Snowplow formed of thermoplastic

a technology of thermoplastic snowplows and snowplow assemblies, which is applied in the direction of snow cleaning, way cleaning, construction, etc., can solve the problems of large metal content of snowplow assemblies, inability to fit light vehicles, and large metal content of snowplows, etc., to achieve the effect of easy and efficient formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

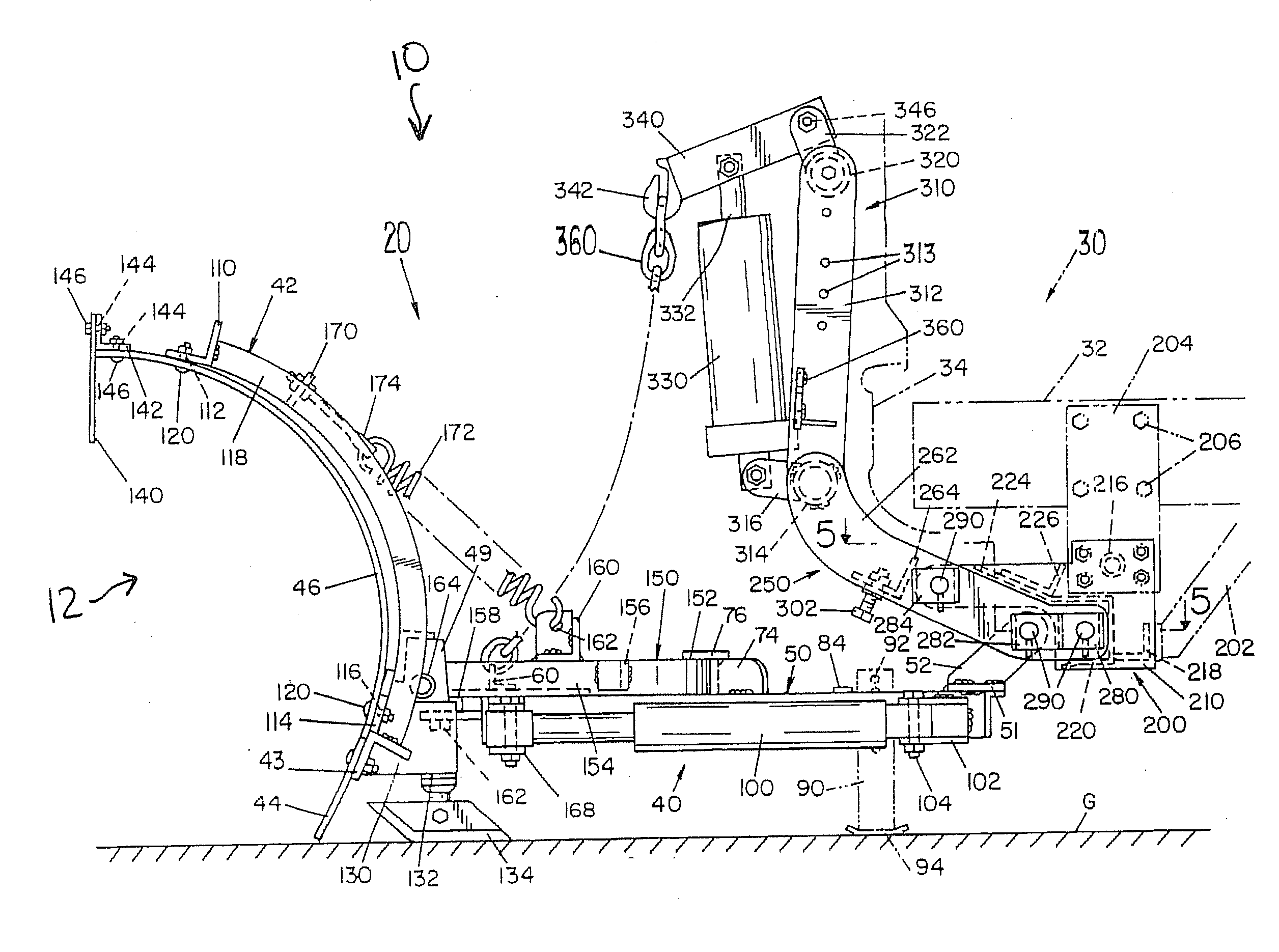

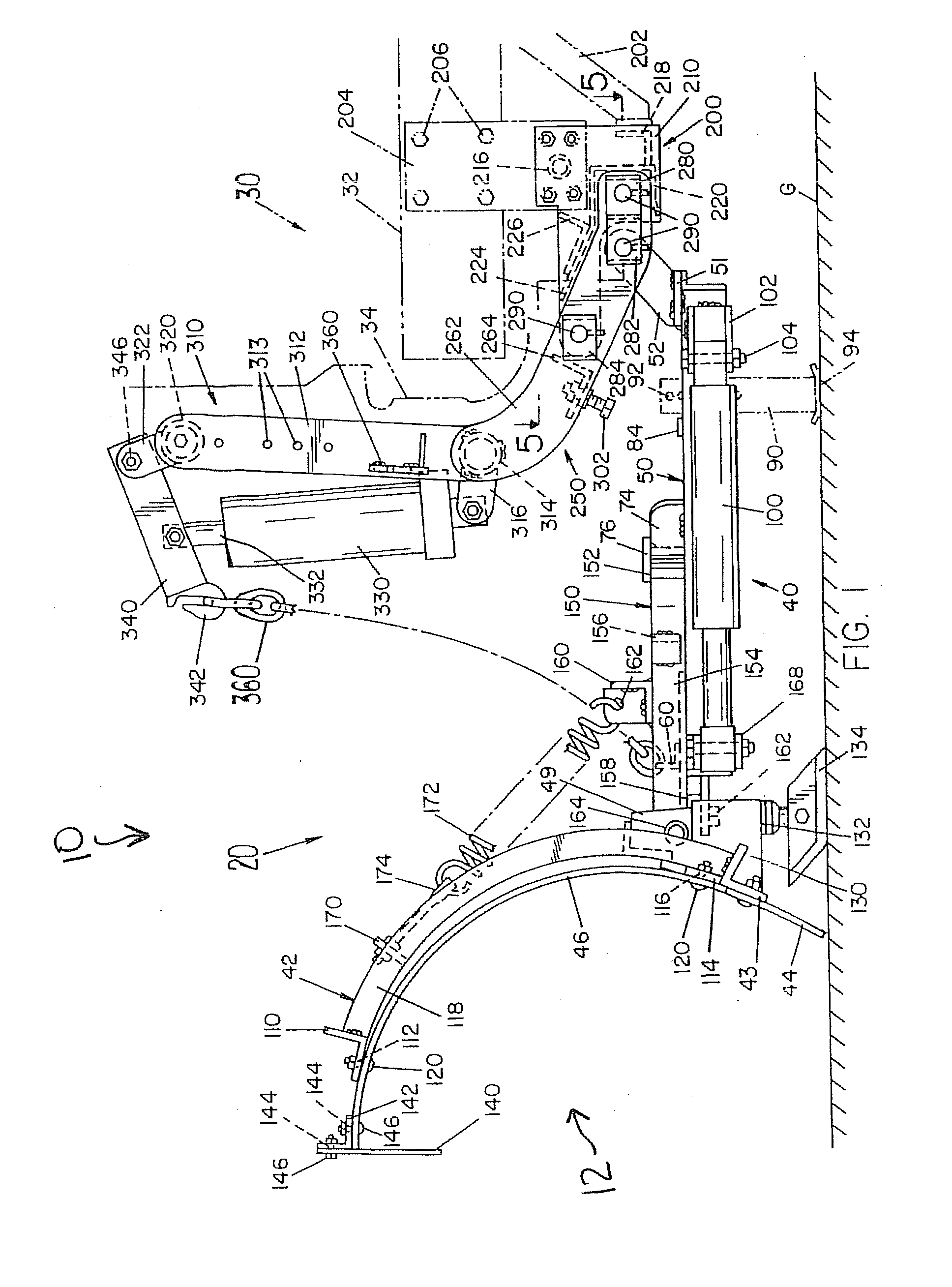

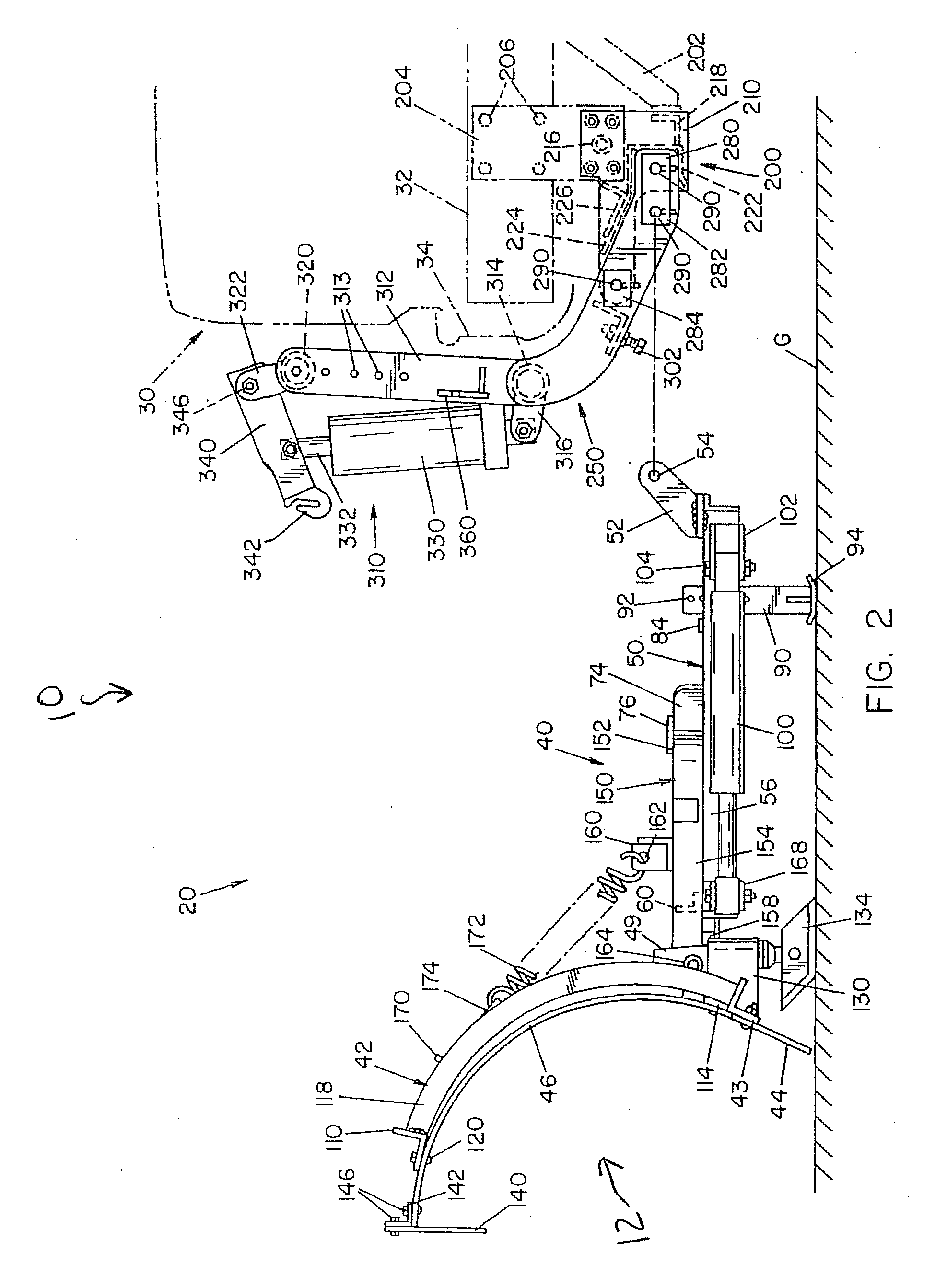

[0024]Referring now to the drawings wherein the showings are for purposes of illustrating embodiments of the invention only and not for purposes of limiting the same, FIG. 1 shows a vehicle 30 equipped with the inventive snowplow assembly 10 of this invention. The snowplow assembly 10 may be used for snow removal operations such as those encountered in plowing driveways, parking lots, roads, etc. It should be noted that while the snowplow assembly 10 of this invention is much lighter in weight than previously known snowplow assemblies and thus especially useful for relatively light vehicles 30 such as automobiles, mini-vans and support utility vehicles (SUVs), it can be used with any vehicle 30 including trucks, tractors or the like.

[0025]With reference to FIGS. 1-4, the snowplow assembly 10 may include a snowplow mechanism 12 having an inwardly curved mold board 46, a generally longitudinally extending structural frame 42, a scraper blade 44 which may be attached to the bottom of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com