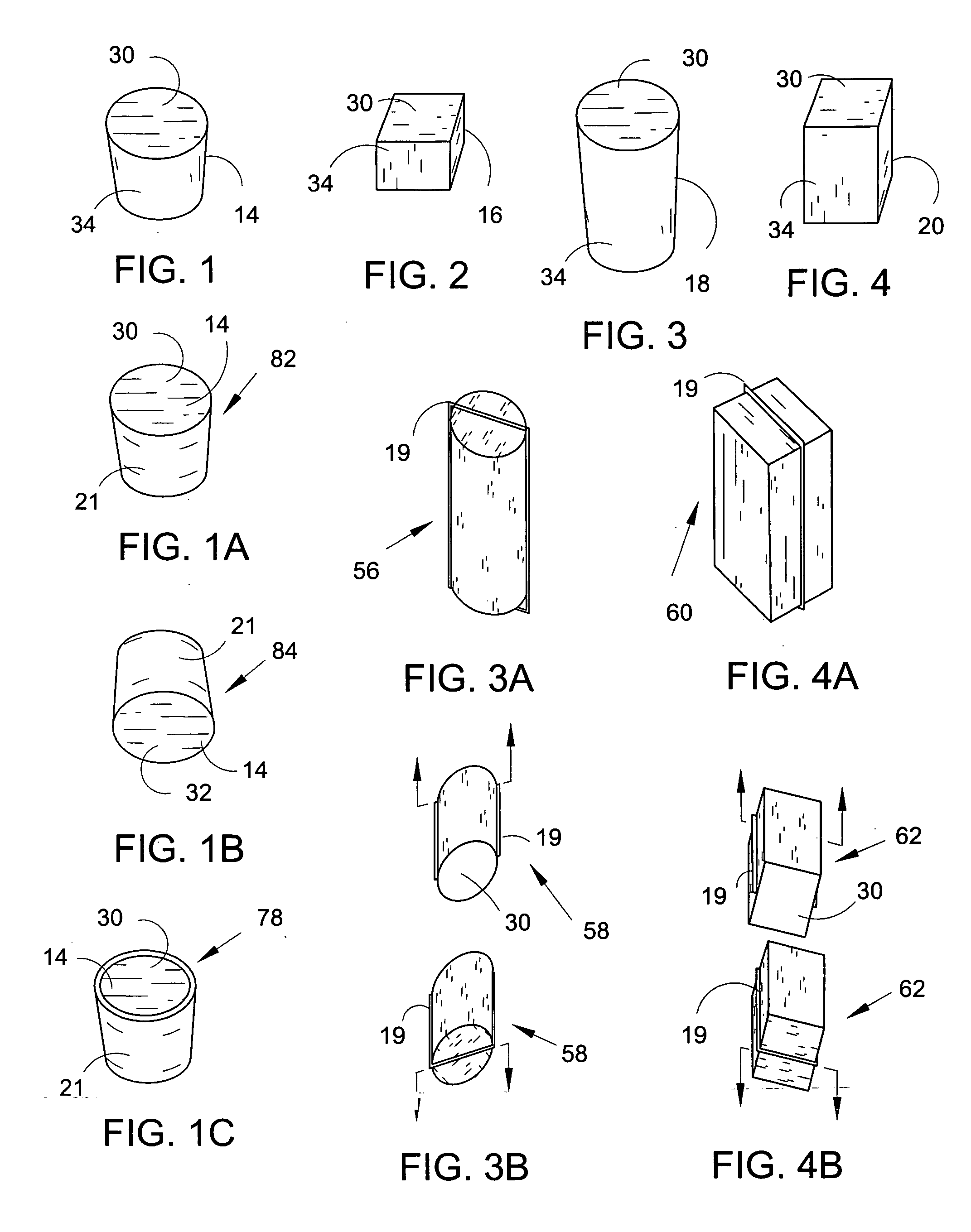

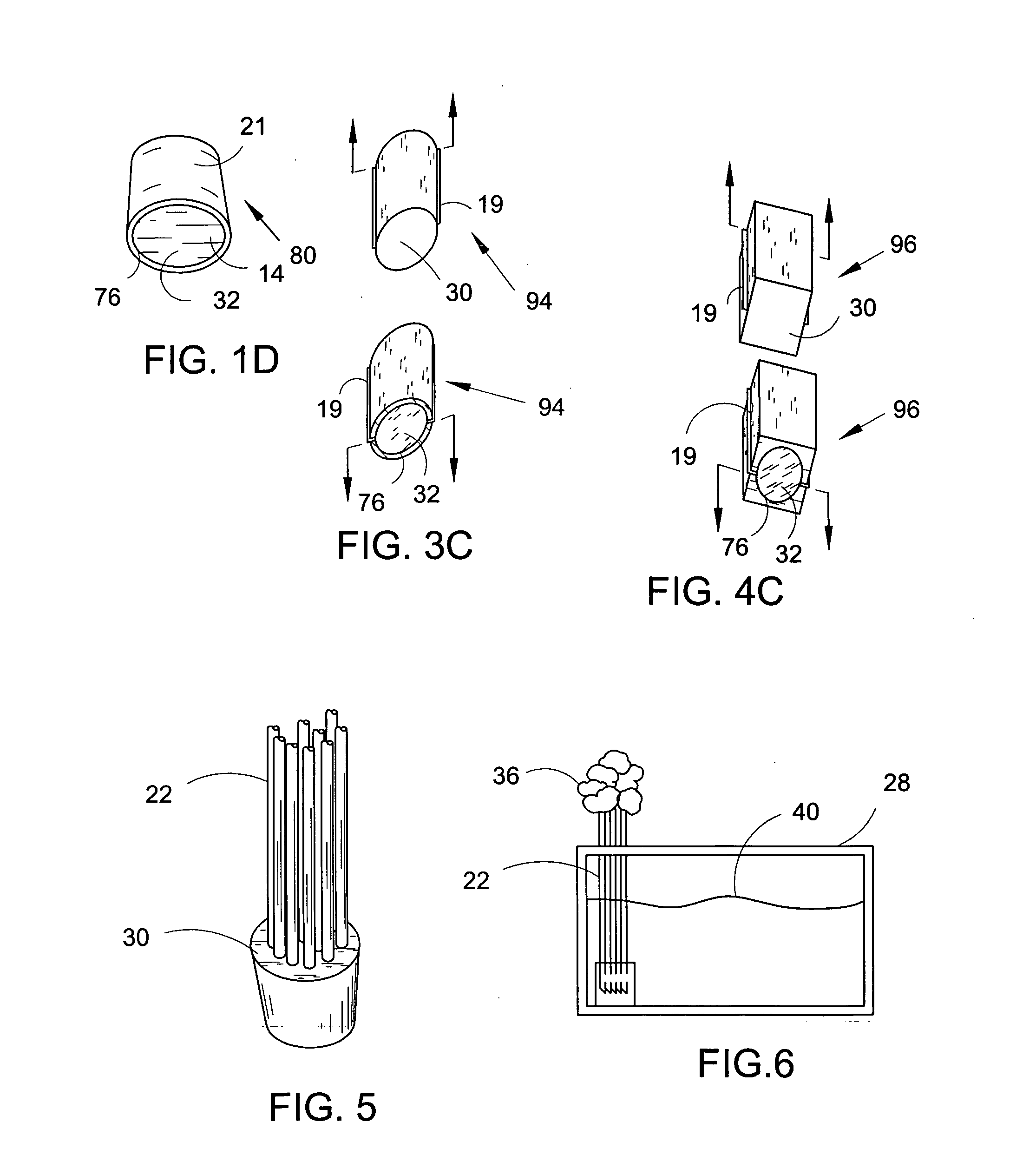

[0105] The second preferred embodiment is shown in FIGS. 1A-1D, 3-3C and 4-4C and is processed in the same manner as the first embodiment above except it provides another step in evaporation prevention. FIGS. 3 and 4 show floral foam blocks 18 and 20 in cylindrical and rectangular forms respectively that are twice as long as required. Floral foam blocks 18 and 20 are then shrink-wrapped using conventional total enclosure shrink-wrap materials 19 and processes; or are shrink-wrapped utilizing the conventional sleeve type of shrink-wrapping materials 21 and processes.

[0106] The conventional shrink-wrapping process creates shrink-wrapped twice-length cylindrical floral foam block 56 and shrink-wrapped twice-length rectangular floral foam block 60 respectively as shown in FIGS. 3A and 4A. These shrink-wrapped floral foam block assemblies 56 and 60 are then severed into two approximately equal length cylindrical segments 58 and cubical segments 62 respectively as shown in FIGS. 3B and 4B...

fourth embodiment

[0113] The fourth embodiment entails adding stem wells 52 into the floral foam blocks to minimize crushing of the foam material from flower stem insertion as illustrated in FIGS. 8F, 9C, 10A-10C and 11A and 11B.

[0114] Addition of stem wells 52 in floral foam blocks 15 and 17 is shown in FIGS. 10A and 11A respectively. Stem wells 52 provide clearance for stems 22, maximizing the moisture absorption capability of these foam blocks by reducing the crushing of the floral foam from forcing flower stems 22 into solid floral foam blocks. This modification entails forming stem wells 52 in a pattern to fit the size and number of stems 22 in the intended bundle 36 to be shipped. Stem wells 52 are preferably formed starting at top surface 30 and progressing to a depth of approximately one half of perimeter wall 34 length. Stem wells 52 preferably have an appropriate diameter such that the stem 22 walls remain in contact with the moisture bearing floral foam. The pattern of stem wells 52 needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com