Comestible fluid rack and rail apparatus and method

a technology of fluid racks and rails, applied in the direction of cabinets, dismountable cabinets, show hangers, etc., can solve the problems of inability to change the capacity of such racks, inadequate provisions, and often inadequate needs of many users, so as to effectively match the needs of users, expand or reduce the amount of available space, and quickly disassemble and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

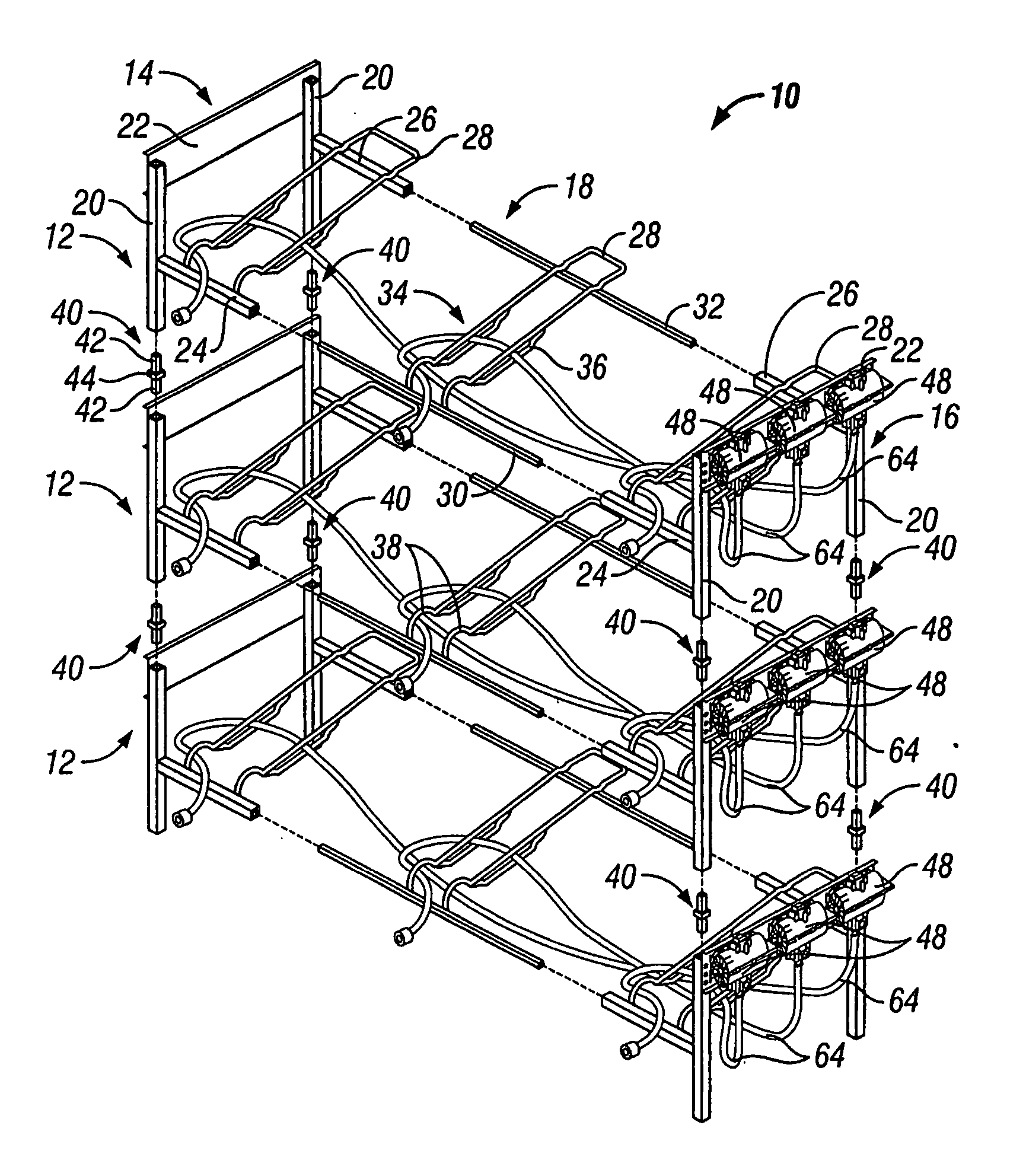

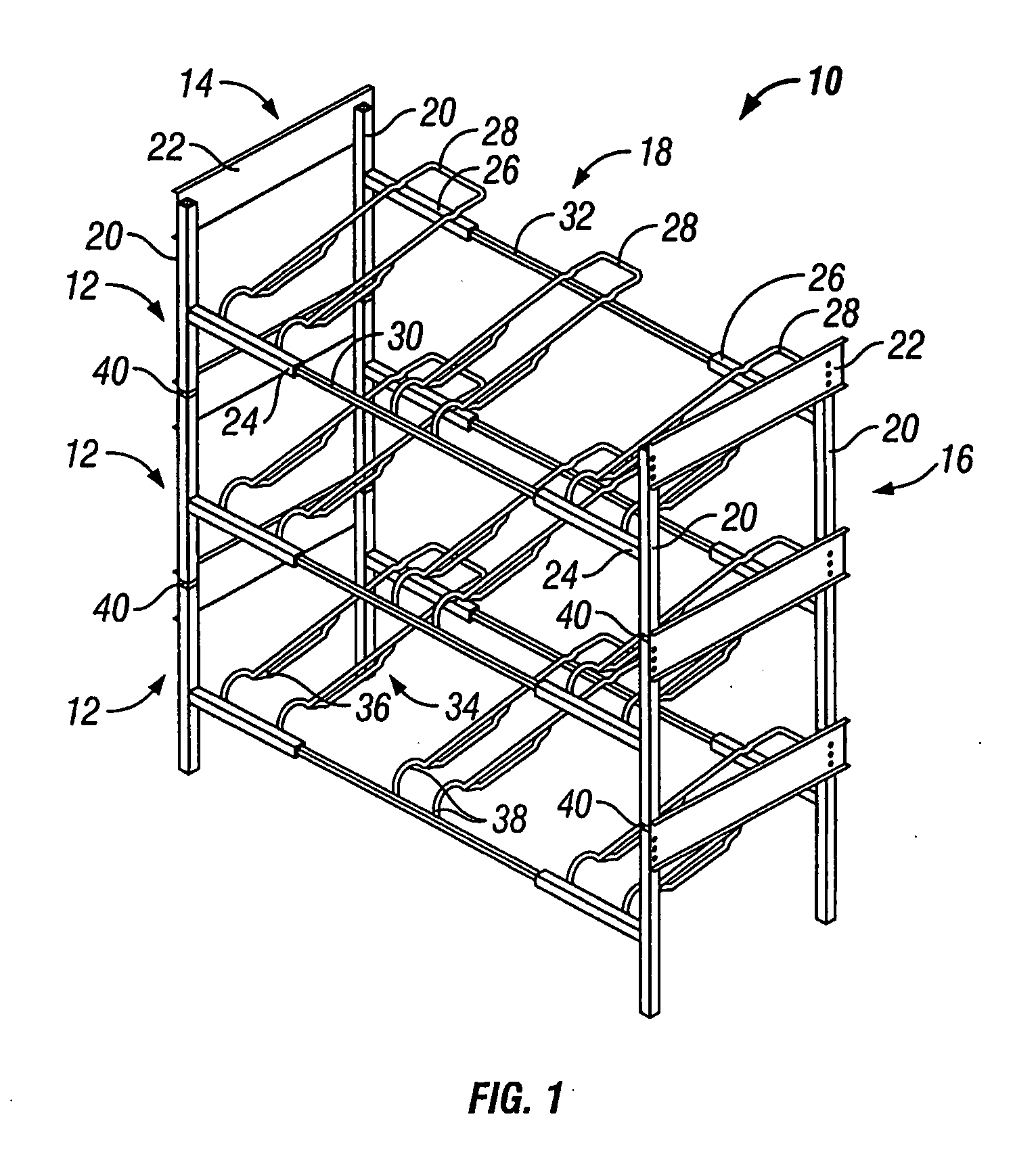

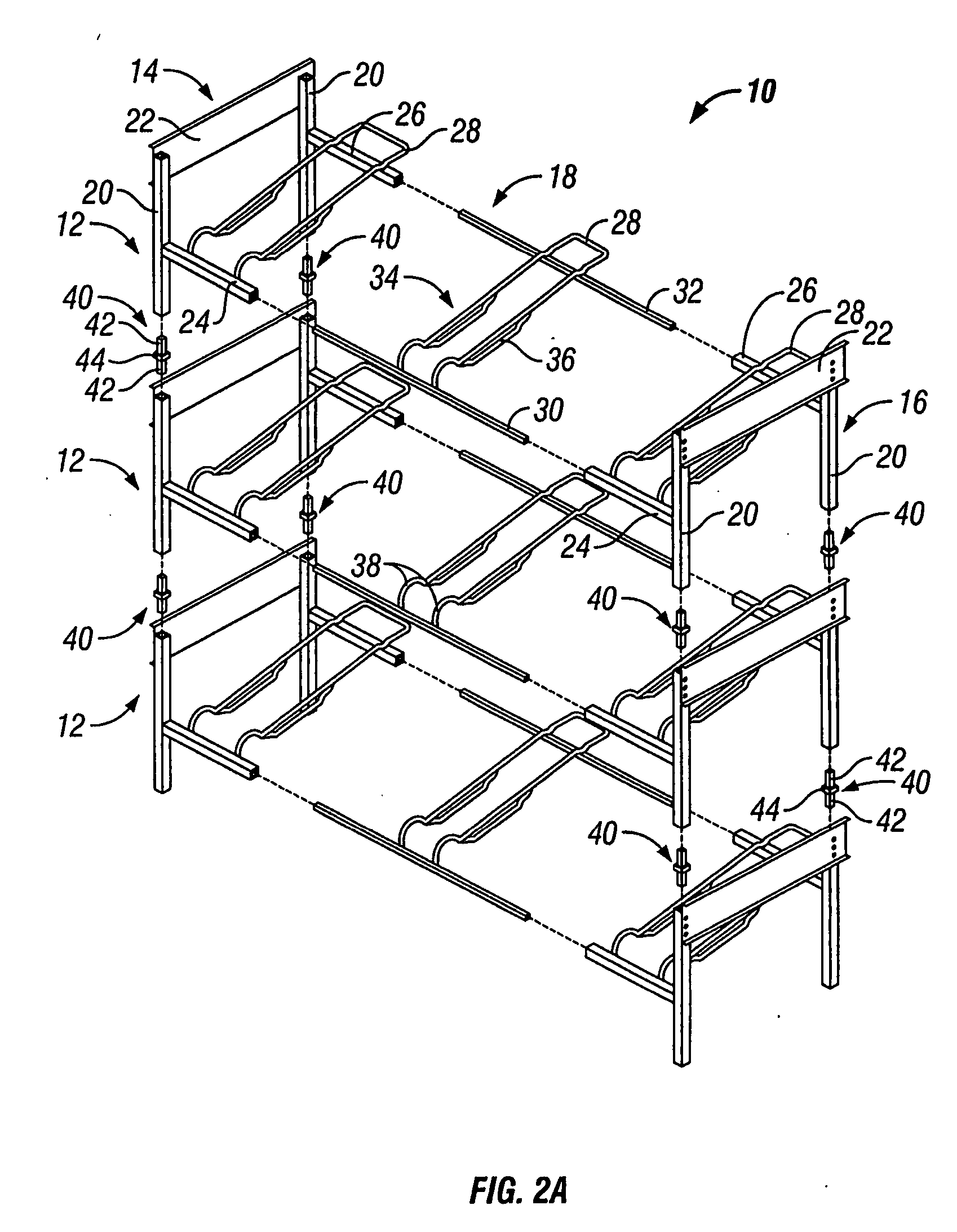

[0028] An embodiment of a comestible fluid container rack according to the present invention is illustrated in FIGS. 1 and 2A. The illustrated rack (indicated generally at 10) is adapted for holding bag-in-box type comestible fluid containers. Bag-in-box comestible fluid containers typically have a port to which a conduit 64 can be releasably connected and through which comestible fluid can be pumped, drained, or otherwise removed from the container. Although the port in such containers is typically located near the bottom of the container, the port can be in any location on the container depending at least in part upon the manner in which comestible fluid is removed from the container. Bag-in-box comestible fluid containers are well-known to those in the art and are not therefore described further herein.

[0029] Although the illustrated embodiment of the rack 10 is adapted for holding bag-in-box type comestible fluid containers, it will be appreciated that the rack 10 can be adapte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com