Piston pump

A technology of piston pumps and pistons, which is applied in the direction of piston pumps, pumps, pump components, etc., can solve the problems of insufficient discharge volume, reduced reliability, and deviation of processing dimensions, so as to achieve cost reduction, high reliability, and prevent abnormalities The effect of high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

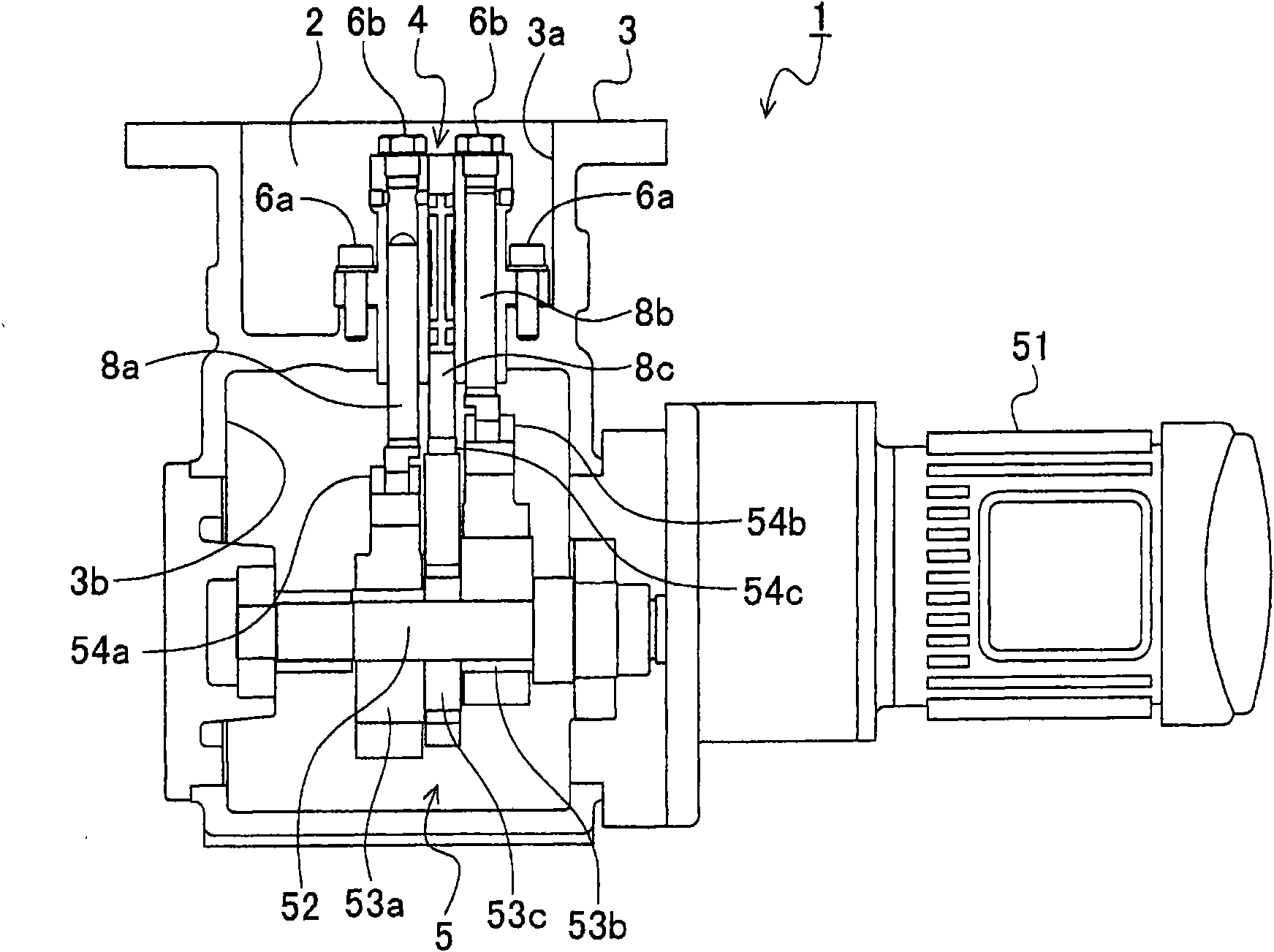

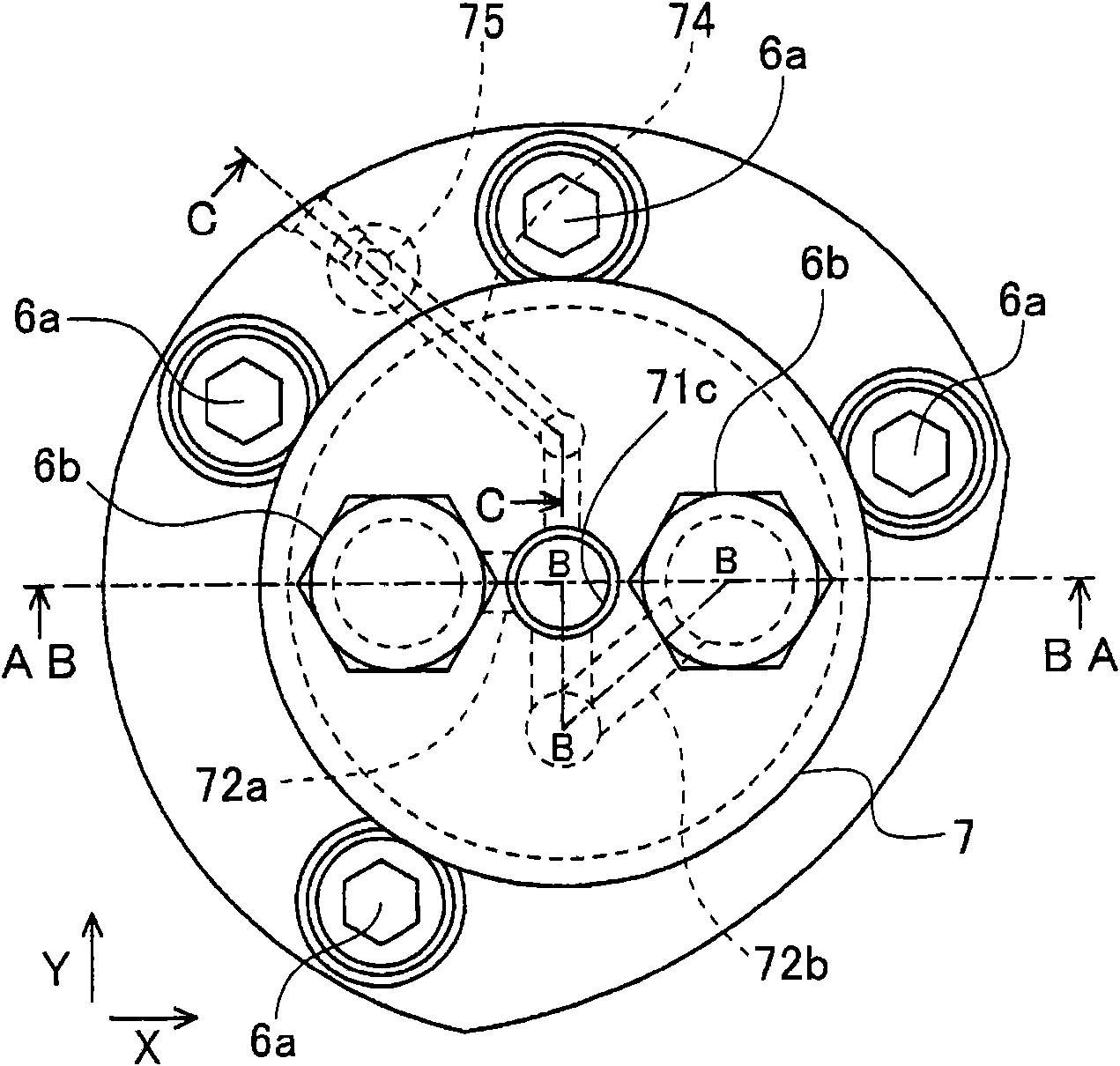

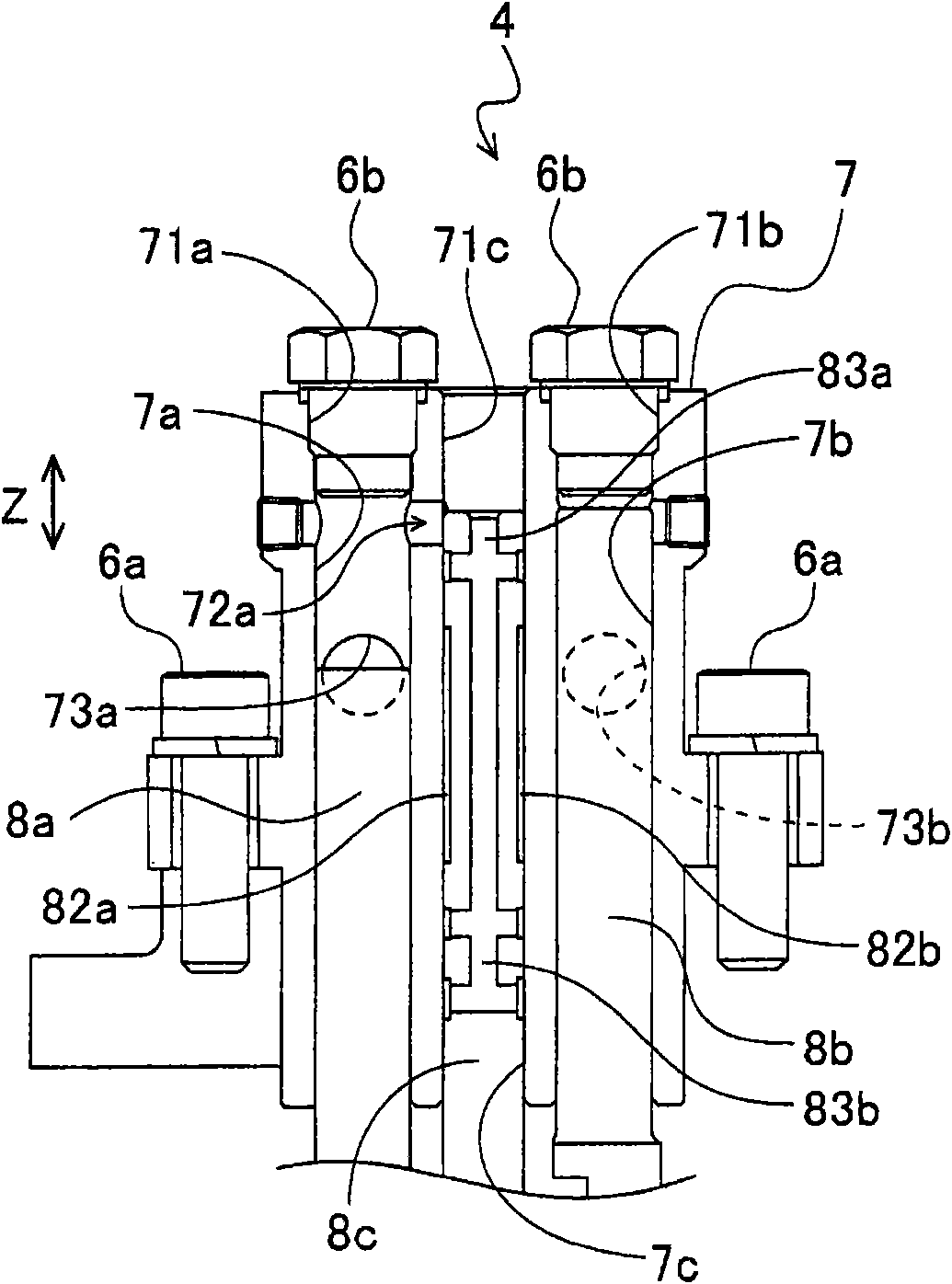

[0091] [Structure of Piston Pump 1 of First Embodiment]

[0092] First, refer to Figure 1 to Figure 6 The structure of the piston pump 1 of the first embodiment will be described in detail. The piston pump 1 of this embodiment has a function of pressurizing and feeding lubricating oil 2 such as grease, and is mainly used in a centralized lubricating oil device. Such asfigure 1 As shown, the piston pump 1 has: a housing 3 having a lubricating oil storage chamber 3a for storing lubricating oil 2; a discharge mechanism part 4 which discharges the lubricating oil 2 stored in the lubricating oil storage chamber 3a; The mechanism part 5 drives the discharge mechanism part 4 .

[0093] The lubricating oil storage chamber 3a is provided in the upper part of the housing 3, and the drive chamber 3b which accommodates the drive mechanism part 5 is provided in the lower part. The discharge mechanism part 4 is attached to the bottom of the lubricating oil storage chamber 3a via a plura...

no. 2 approach

[0135] [Structure of Piston Pump 1 of Second Embodiment]

[0136] First, refer to Figure 13 The structure of the piston pump of the second embodiment will be described in detail. In addition, below, the same code|symbol as 1st Embodiment shows the same structure as 1st Embodiment.

[0137] In this second embodiment, the configuration other than the discharge mechanism is the same as that of the above-mentioned first embodiment, and therefore description thereof will be appropriately omitted. Such as Figure 13 As shown, in the main body portion 107 of the discharge mechanism portion 104 of the piston pump according to this embodiment, a suction passage 176 having a suction port 177 for sucking the lubricating oil 2 from the oil tank line is provided. This suction passage 176 communicates with a connection passage 183b formed in a pilot piston 108c described later, thereby communicating with the piston chamber 7c and the lubricating oil storage chamber 3a.

[0138] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com