Multi-position work stand

a multi-position, work platform technology, applied in the field of work platforms, can solve the problems of bulky and heavy present equipment for holding these items, and achieve the effect of convenient, easy and quick configuration and us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

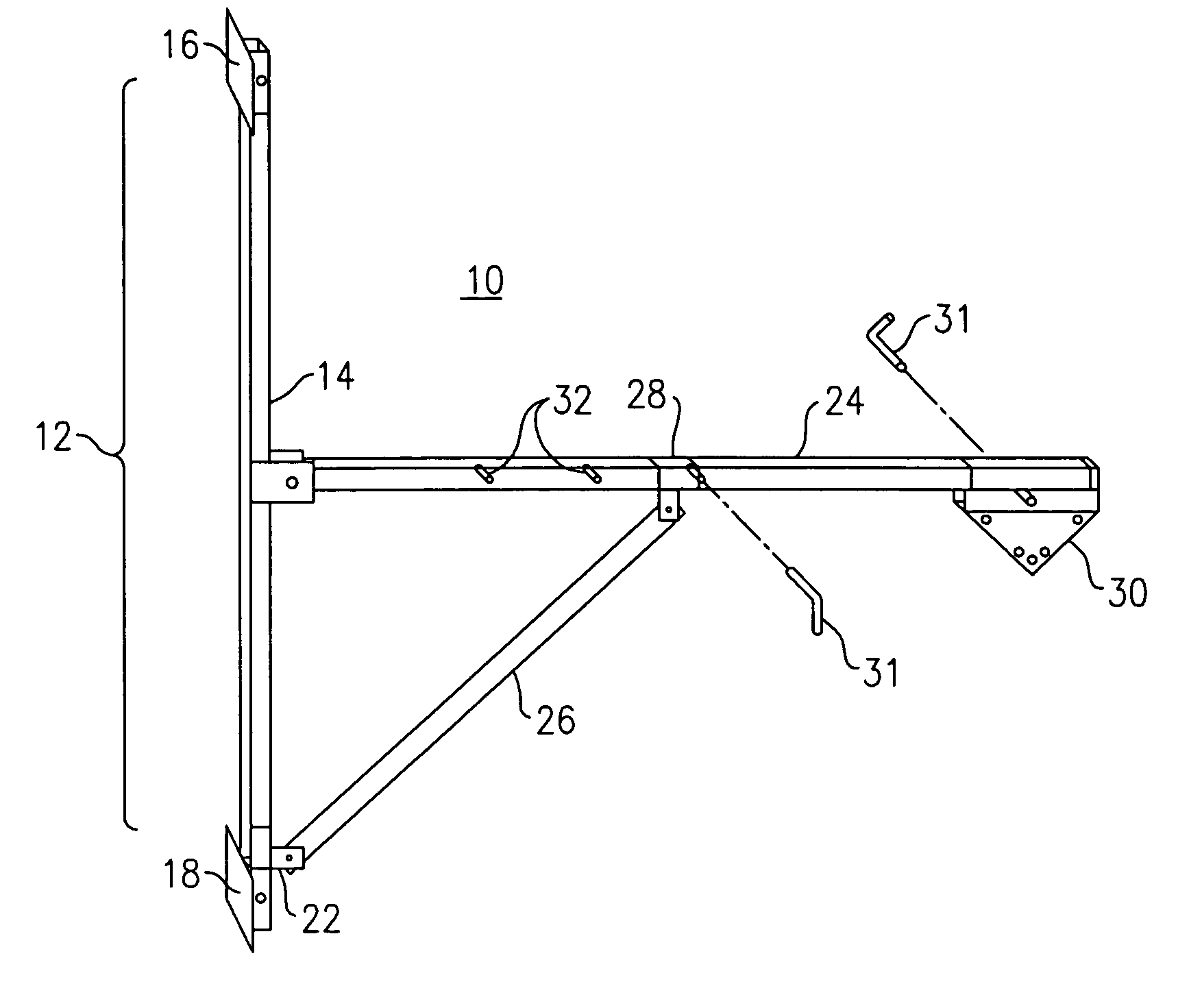

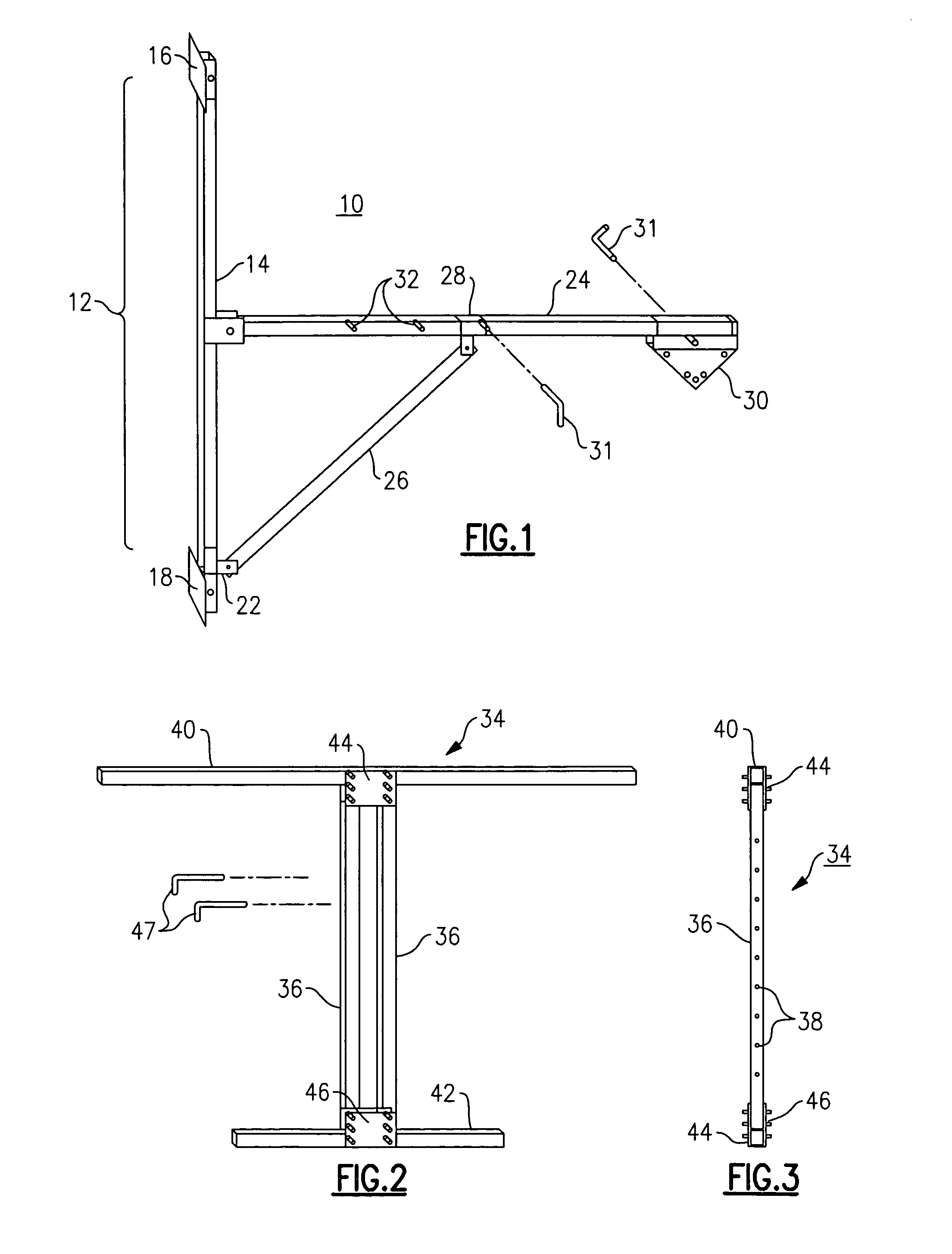

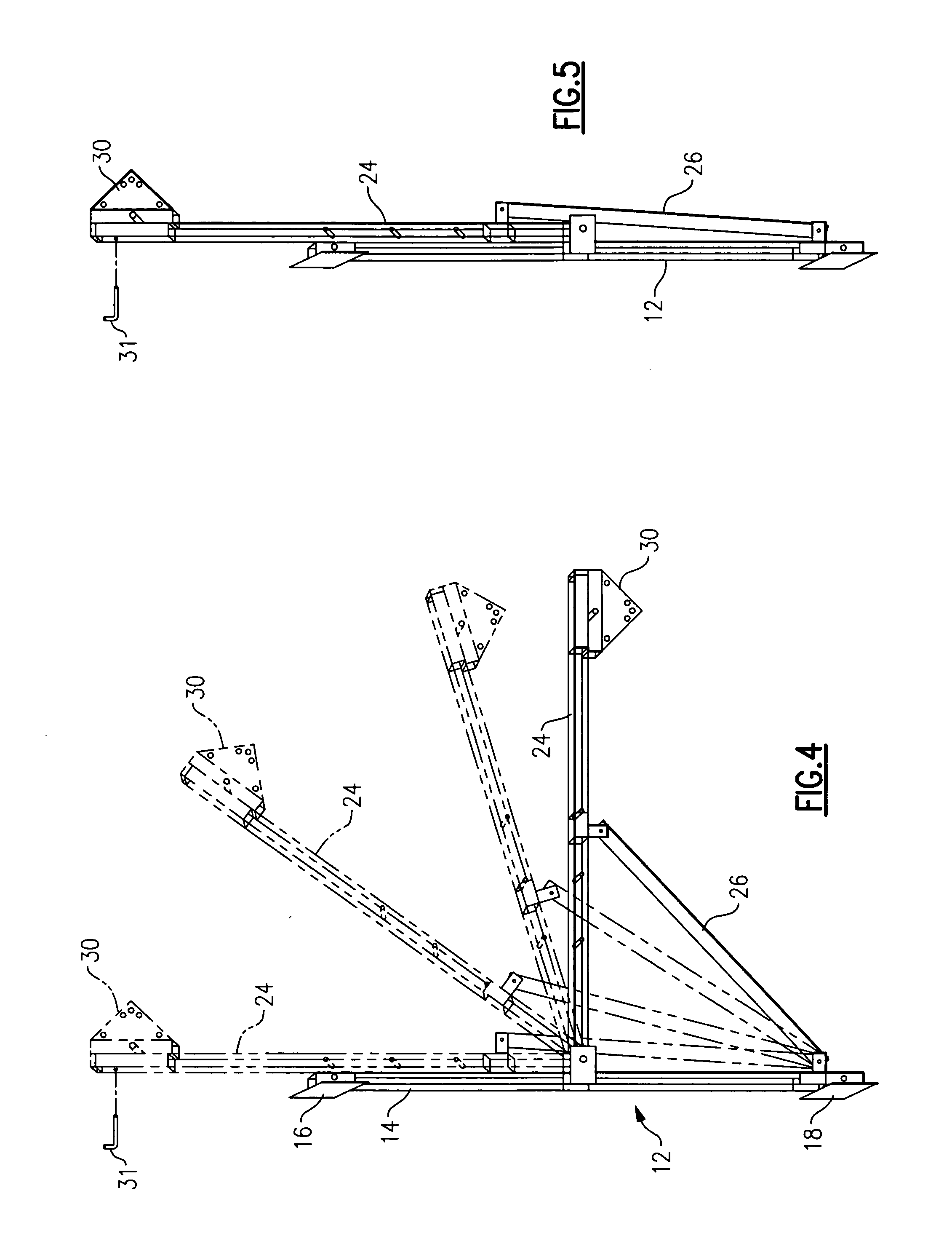

[0023]With reference to the Drawing, and initially to FIGS. 1 to 3 thereof, one preferred embodiment of the work stand 10 has a wall mounted base 12, which here is formed of a vertical rail member 14 with upper and lower wall mounting brackets 16 and 18. Mounted on the vertical rail member 14 are an upper pivot member 20 and a lower pivot member 22. In this embodiment, the upper pivot member 20 is situated in the middle portion of the rail member and the lower pivot member 22 is at the lower end. A swing-up support arm 24 is implemented as an elongated rail member formed of a length of square tubular steel. One end of the arm 24, i.e., a pivot end, is journaled in the upper pivot member 20, and its other end is considered its free end. A strut member 26 has one end, i.e., a lower end. pivotally supported in the lower pivot member, and its other end, i.e., its upper end, is attached to a slide bracket or sleeve 28 that is slidably mounted onto the support arm 24. A nosepiece 30 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com