Golf bag sustained with leg means

a golf bag and leg means technology, applied in the field of golf bags sustained with legs, can solve the problems of increasing the overall cost, unable to dismantle the golf bag from the base for replacement, and the support piece is easily damaged, etc., to achieve the effect of convenient replacement, convenient and simple assembly, and flexible arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

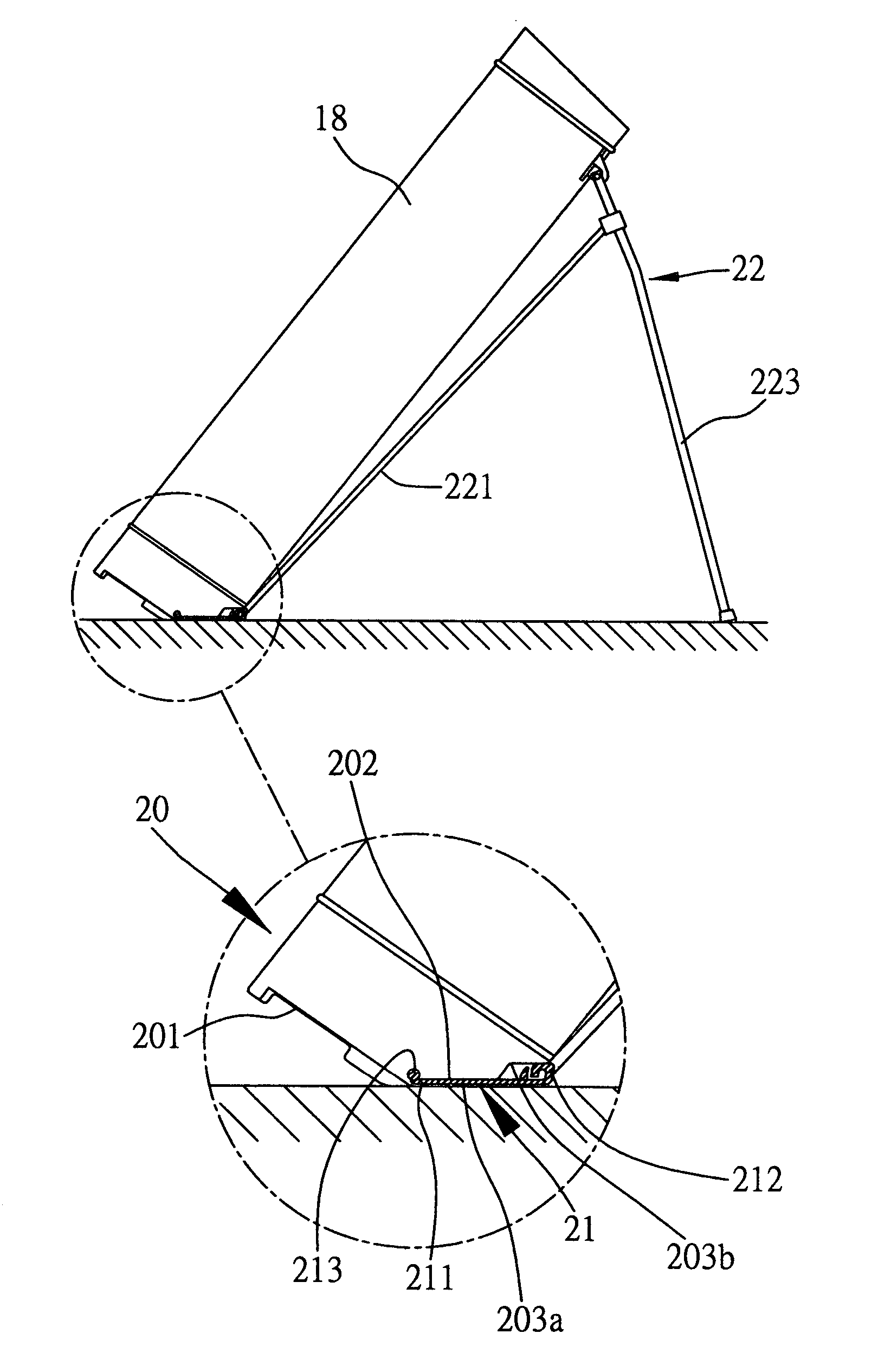

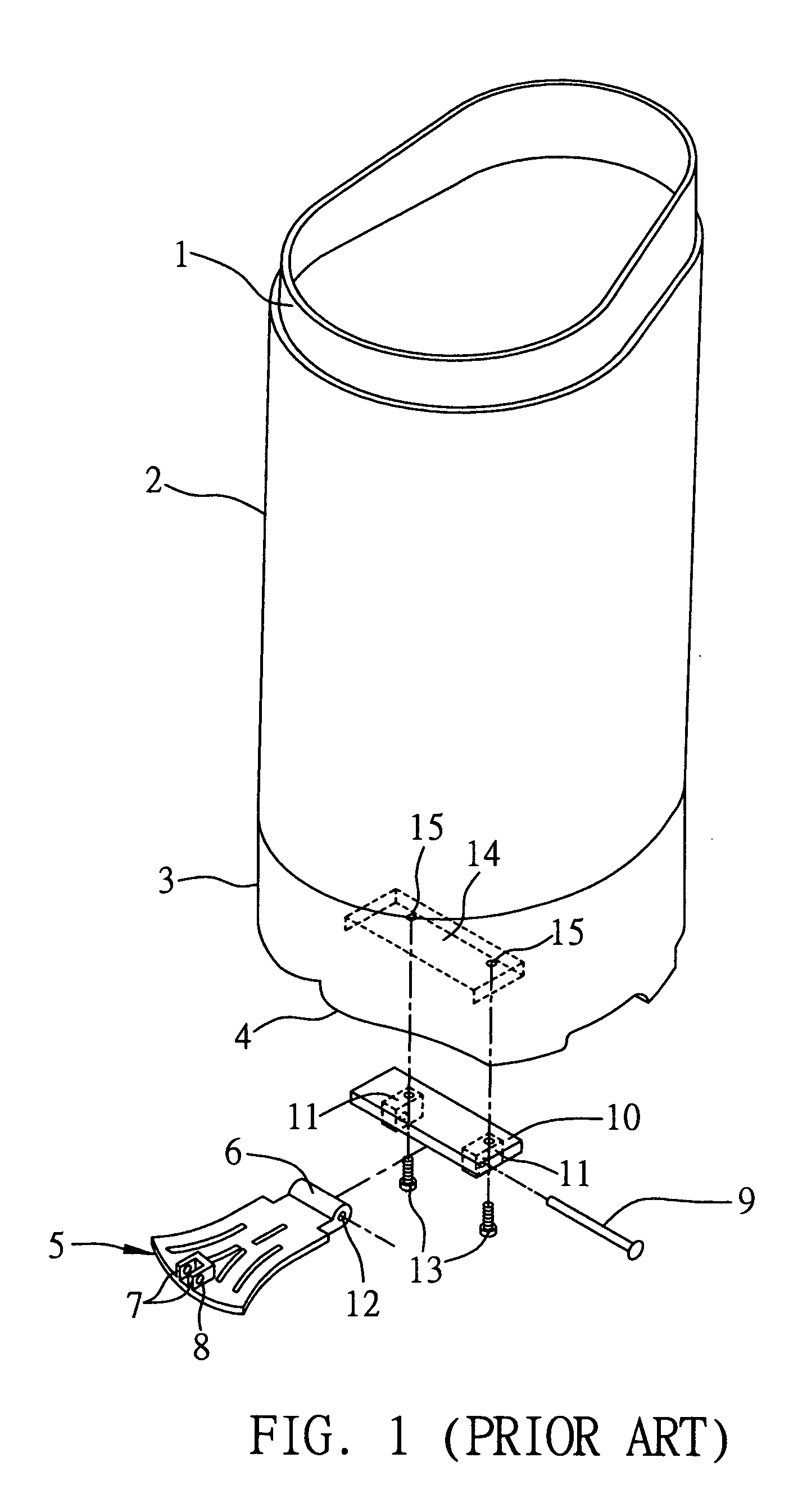

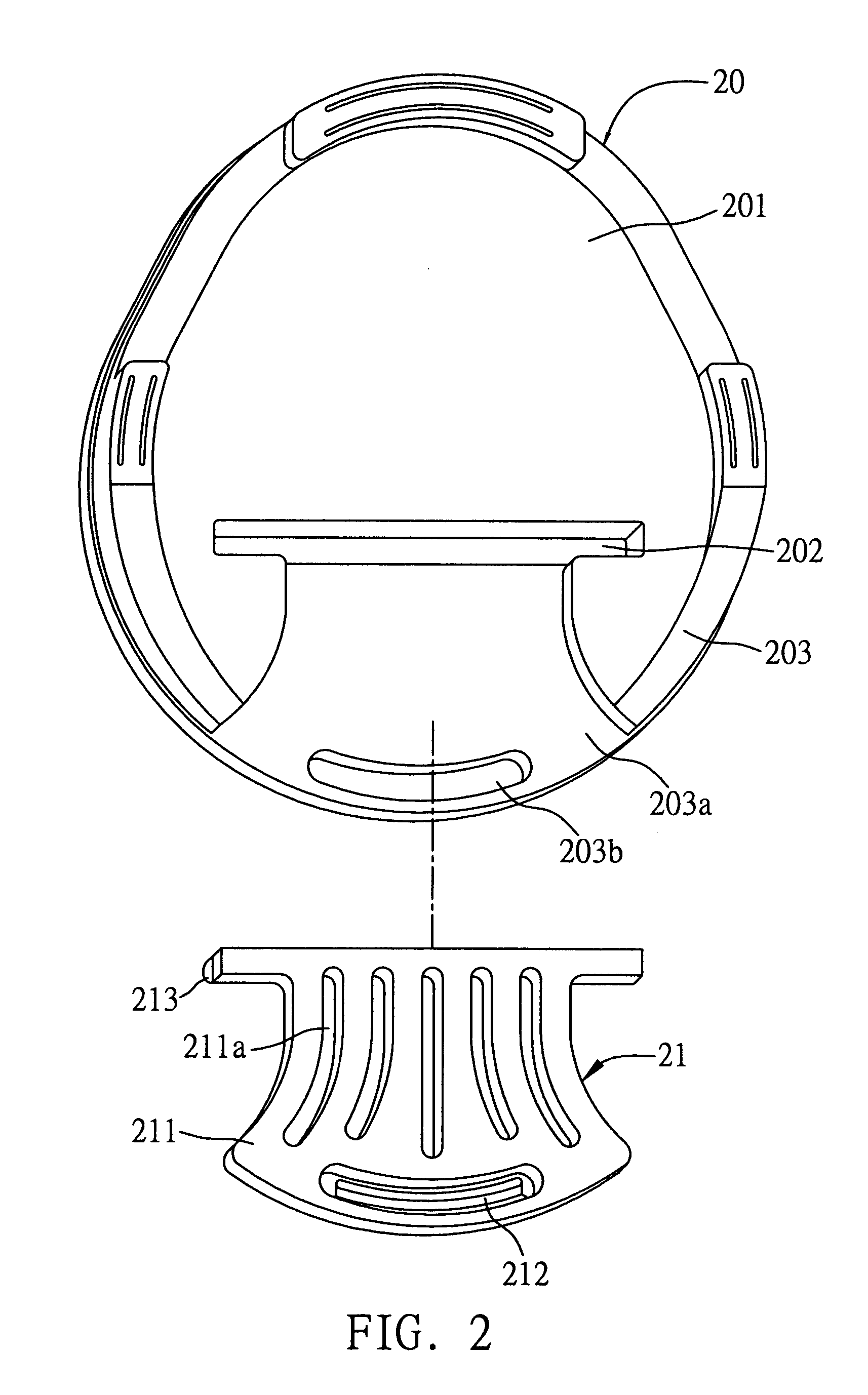

[0026] FIGS. 2 to 4 show a golf bag sustained with leg means according to a first preferred embodiment of the present invention. This golf bag comprises a bag body 18 for storing golf clubs (not shown), a base 20 mounted at the bottom of the bag body 18, and a support piece 21 detachably mounted at the bottom of the base 20.

[0027] As shown in FIGS. 2 to 4, the base 20 comprises a flat surface portion 201, an anchored portion 202 and an inclined plane portion 203. The anchored portion 202 is substantially a parallelogram-shaped opening. The inclined plane portion 203 is formed with a first recess portion 203a and a second recess portion 203b.

[0028] The support piece 21 comprises a flat sheet 211, a first fastening portion 212 and a second fastening portion 213. The flat sheet 211 is formed with one or more hollow portions 211a. The first fastening portion 212 is located at one end of the flat sheet 211 and can be assembled with a support member 221 of the leg means 22. The second f...

second preferred embodiment

[0033]FIGS. 5 and 6 show the golf bag sustained with leg means according to a second preferred embodiment of the present invention. This golf bag comprises a bag body 18 for placing golf clubs (not shown), a base 30 on the bottom of the bag body 18, and a support piece 31 detachably mounted at the bottom of the base 30.

[0034] The golf bag of this second preferred embodiment is substantially the same in structure as that of the above first preferred embodiment, but differs in that the anchored portion 302 of the base 30 and the second fastening portion 313 of the support piece 31 are saw-shaped structures corresponding to each other. Further, the support piece 31 has a first flat sheet 311a and a second flat sheet 311b extending from a side of the first flat sheet 311a, and the second fastening portion 313 is located at the side of the first flat sheet 311a connected with the second flat sheet 311b.

[0035] The saw-shaped second fastening portion 313 comprises saws 313a and hollow po...

third preferred embodiment

[0041]FIGS. 7 and 8 show the golf bag according to a third preferred embodiment of the present invention. The leg means for sustaining the golf bag is the same as those in the first and second preferred embodiments and thus is not illustrated in the drawings here.

[0042] The golf bag in this third preferred embodiment is substantially the same in structure as that of the above first preferred embodiment, with the only difference in that the anchored portion 402 of the base 40 is formed with symmetric openings 403 and 404. The second fastening portion 413 of the support piece 41 is a cylindrical structure shaped correspondingly to the openings 403 and 404 of the anchored portion 402. The support piece 41 further comprises a flat sheet 411 with an elastic portion 412.

[0043] The elastic portion 412 provides a larger elastic area for the second fastening portion 413, allowing the second fastening portion 413 to be elastically coupled to the anchored portion 402. With the provision of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com