Constant frequency power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

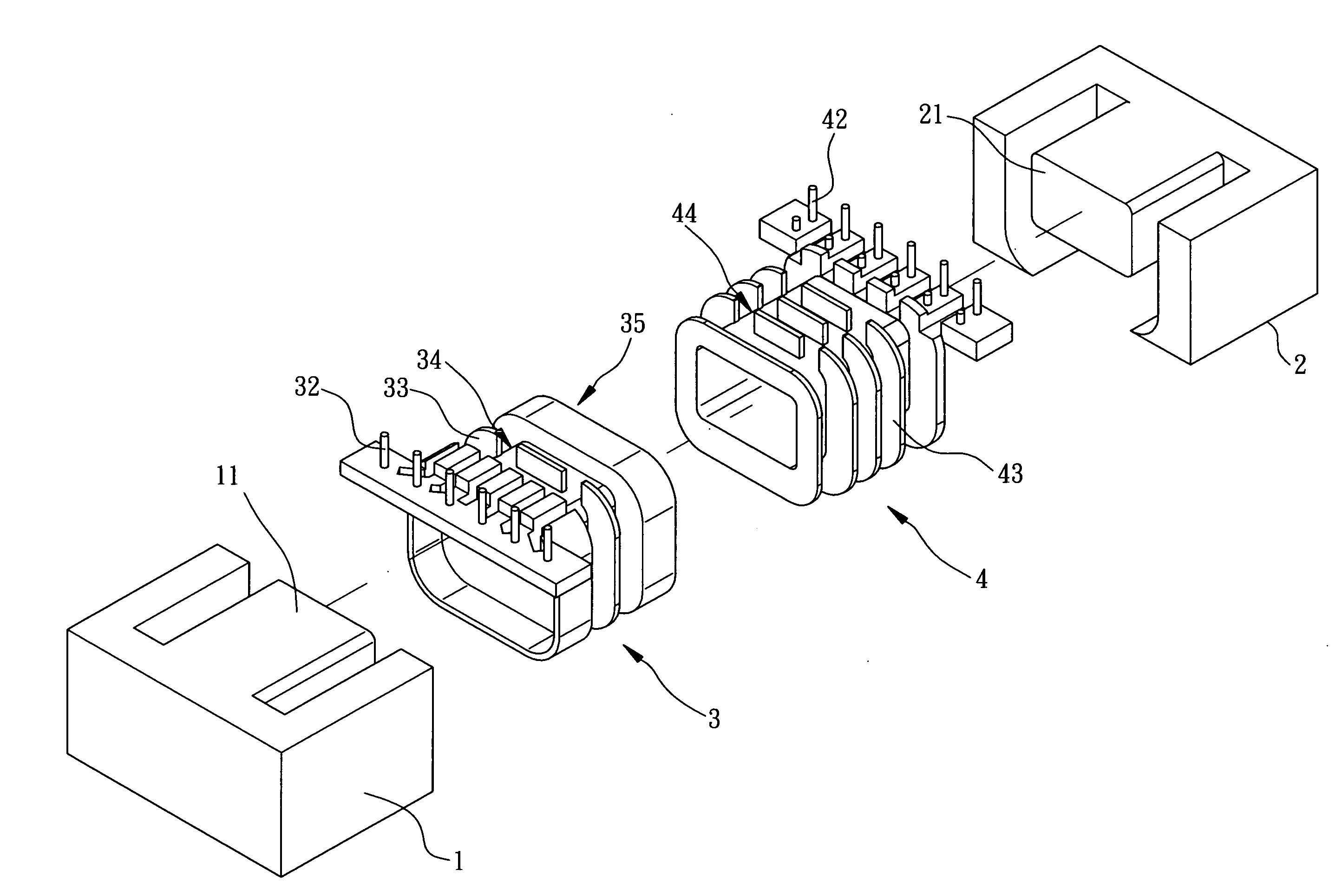

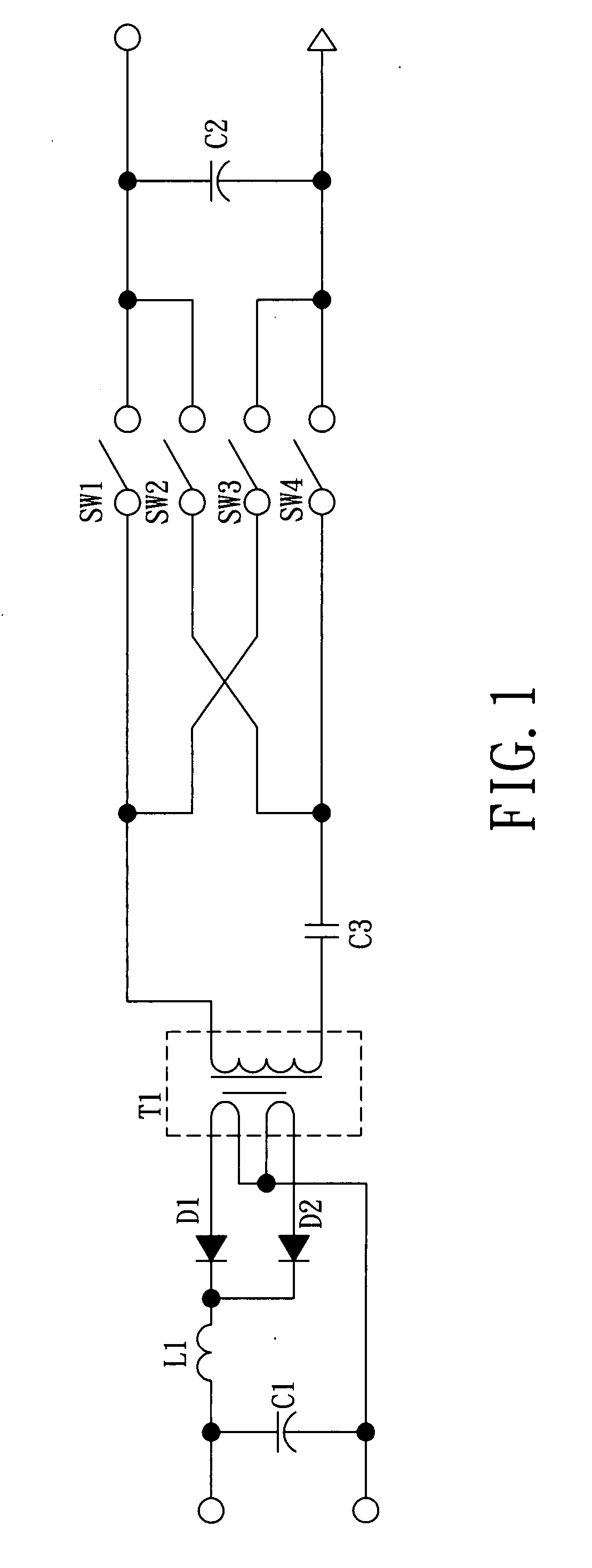

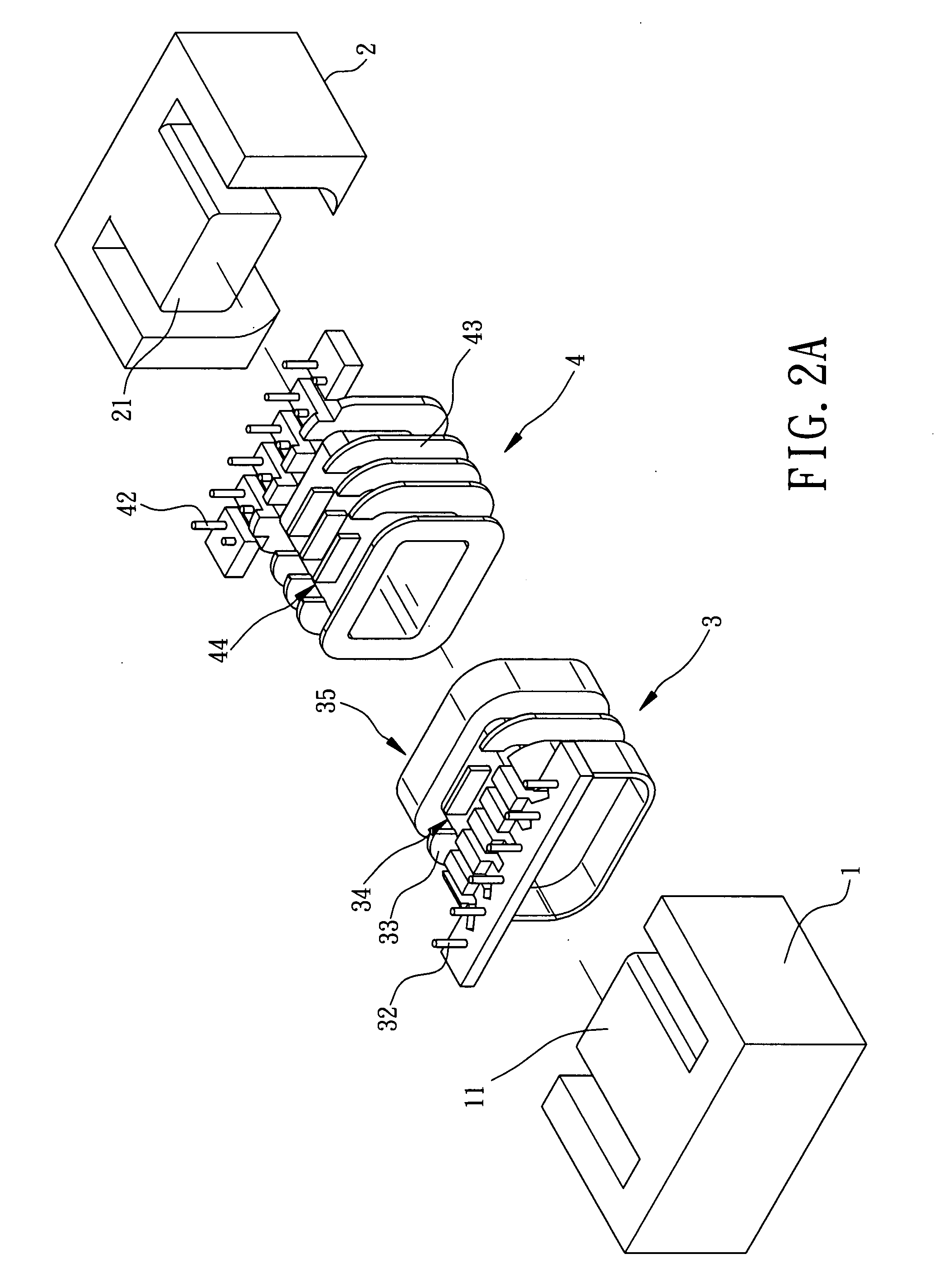

[0016]FIG. 2A is a schematic exploded view of the constant frequency power supply of the invention; and FIG. 2B is a schematic cross-sectional view of the structural combination the constant frequency power supply of the invention; while FIG. 3 is a schematic circuit diagram of the constant frequency power supply applied in whole bridge-type and exchange-type circuit of the invention. As shown in FIG. 2A, FIG. 2B, and FIG. 3, the constant frequency power supply of invention includes a first core 1, a second core 2, a first bobbin 3 and a second bobbin 4. The first core 1 and the second core 2 being disposed in opposite position are made of material with high magnetic permeability. Moreover, The first core 1 and the second core 2 have a first protruded body 11 and a second protruded body 21 respectively that are arranged in a predetermined shape. In a preferred embodiment of the invention, the first protruded body 11 and the second protruded body 21 are arranged in straight line, of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com