Mechanic's seat and step stool

a technology of seat and seat frame, applied in the field of molded work seats, can solve the problems of not being able to move the chair the use of the chair may not be convenient or adequate, and the chair is difficult to move from one place to another, and the storage typically will not include a means of storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

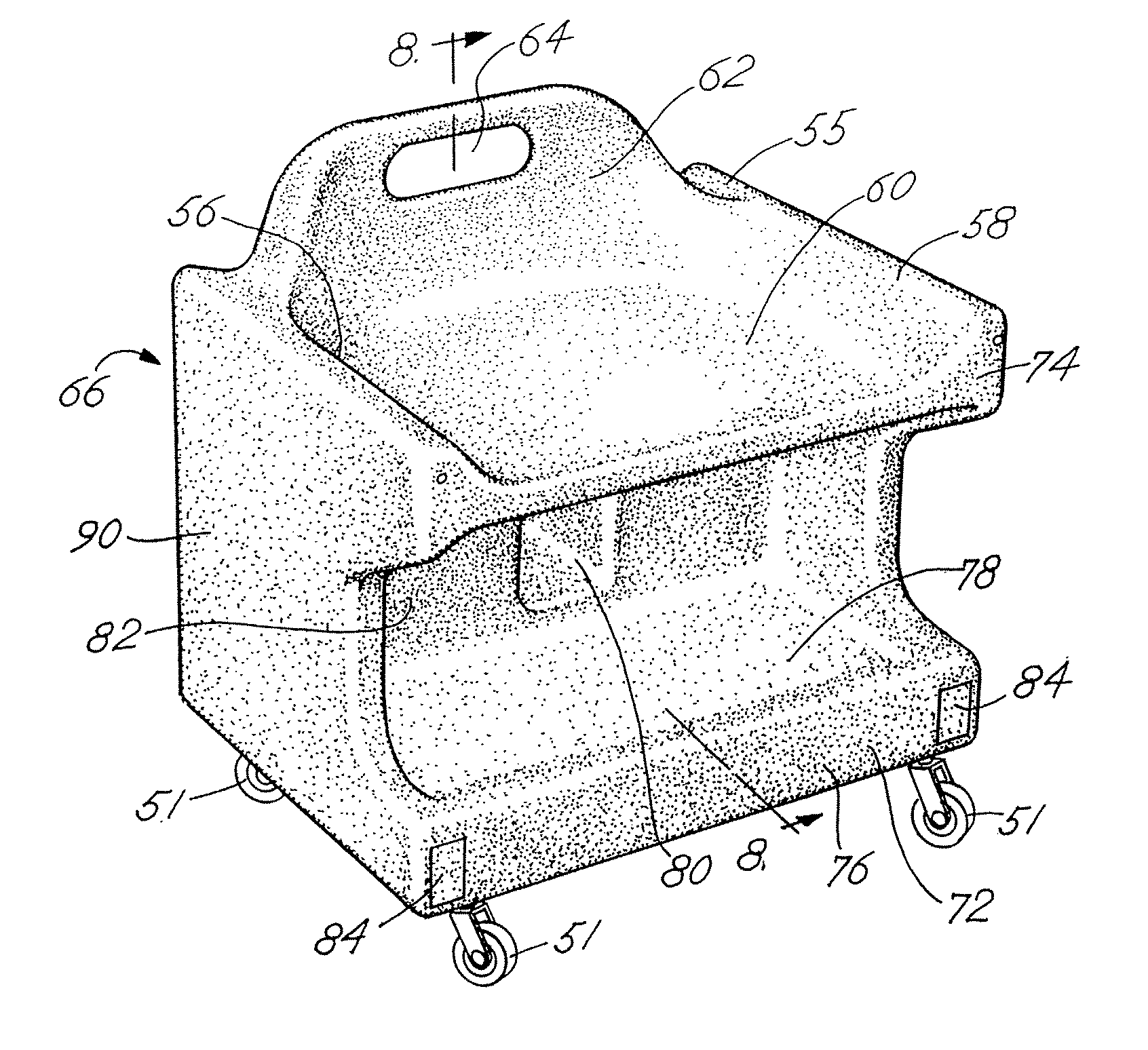

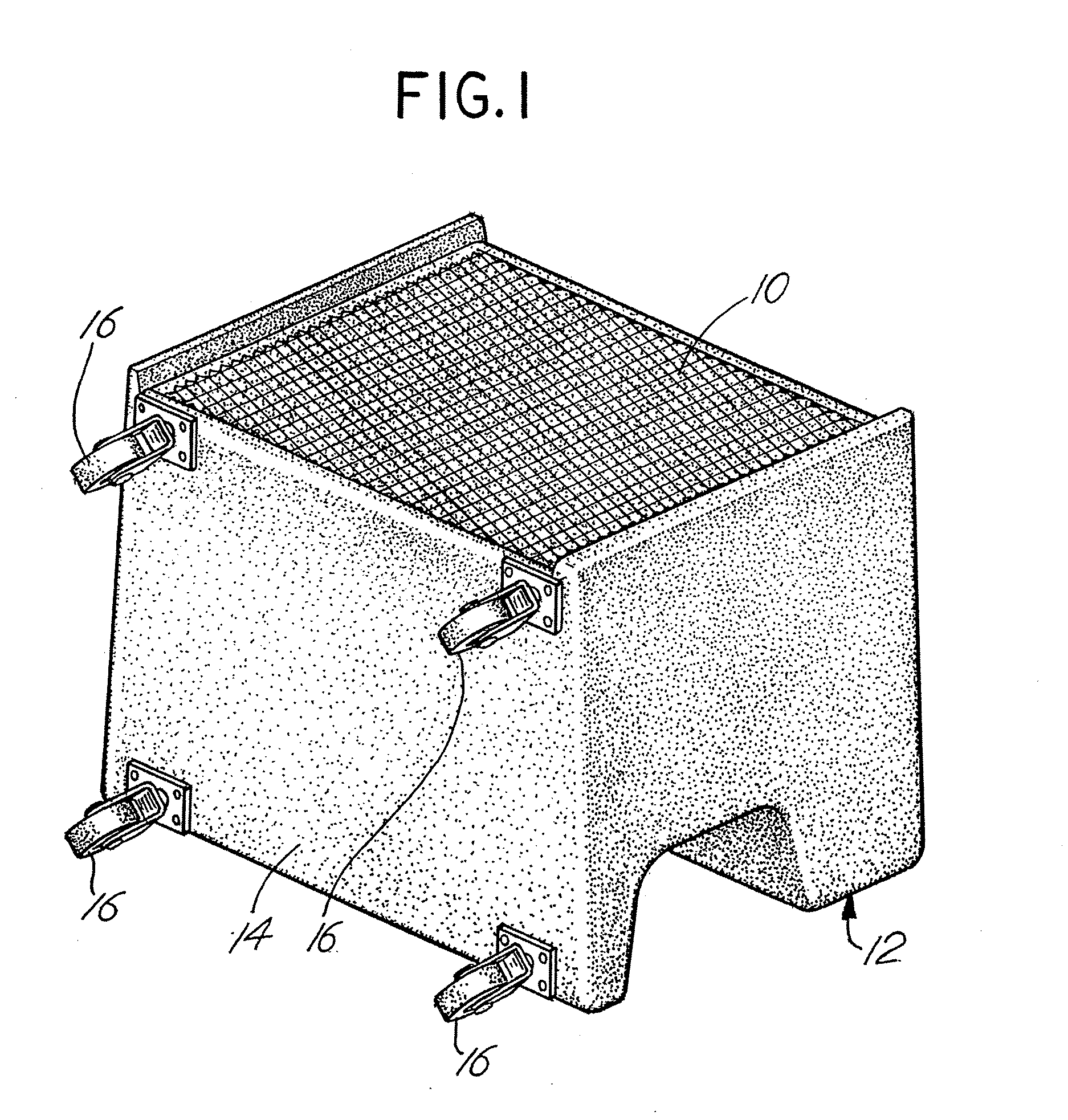

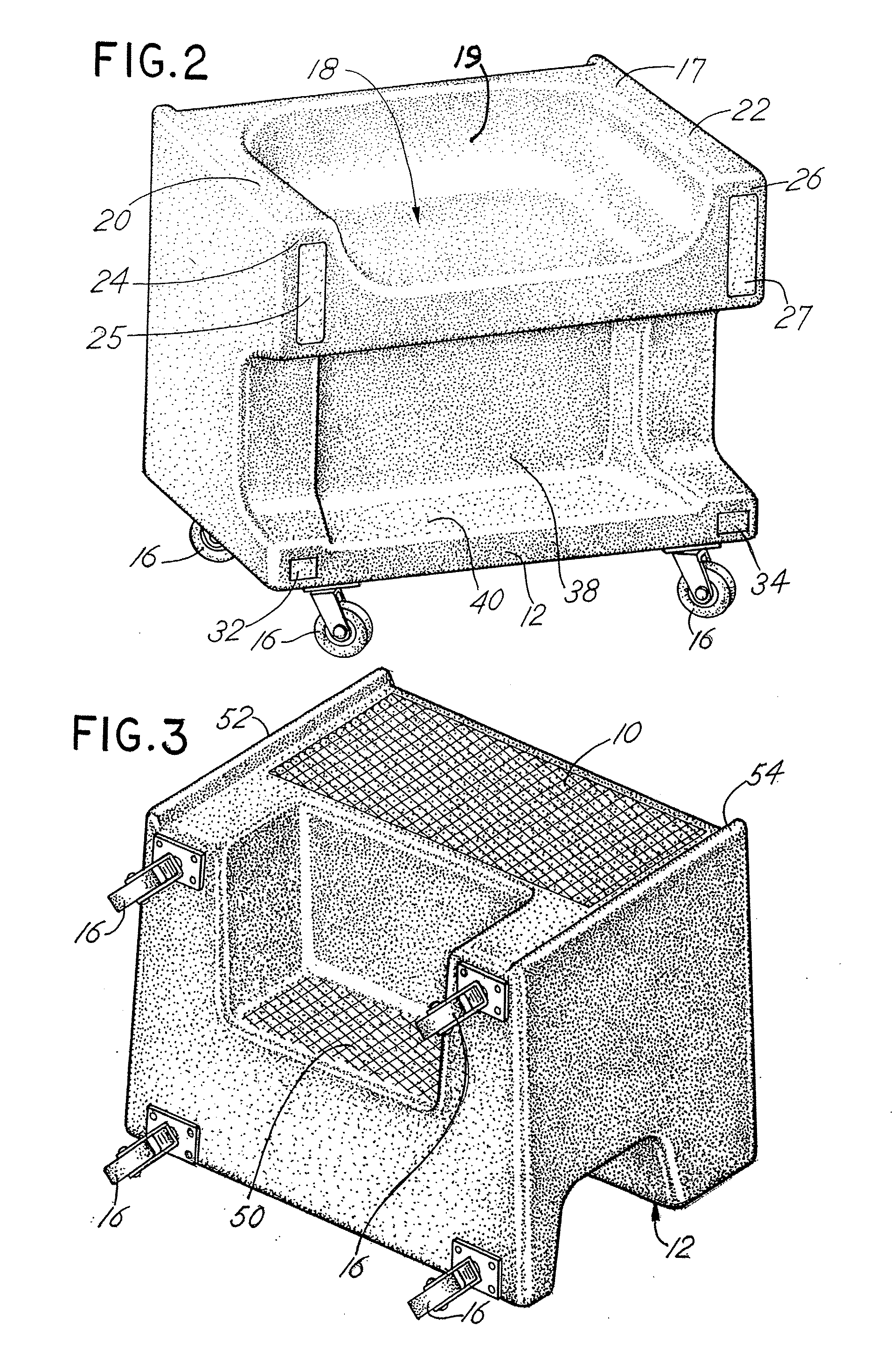

[0038]FIG. 1 illustrates a combination mechanic's seat or stool and step stool. The combination is preferably manufactured from a plastic material such as polypropylene formed by blow molding, a rotational mold process, injection molding, or other molding process. The overall general configuration is that of a parallelepiped, in particular, a rectangular parallelepiped. The molded device may have inclined sides formed with draft angles to facilitate the molding process as well as to improve the aesthetics, balance and utility of the product.

[0039] Referring to FIG. 1, the device is depicted to function as a step stool. FIG. 2 illustrates the device oriented to function as a creeper or mechanic's seat mounted on rollers or casters. When the item is utilized as a step stool, as in FIG. 1, a top face 10 includes a serrated or patterned surface to prevent slippage. A non-skid pad (not shown) may also be affixed to surface 10. Thus, top surface 10 is a generally flat, planar surface gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com