Pressure Control Valve

a technology of pressure control valve and control valve, which is applied in the direction of functional valve types, lighting and heating apparatus, refrigeration components, etc., can solve the problems of controlling valve size increase, control pressure greatly deviating, cop dropping, etc., to prevent abnormal high pressure, reduce cop, and reduce the effect of cop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

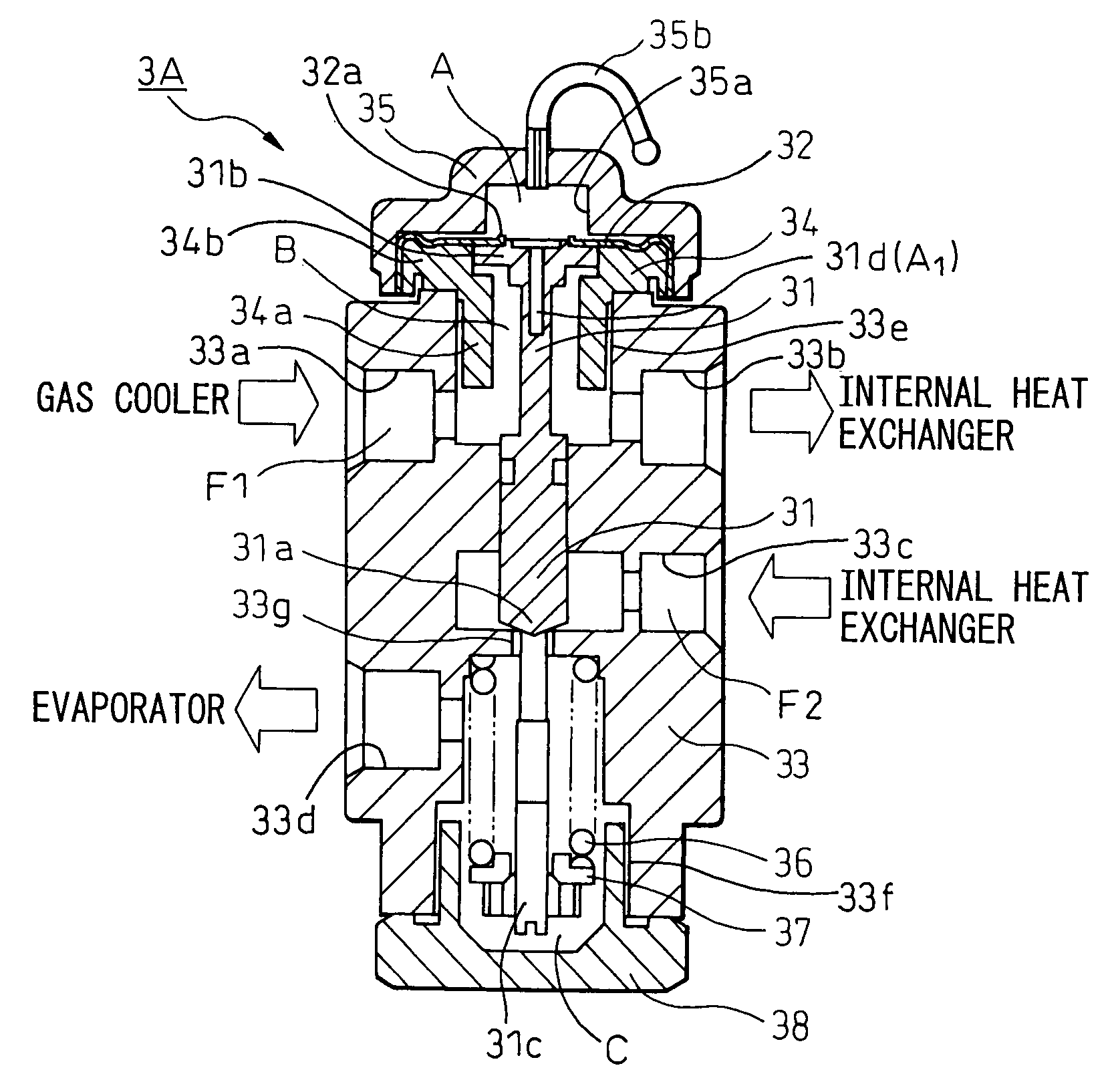

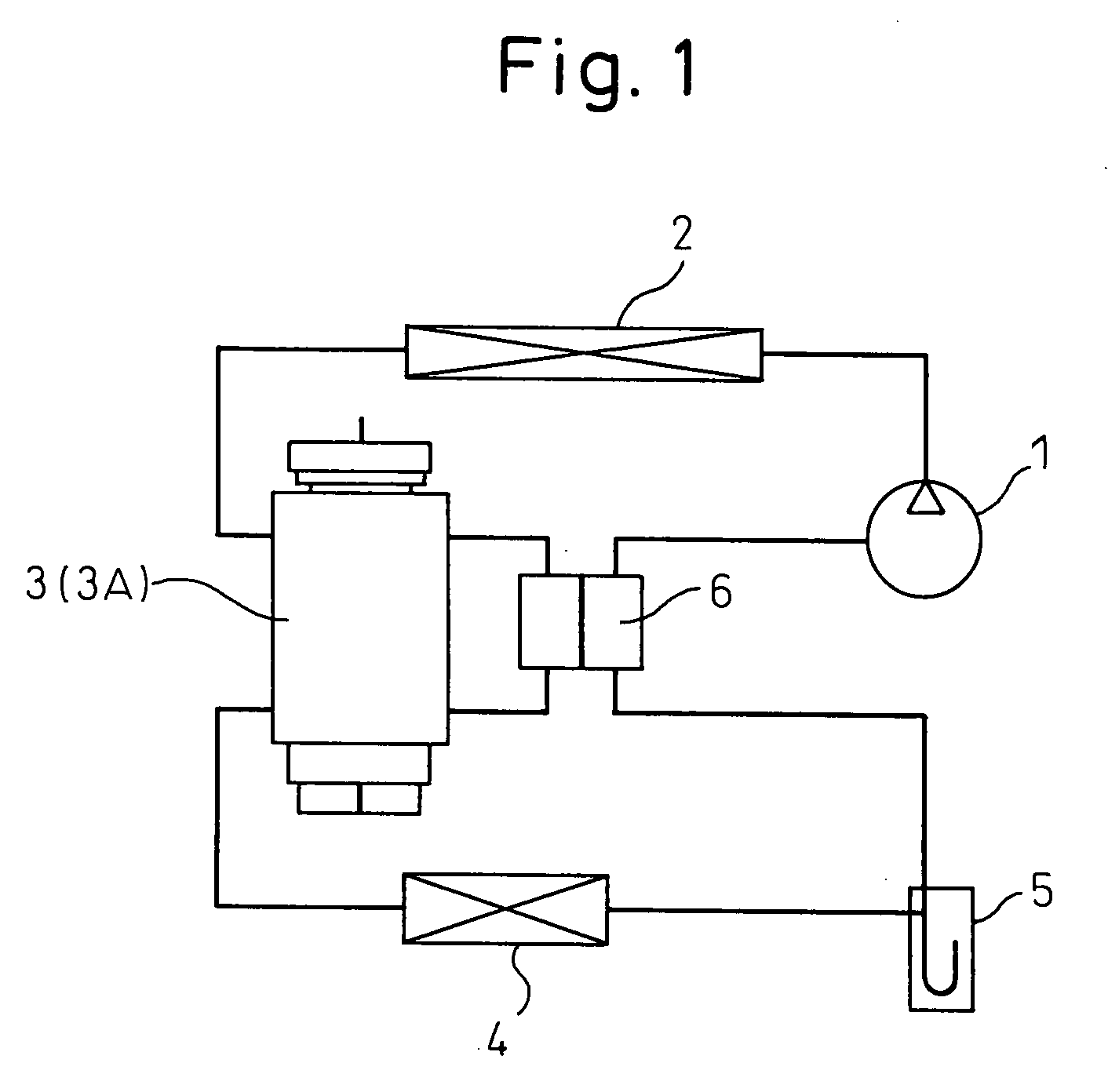

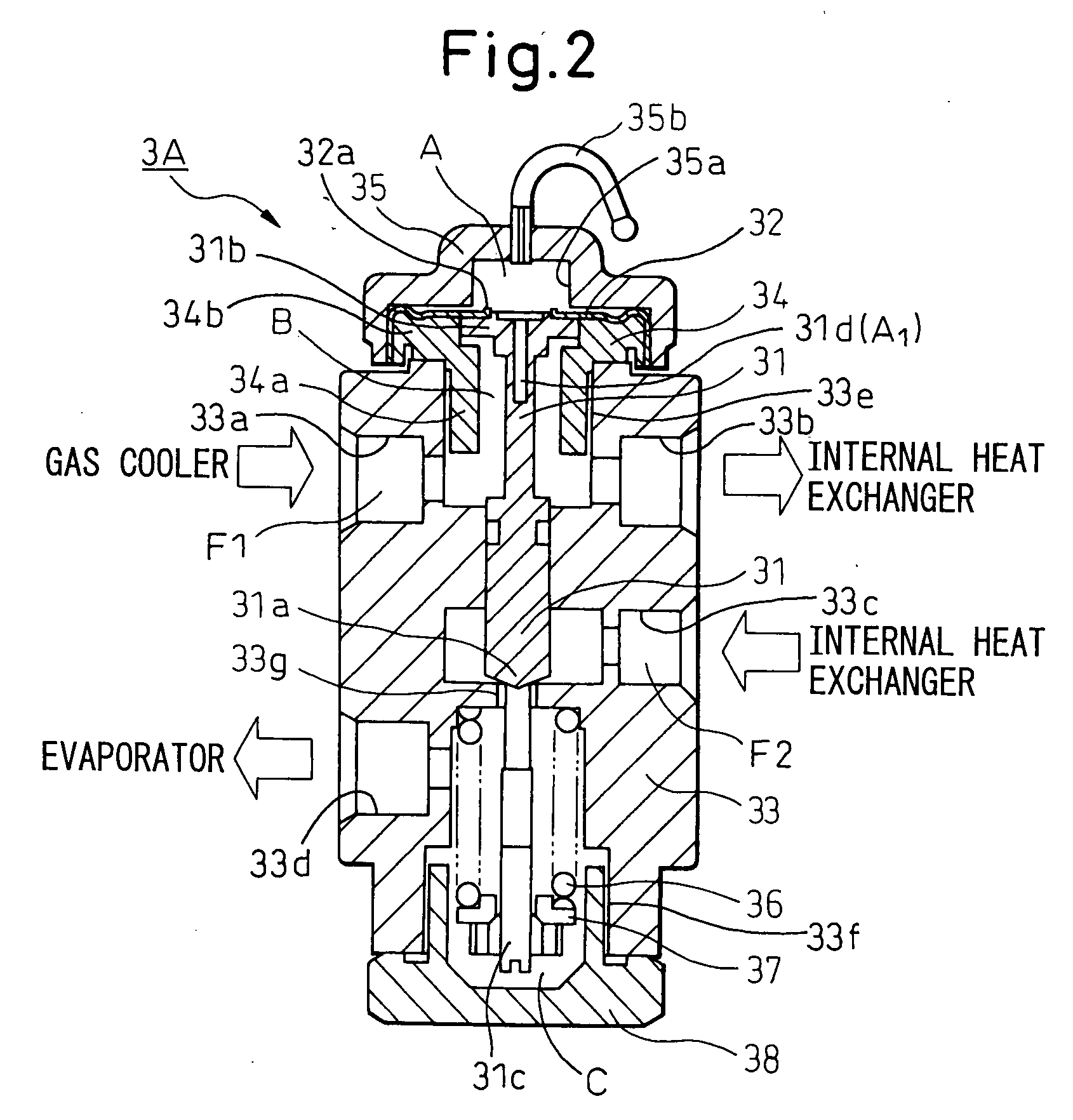

[0041] The pressure controlling valves according to embodiments of the present invention will be hereinafter explained with reference to the drawings. FIG. 1 is an explanatory view explaining a refrigeration cycle (supercritical refrigeration cycle) into which an internal heat exchanger is assembled, and which circulates CO2 as a refrigerant. FIG. 2 shows a pressure controlling valve according to the present invention that is applied to the refrigeration cycle shown in FIG. 1. In FIG. 1, reference numeral 1 denotes a compressor that sucks in and compresses a CO2 refrigerant and reference numeral 2 denotes a gas cooler (heat radiator) that cools the refrigerant compressed by the compressor 1.

[0042] Reference numeral 3 denotes a pressure controlling valve (expansion valve) according to this embodiment. This pressure controlling valve 3 has a temperature sensitive portion (sealed space) A into which CO2 gas is sealed, and controls refrigerant pressure on the exit side of the gas cooler...

second embodiment

[0074]FIG. 3 is an explanatory view useful for explaining the refrigeration cycle of the CO2 refrigerant without incorporating the internal heat exchanger. FIG. 4 shows a pressure controlling valve 3B according to the invention that is applied to the refrigeration cycle shown in FIG. 3. The same reference numeral is used to identify the same constituent member as in FIG. 1. In other words, reference numeral 1 denotes the compressor for sucking and compressing the CO2 refrigerant. Reference numeral 2 denotes the gas cooler for cooling the refrigerant compressed by the compressor 1. The pressure controlling valve 3 (3B) for controlling the refrigerant pressure on the exit side of the gas cooler 2 on the basis of the refrigerant temperature on the exit side of the gas cooler 2 is arranged on the exit side of the gas cooler 2 and operates as a pressure reducing device for reducing the pressure of the high pressure refrigerant.

[0075] Reference numeral 4 denotes the evaporator for evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com