Nozzle Structure of Dish Washer

a technology of nozzle structure and dish washer, which is applied in the field of dish washer, can solve the problems of increasing complicated assembly process, and achieve the effects of reducing the manufacturing cost of the check valve, simple structure, and easy assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to accompanying drawings.

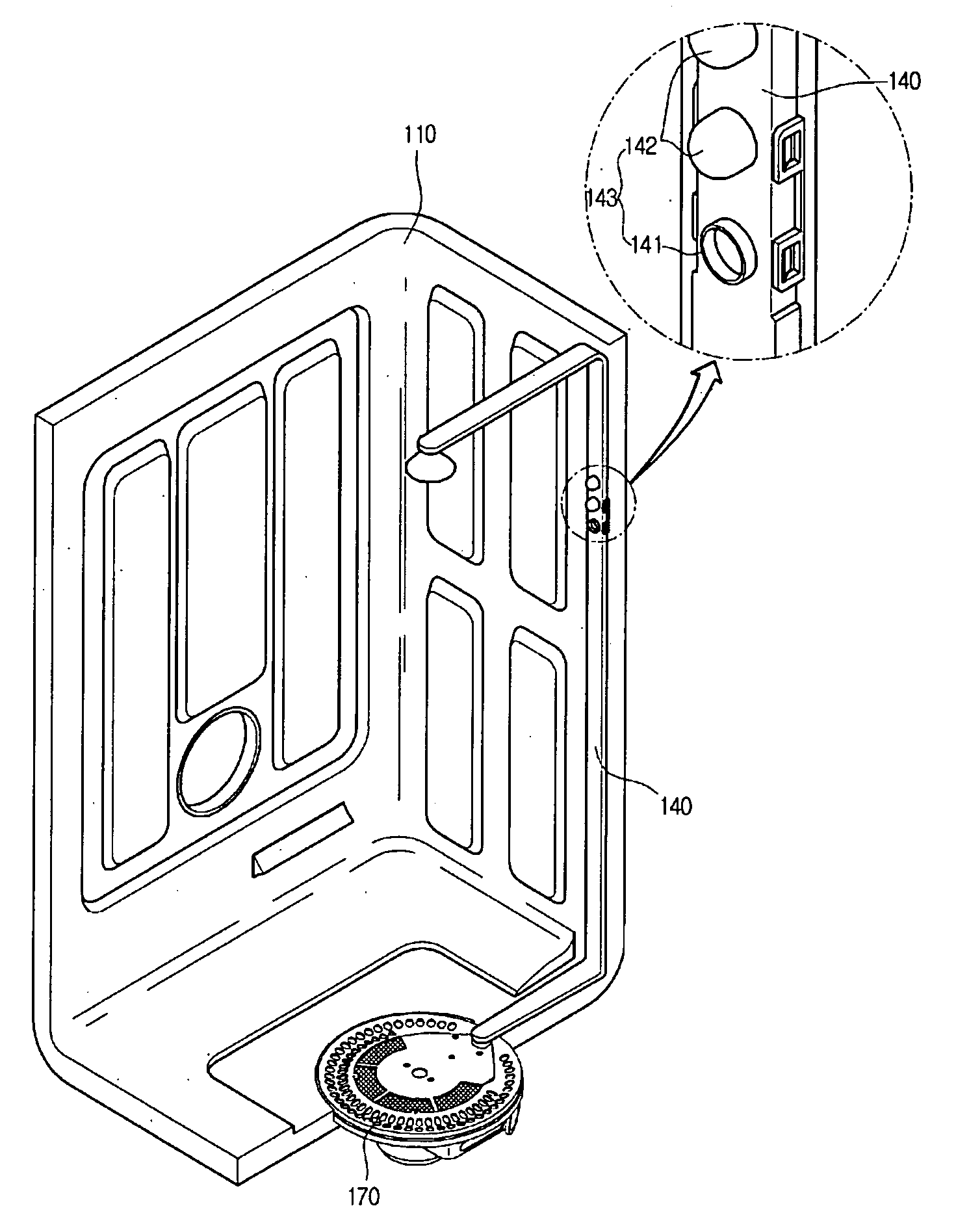

[0022]FIG. 1 is a side sectional view of a dish washer equipped with a nozzle according to the present invention.

[0023]Referring to FIG. 1, the dish washer 100 having a nozzle of the present invention includes an enclosing cabinet 111, a tub 110 installed in the cabinet 111 to define a dish washing chamber, a door 101 installed in front of the tub 110 to open and close the dish washing chamber, and a sump 170 installed on a bottom center of the tub 110 to store washing water.

[0024]Further, the dish washer 100 includes a pump 180 and a motor 190. The pump 180 is connected to the sump 170 to pump washing water contained in the sump 170, and the motor 190 is connected to the pump 180 from a lower side to drive the pump 180.

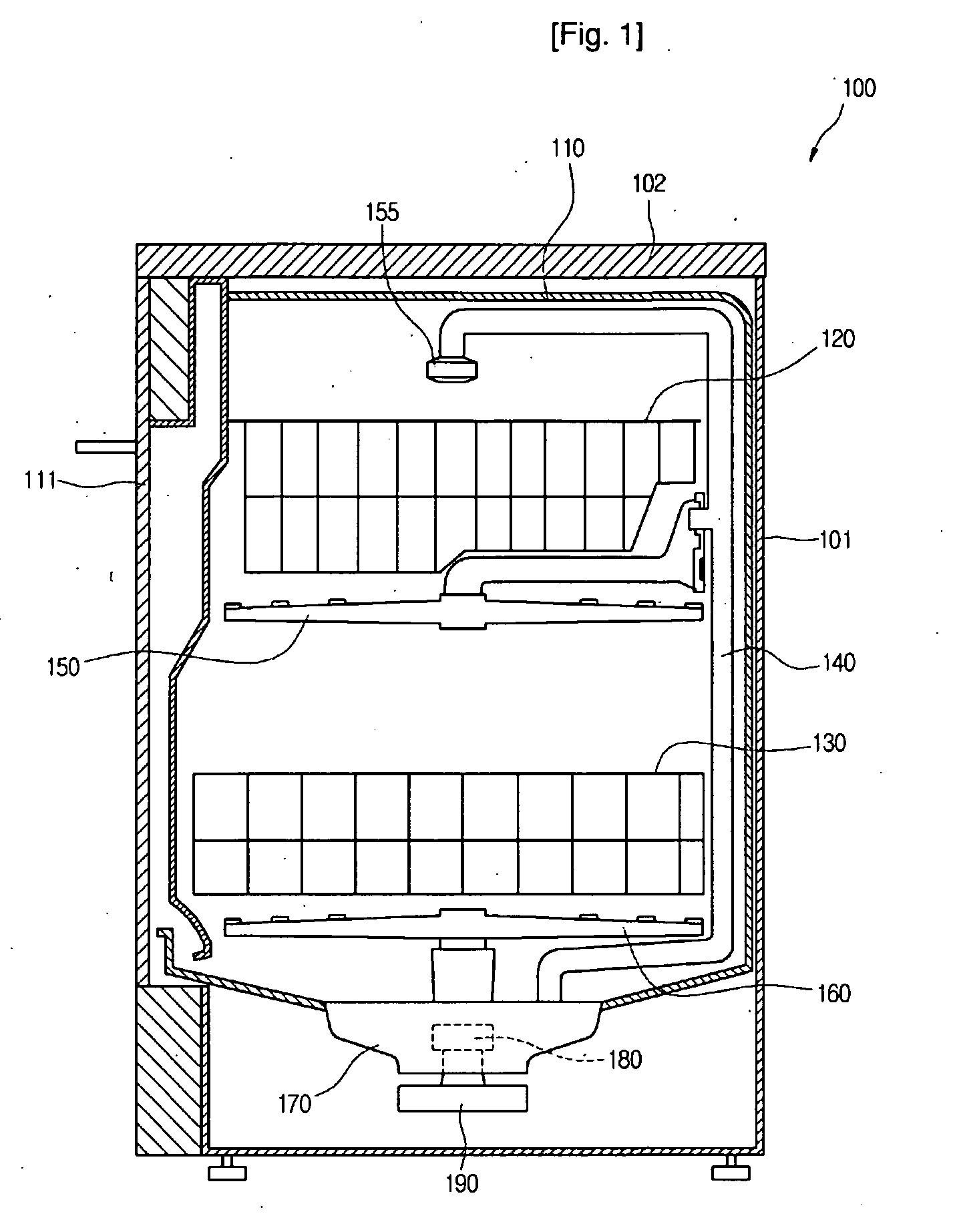

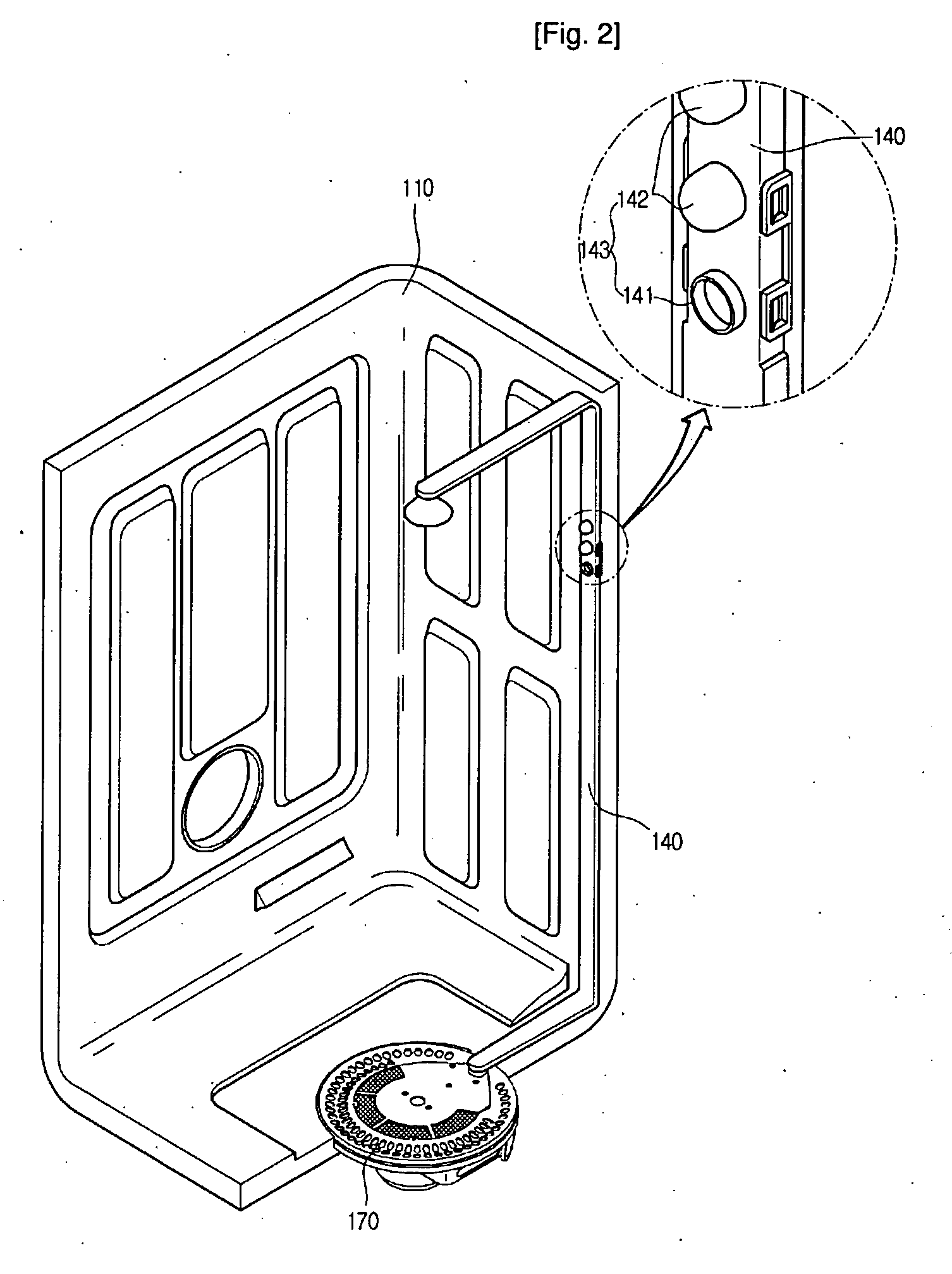

[0025]Further, the dish washer 100 includes a water guide 140 defining a flowing path of the washing water pumped out by the pump 180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com