Cutting Tool Holding Apparatus And Method Of Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

[0056] In addition terms such as “front”, “back”, “base”, “top”, “side”, “bottom”, “end”, “rear”, “underside” etc. refer to the orientation or configuration of a cutting tool holding apparatus when used according to the illustrations and to assist in indicating points of reference when viewing the accompanying figures. It is to be understood that these terms do not limit the present invention to any specific orientation or configuration of the invention.

[0057] In the specification the terms “comprising” and “containing” shall be understood to have a broad meaning similar to the term “including” and will be understood to imply the inclusion of a stated integer or step or group of integers or steps but not the exclusion of any other integer or step or group of integers or steps. This definition also applies to variations on the terms “comprising” and “containing” such as “comprise”, “comprises”, “contain” and “contains”.

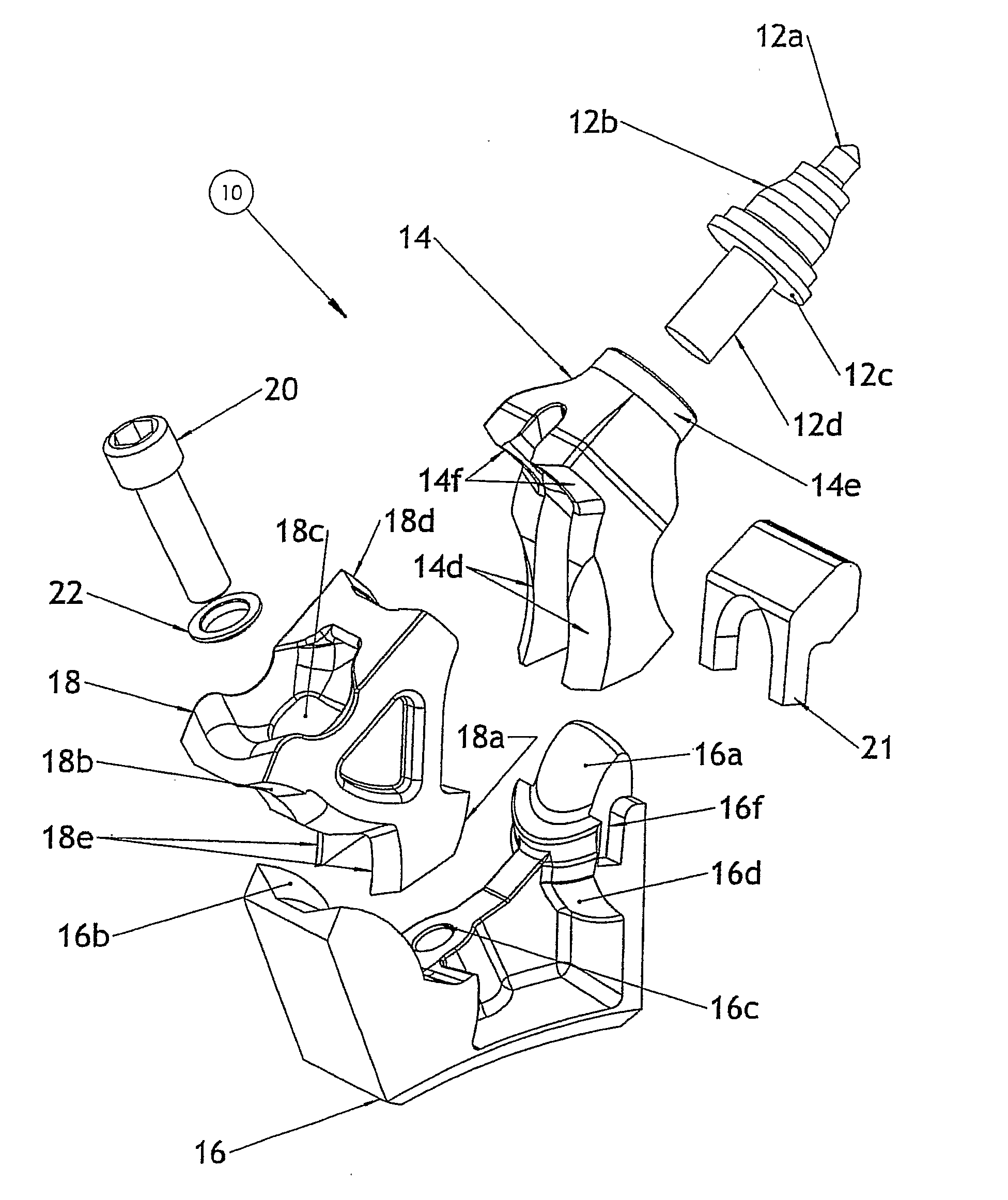

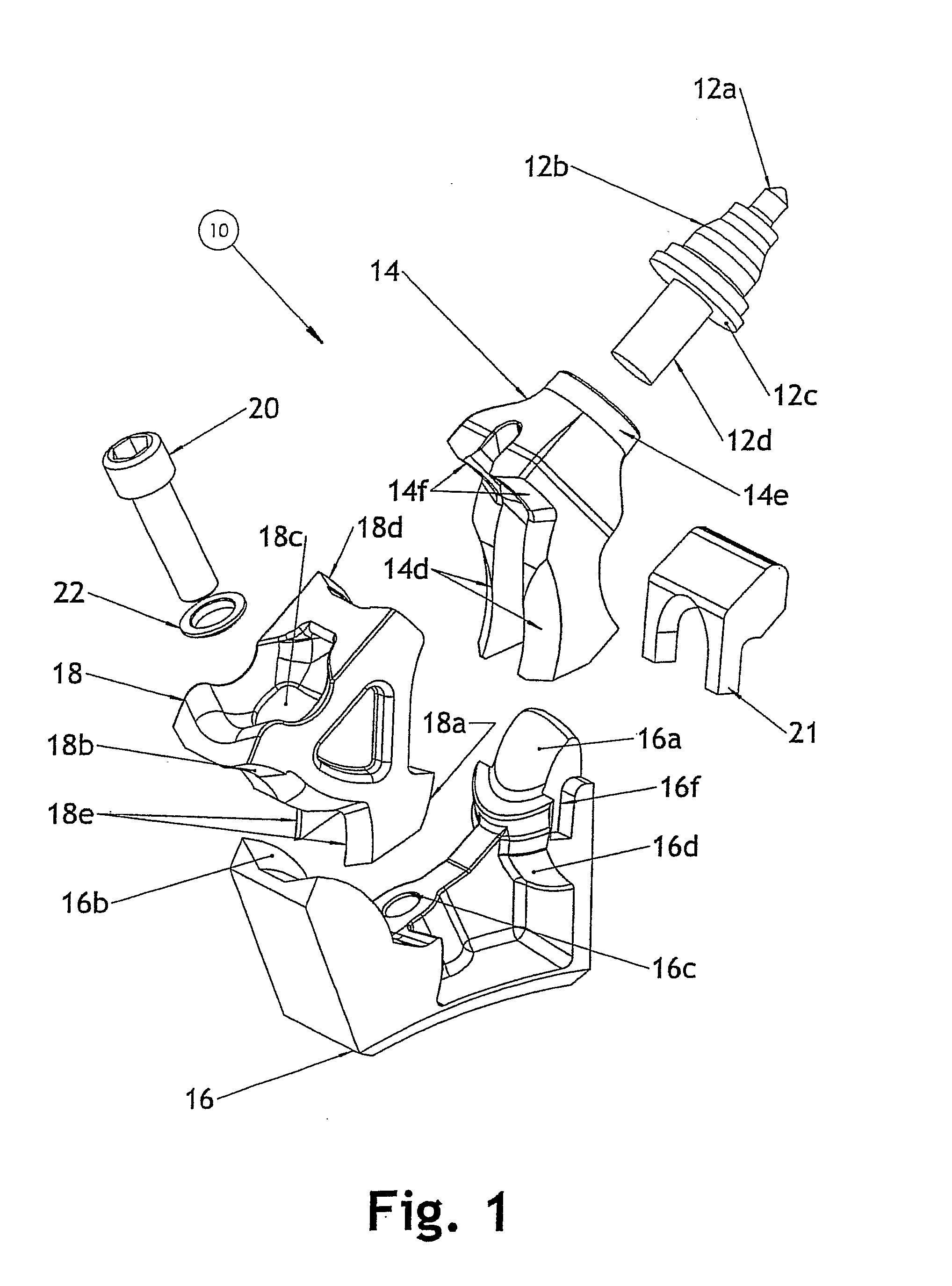

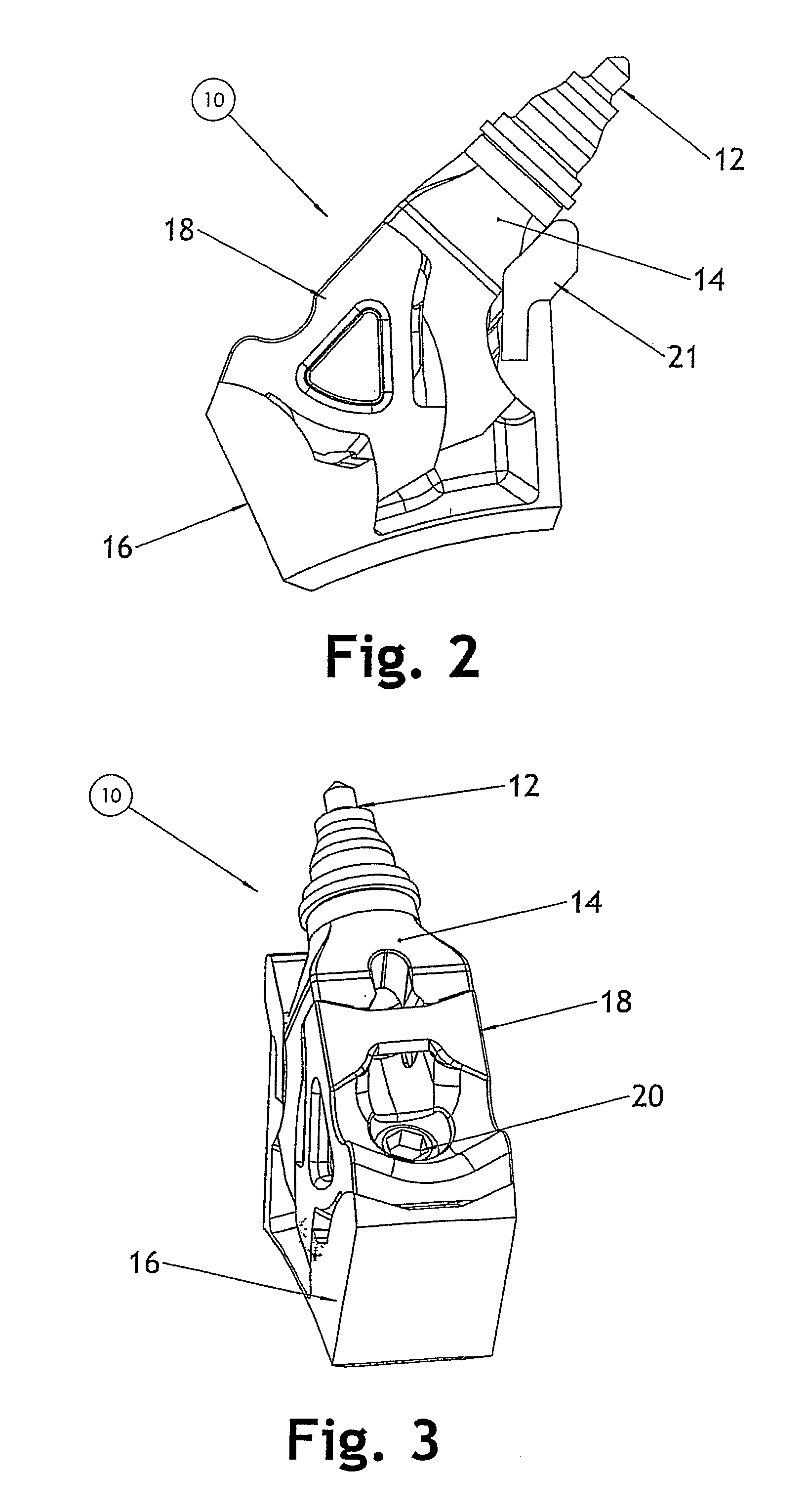

[0058]FIGS. 1-11 illustrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com