Flexible toroidal reel

a toroidal reel and flexible technology, applied in the field of flexible toroidal reels, can solve the problems of flattening the wound material, breaking and chipping along the circumference, and severely weakening the reel at the flange to the barrel joint, etc., to achieve convenient pipe bending, secure confinement of wound material, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

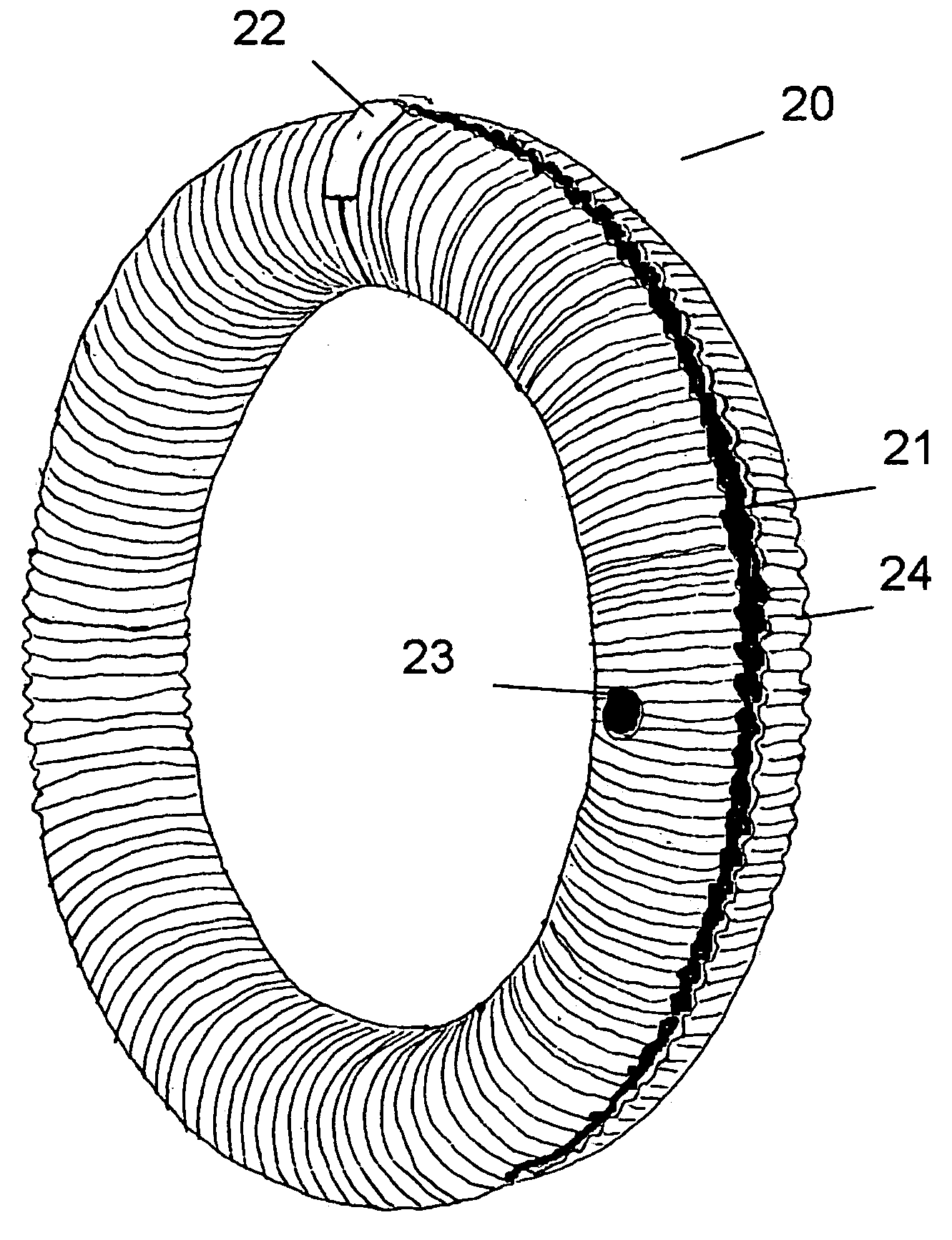

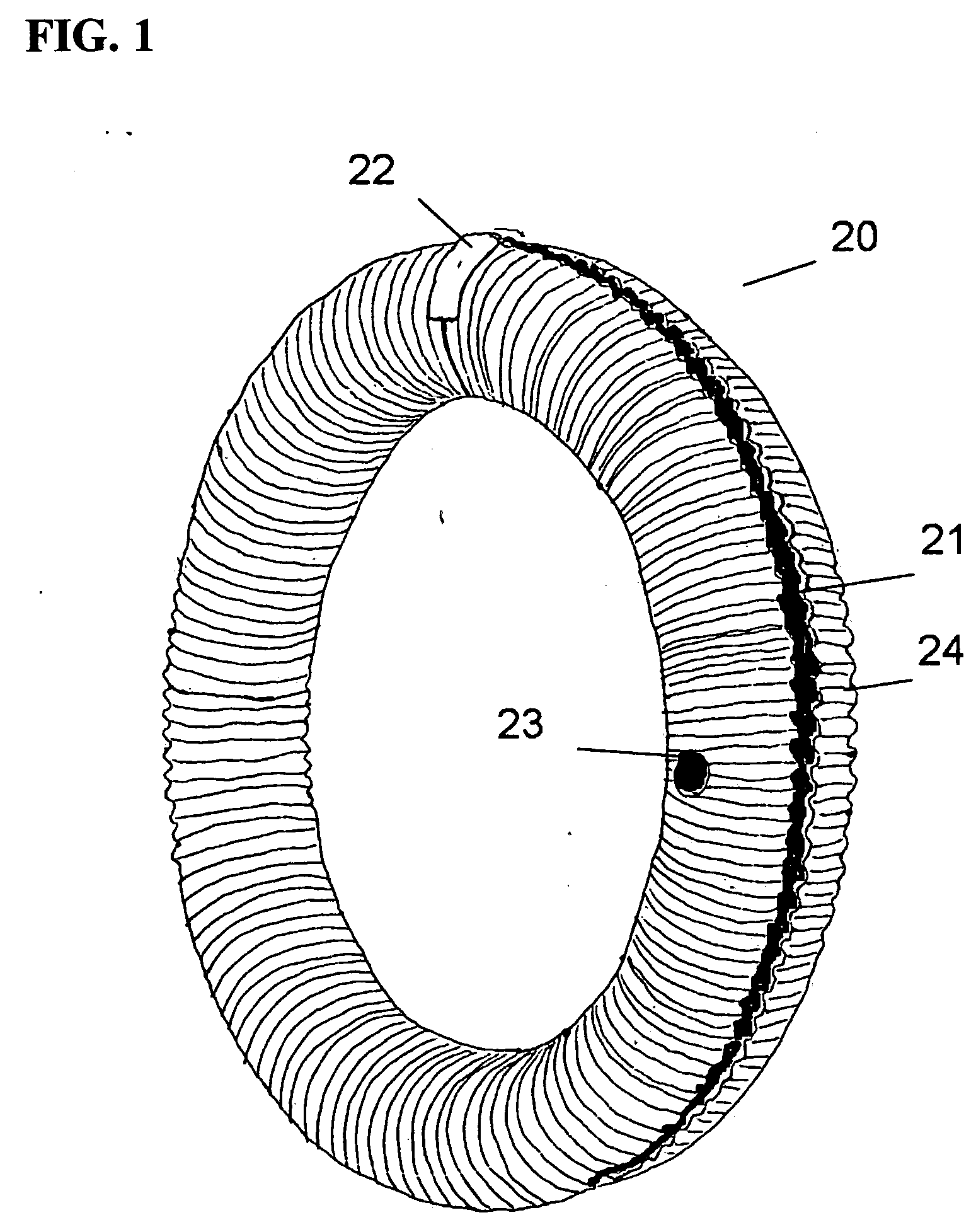

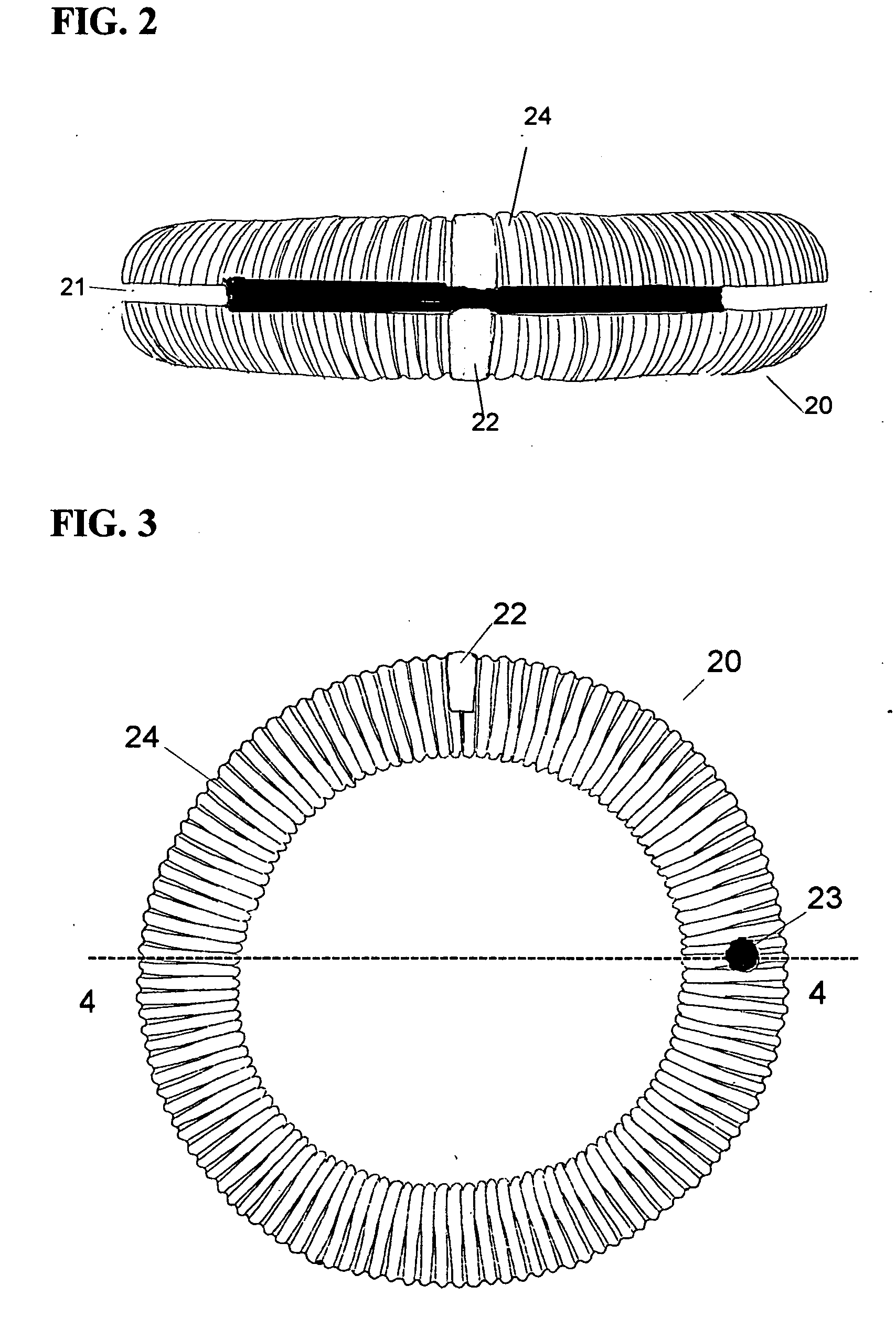

[0029] Referring to the Figures and particularly to FIG. 1, a reel 20 is made from a split corrugated plastic drainage pipe welded, fastened or coupled end to end forming a hollow torus with a slit 21 opening on its circumference through which material can be wound on its interior surface. In some embodiments of the present invention reel 20, at least one start hole 23 is provided which extends through the reel shell to provide external access to one end of the wound material and fix that end to the reel 20 so winding can commence. Therefore, the start hole 23 is appropriately sized to allow passage of a hose end or extension cord plug and provide bearing engagement between the edge of the hole 23 and the wound material.

[0030] In some embodiments of the present invention reel 20, two or more coupling sleeves 22 join the two ends of the corrugated pipe to form the reel 20. The sleeves 22 slide transversely over the rib 24 at each end of the corrugated plastic drainage pipe thereby l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com