Vacuum sealer apparatus and a film cartridge for a vacuum sealer and a means of operating the vacuum sealer and the film cartridge

a vacuum sealer and film cartridge technology, applied in the field of vacuum sealers, can solve the problems of large current devices, clumsy and difficult to use, and the device does not provide an easy and efficient manner of sealing and storing liquid or partial liquid food items, and achieves quick and convenient packaging, quick and convenient debulking and storage of items, and quick and convenient packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Vacuum Sealer in General

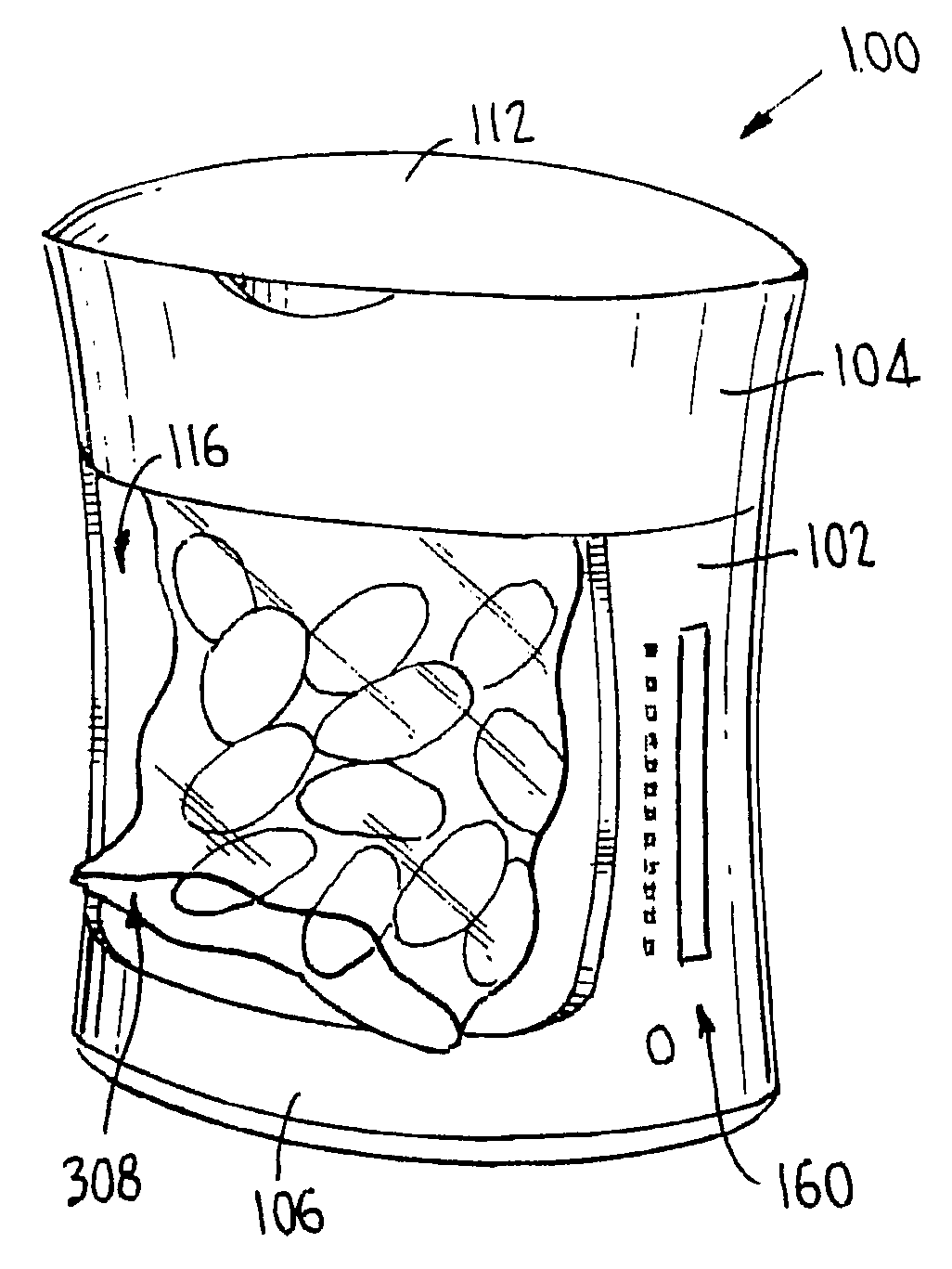

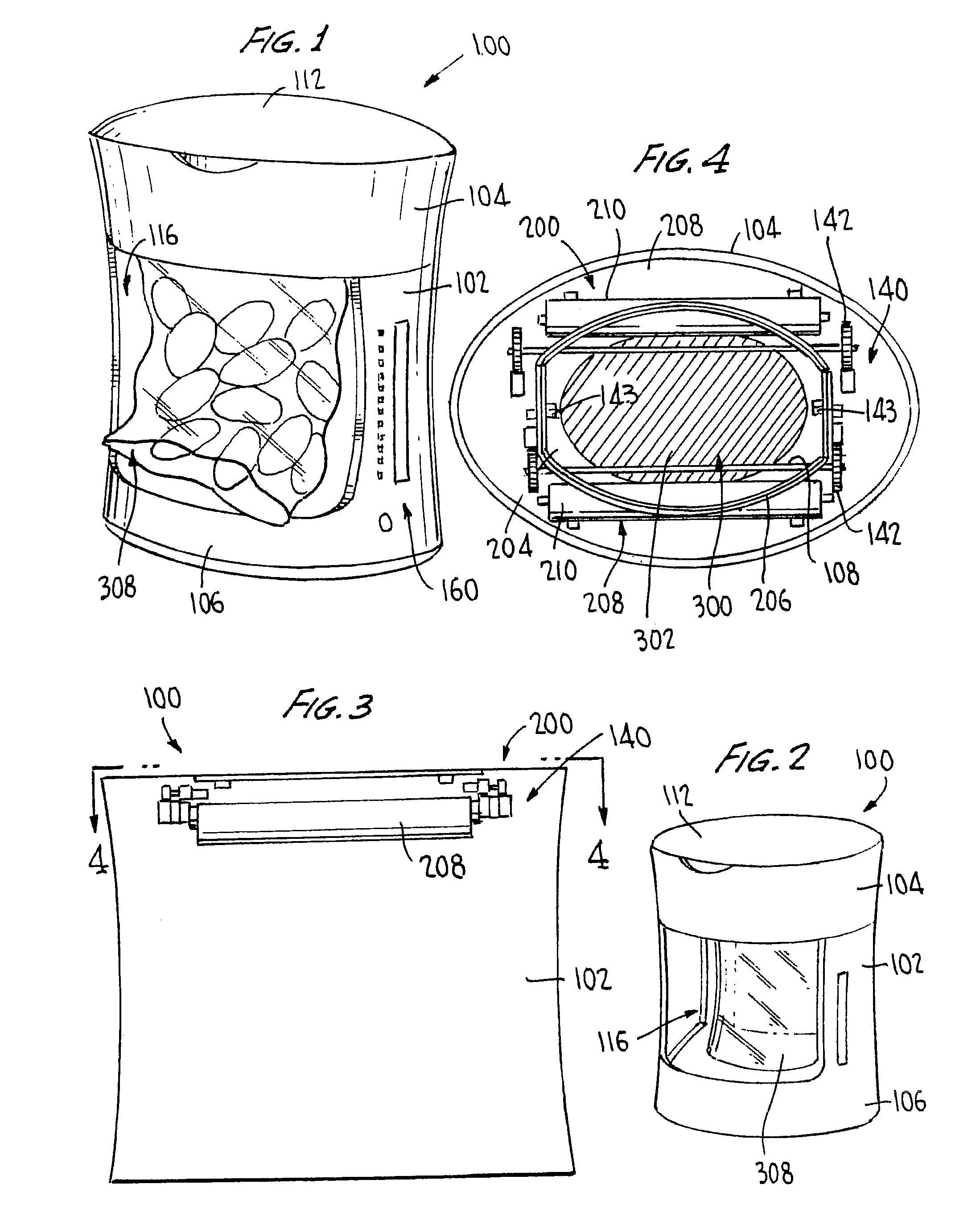

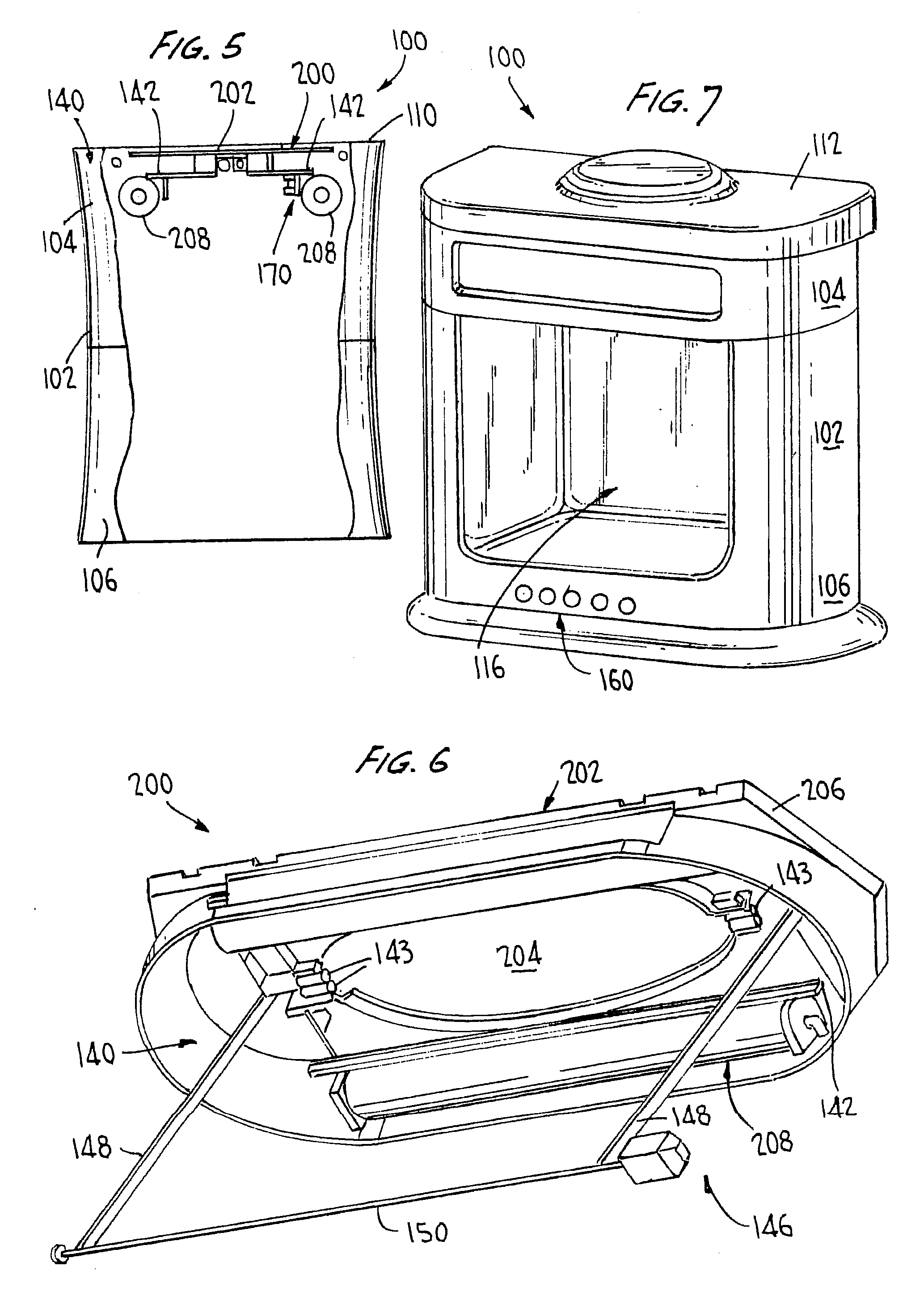

[0093] Referring to FIGS. 1-73, the present invention relates to a vacuum sealer 100 for packaging, sealing and storing items and a film cartridge 200 for a vacuum sealer 100. More particularly, the present invention is a vacuum sealer 100 having a center filling film cartridge. The invention also relates to a vacuum sealer 100 having a means to feed, form, seal and cut film bags 308 for storing items.

[0094] The vacuum sealer 100 preferably comprises a body 102, a top portion 104, a base portion 106, a film cartridge 200, a drive mechanism 140, a sealing and cutting mechanism 170 and a vacuum / pump mechanism 180. The vacuum sealer 100 preferably has a feed opening 108 through a top side of and preferably in a center of the top portion 104. The film cartridge 200 is operatively positioned in the feed opening 108 in the top portion 104. The feed opening 108 is preferably in a center of the top portion 104 of the vacuum sealer 100. The film cartridge 200 has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com